Golf stand bag having folding body

a golf stand and bag body technology, applied in the field of golf stand bags, can solve the problems of limiting the reduction of the weight of the golf stand bag, the inability to fold the bag body to reduce the volume, etc., and achieve the effect of reducing logistics costs, reducing the volume of the bag body, and reducing the weight of the bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

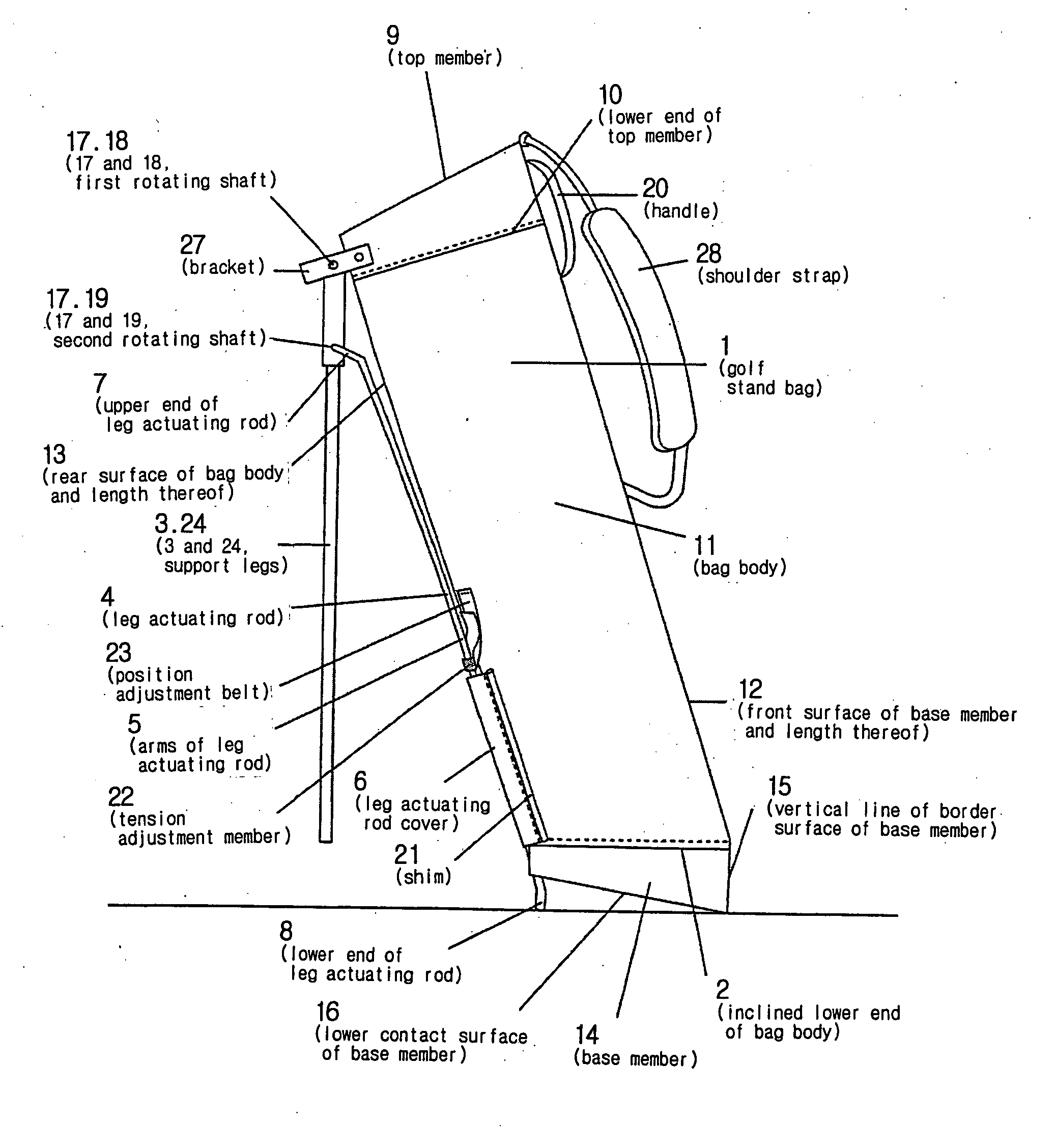

[0035]FIG. 1 is a view showing the reference numerals and names (index terms) designated to easily illustrate the construction and operation of the present invention.

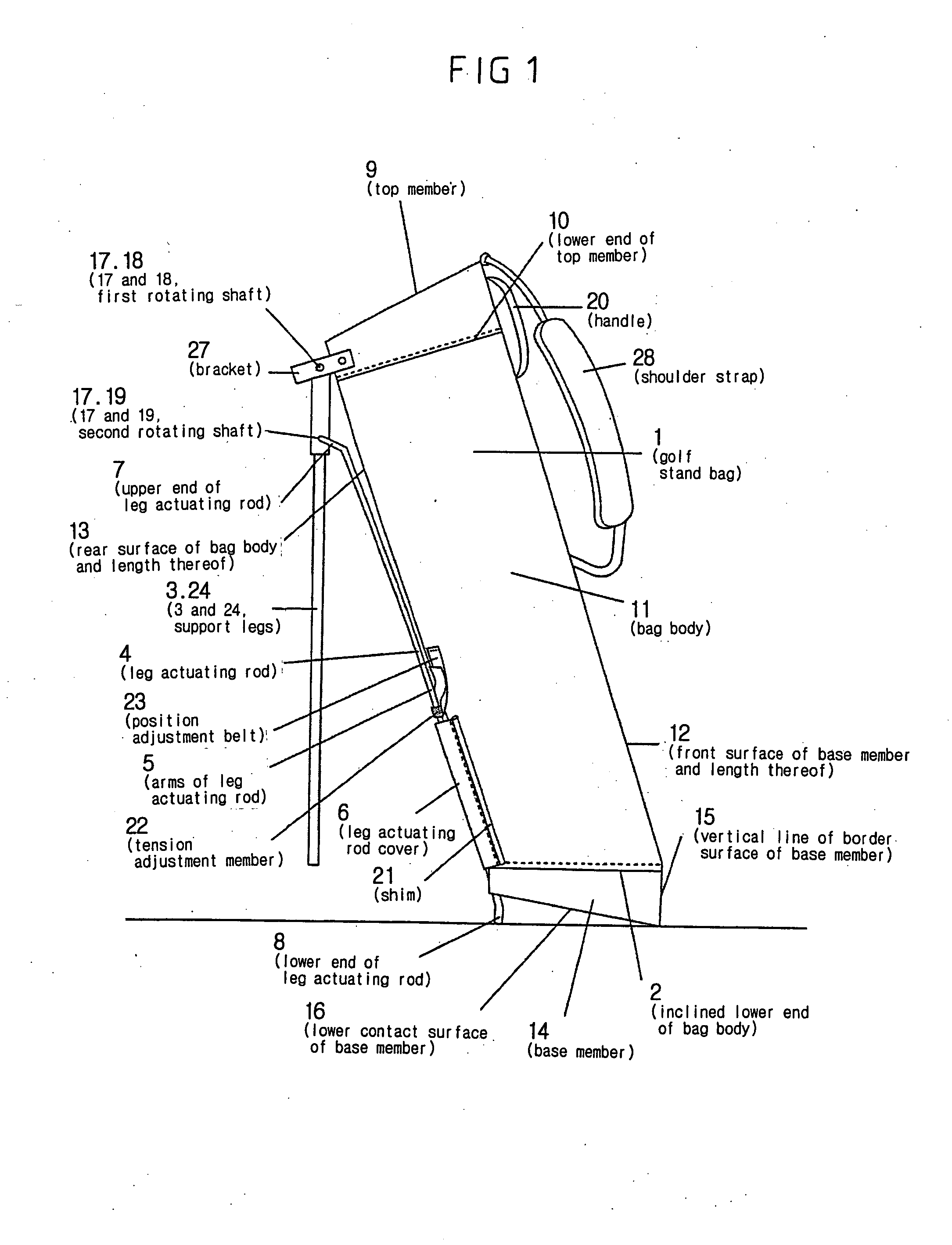

[0036]FIG. 2 is a side view showing a golf stand bag 1, which is in a state in which a user takes down the golf stand bag 1 from his / her shoulder and holds up the golf stand bag 1 using his / her hand just before the golf stand bag is placed on the ground.

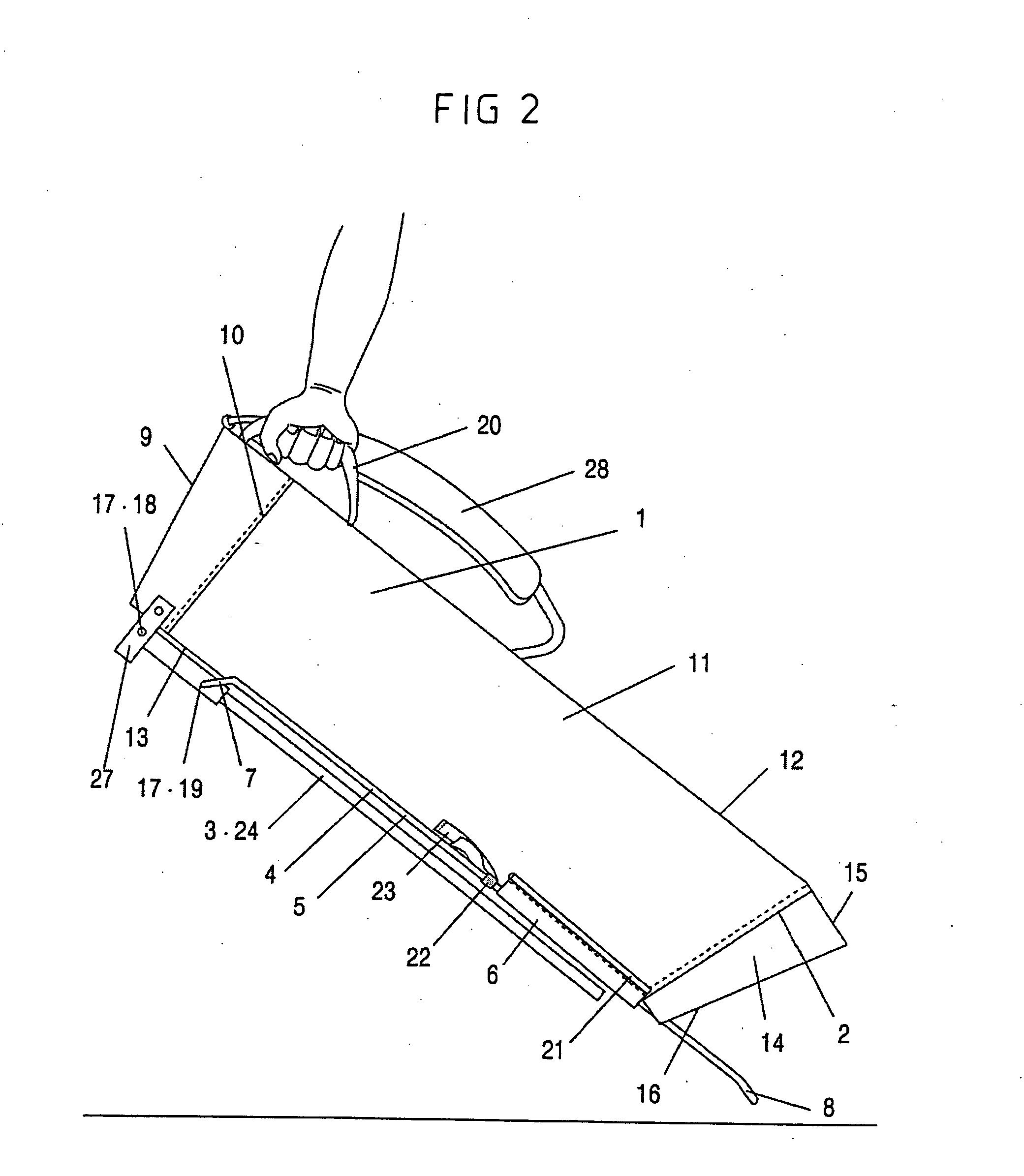

[0037]FIG. 3 is a side view showing the state in which a lower end 8 of a leg actuating rod, which extends outwards from a lower contact surface of a base member 14, is first brought into contact with the ground, when the golf stand bag 1 is placed on the ground to stand it on the ground at an incline.

[0038]FIG. 4 is a view showing an intermediate step in which a top member, which is coupled to a bracket to which support legs are rotatably supported using rotating shafts, is moved downwards by the weight of a bag body, and the leg actuating rod, which is in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com