Slot adapter for cleaning heat exchanger system and machine using same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

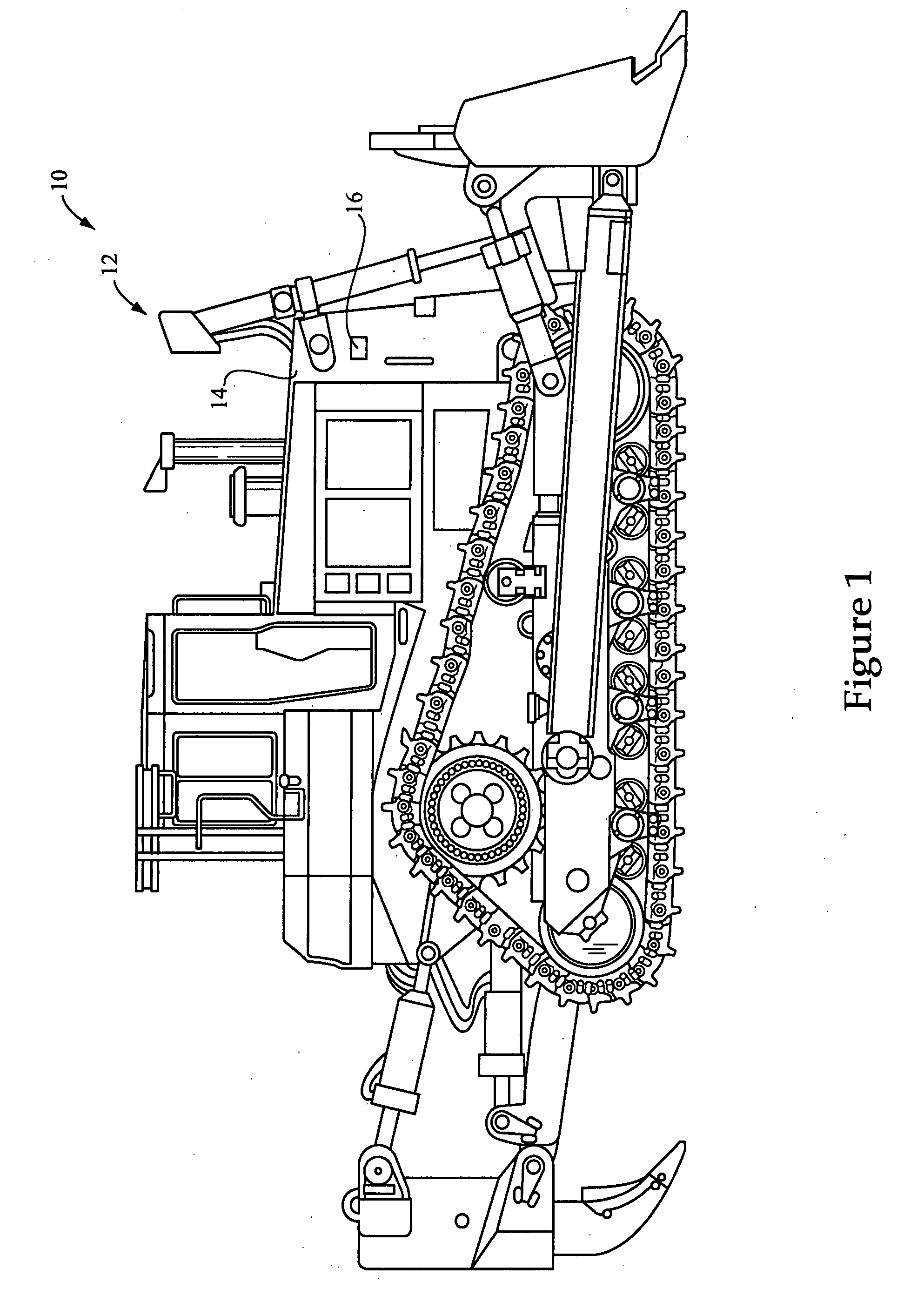

[0016]An exemplary embodiment of a machine 10 is shown generally in FIG. 1. The machine 10 may be a waste handling track type tractor, as shown, or any other vehicle having a heat exchanger system 20 (not shown). The heat exchanger system is located at a front end 12 of the machine 10 and is enclosed by a heat exchanger guard 14. The heat exchanger guard 14 includes at least one slot adapter 16, shown later in greater detail.

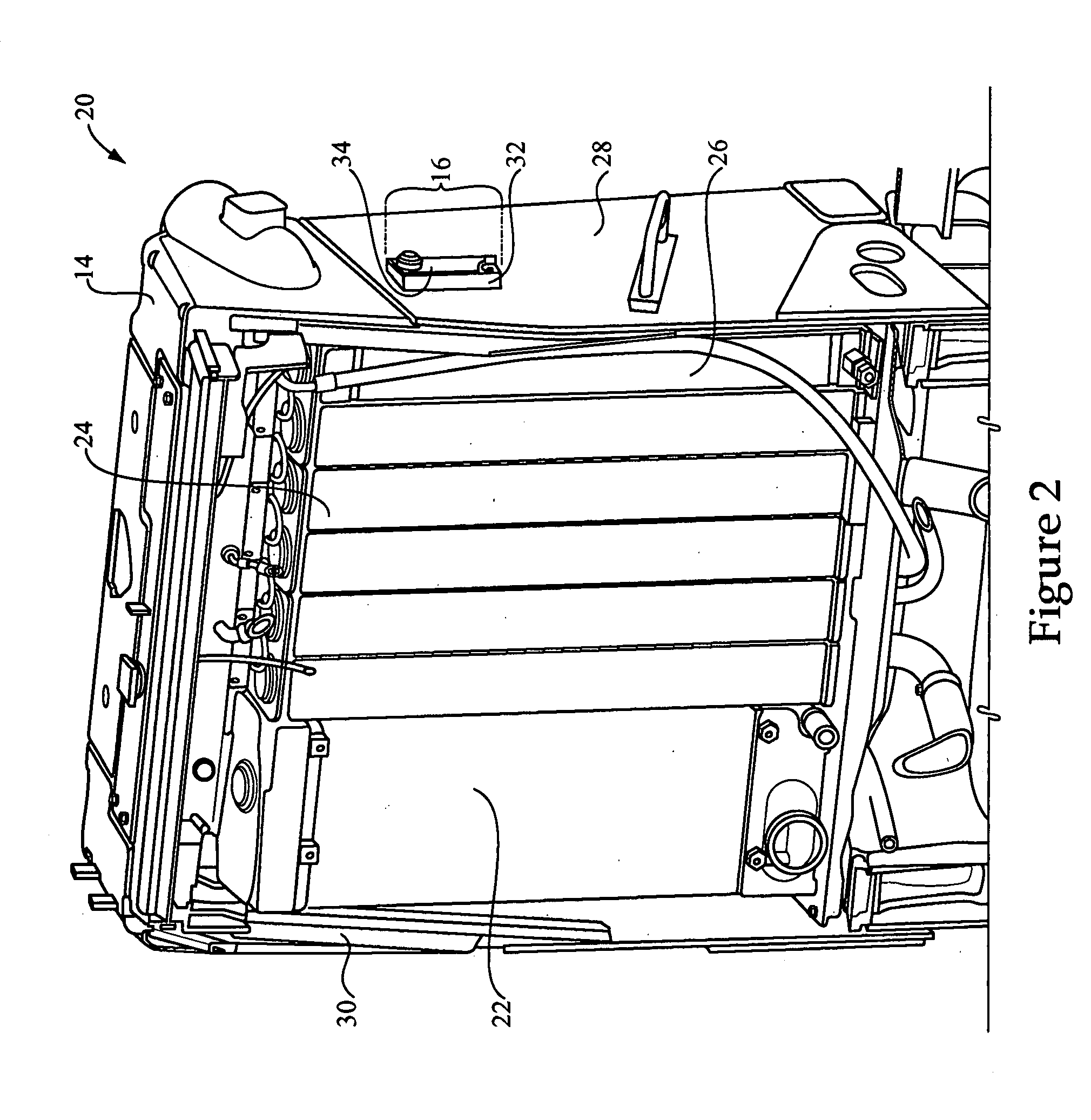

[0017]The heat exchanger system, shown generally at 20, can be seen in greater detail in FIG. 2. The heat exchanger system 20 may include an air to air aftercooler 22, a water cooling system 24, and a hydraulic oil cooler 26, all occupying a common plane and defining a core of the heat exchanger system. Although three heat exchangers are shown, those skilled in the art will appreciate that any number and type of heat exchangers may be used.

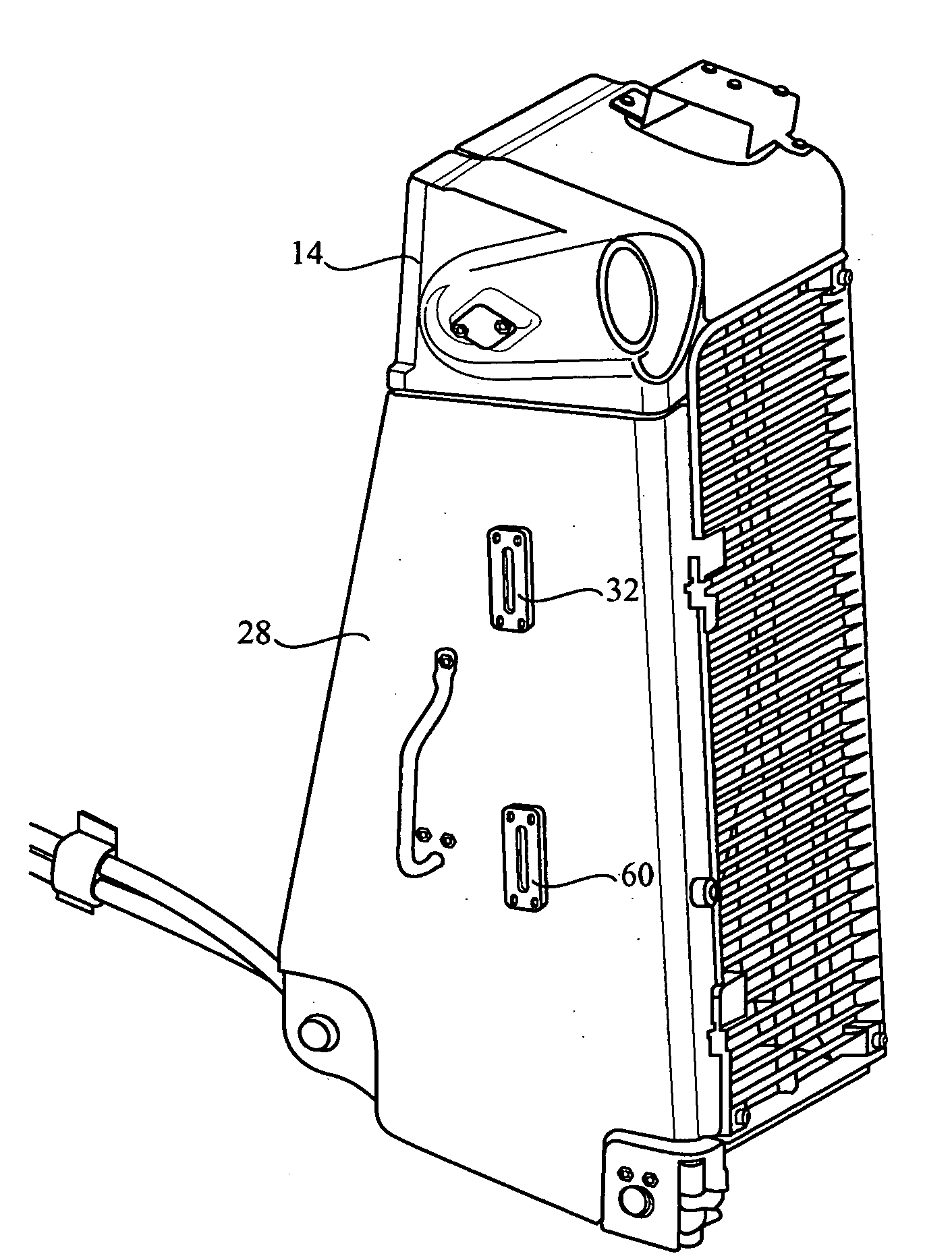

[0018]The heat exchanger system 20 is enclosed by heat exchanger guard 14. The heat exchanger guard 14 includes a first side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap