Power a-frame

a technology of supporting racks and supports, applied in the direction of machine supports, furniture parts, packaging goods types, etc., can solve the problems of occupying a lot of space, affecting the use of sawhorses, and heavy sheeting, and achieves the effects of convenient use, convenient use, and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Detailed Description of the Drawings

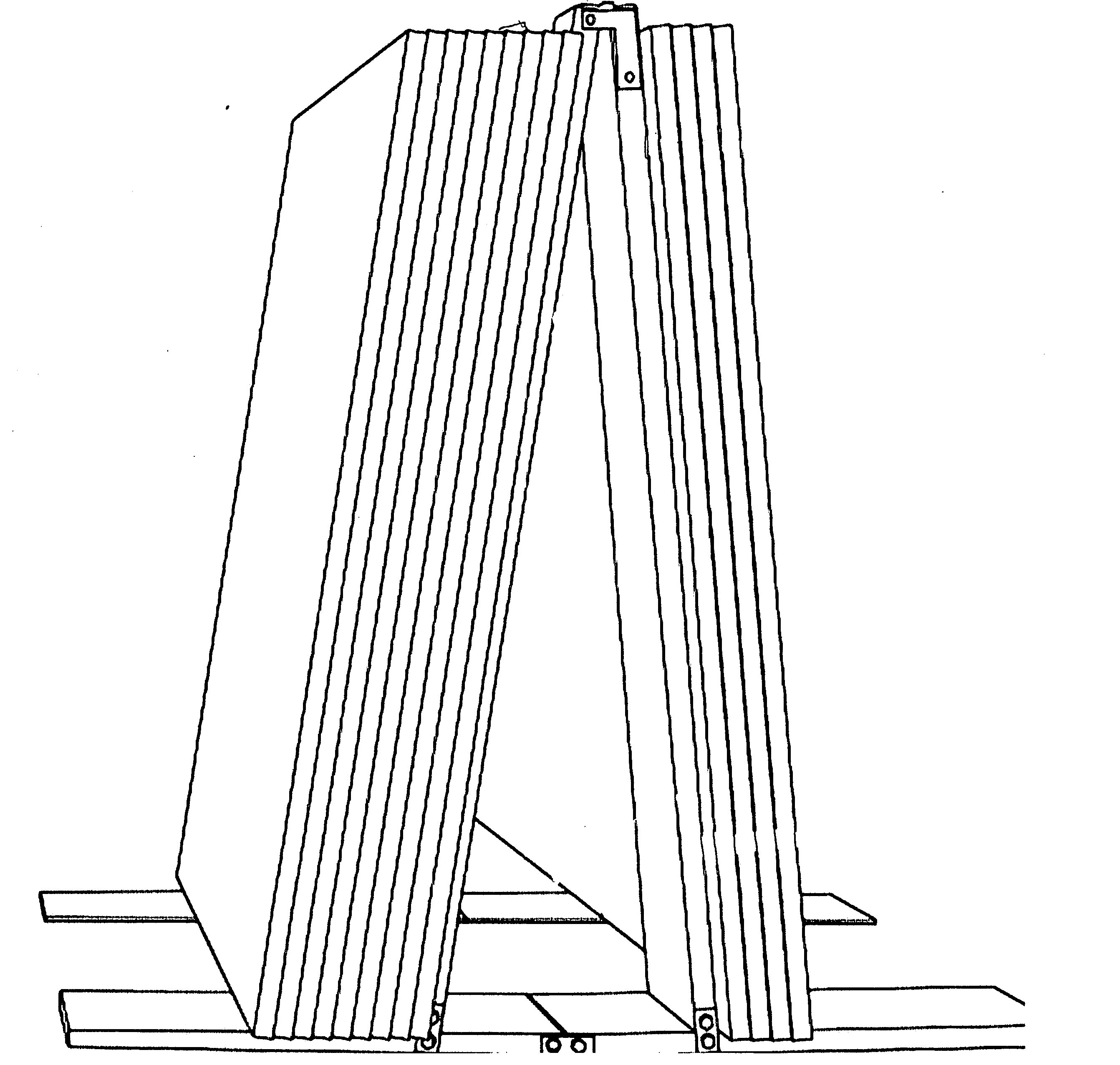

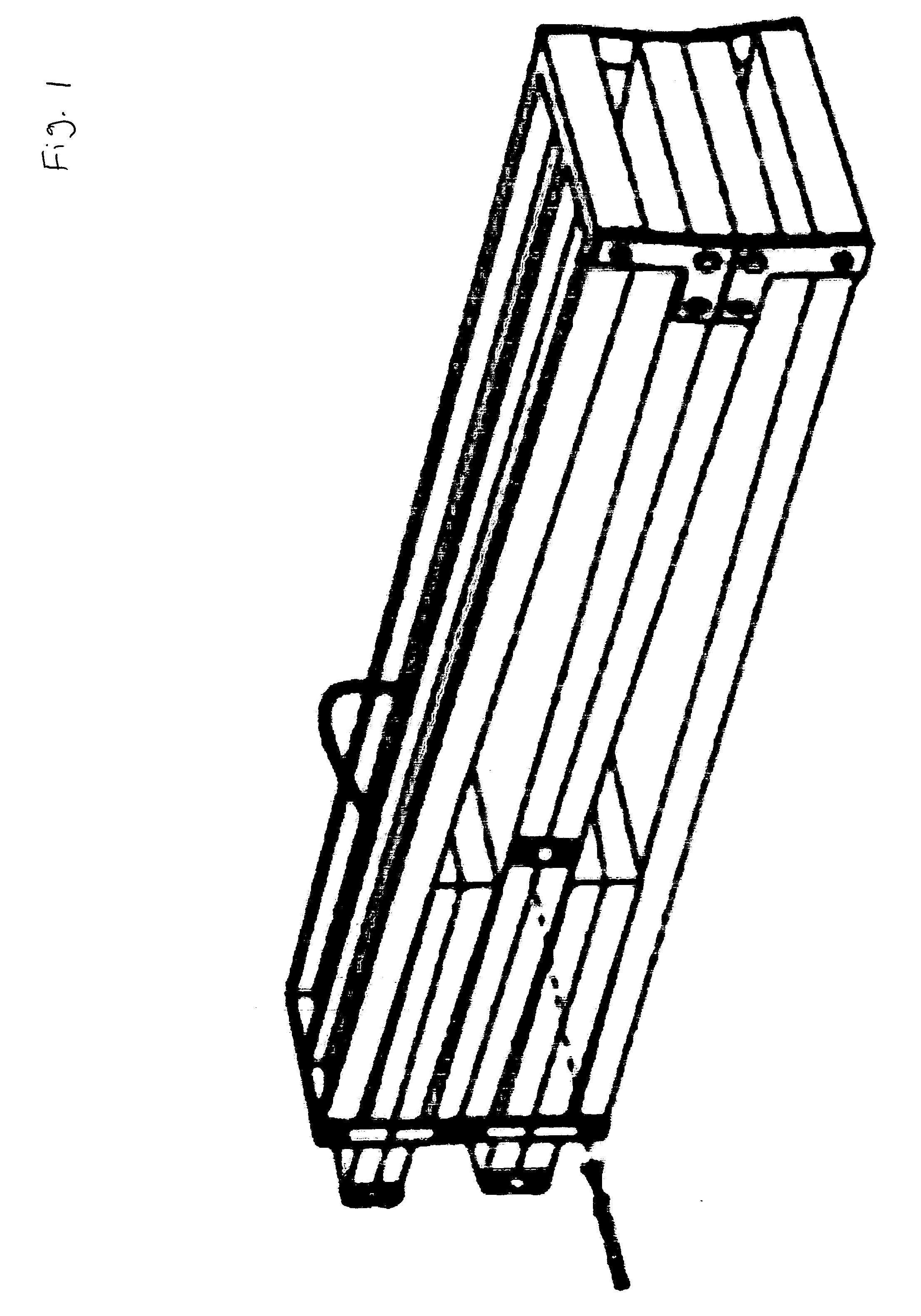

[0022]Referring to FIG. 1, there can be seen a perspective view of an embodiment of the present invention in a collapsed state. When in a collapsed state, a pin or locking member may be placed to hold the support system 10 in a collapsed state. The support system 10 of the present invention may include at set of support assemblies 20a and 20b. Each set may include a pair of support assemblies. In an embodiment, support assemblies 20a and 20b may fold using a movable joint in at least 3 places. In one embodiment support assemblies 20a and 20b the movable joints 50a, 50b, and 50c may be pivots. One of skill in the art will recognize that any suitable method of movable joints may be used.

[0023]Each support assembly may include a base 30. Base 30 may be comprised of two pieces 30a and 30b. In one embodiment, base 30 may include grooves 60 such that the base is slide resistant. In another embodiment, base 30 may include slide resistant material on its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com