Method and apparatus for precast wall and floor block system

a floor block and prefabricated technology, applied in the field of building systems, can solve the problems of limited stability, inefficient utilization of costly crane time, and limited stability of prior art systems, and achieve the effect of immediate stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

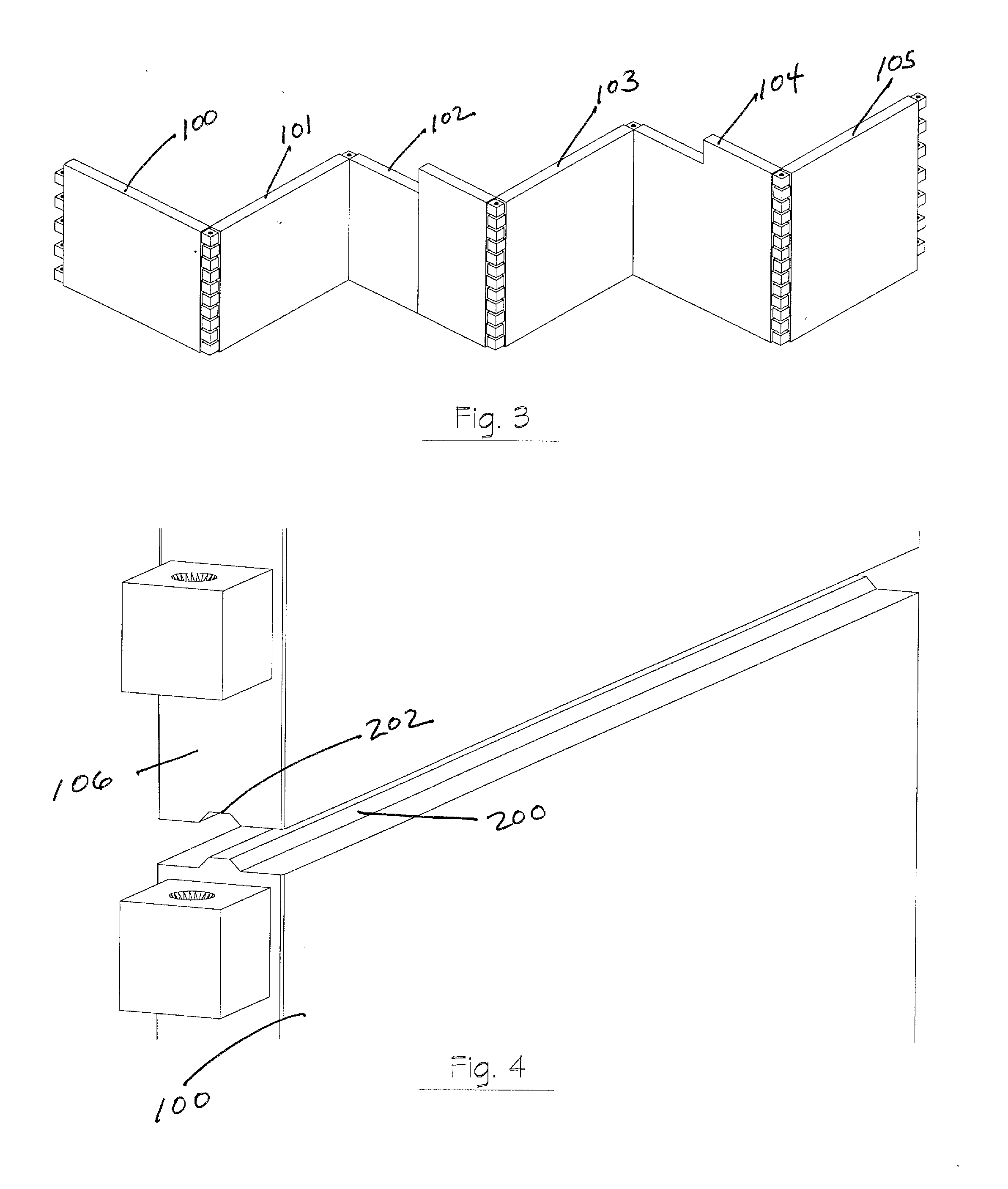

[0108]Where the offset of an architectural facade such as between blocks 630 and 631 of FIG. 38; or an interior wall such as blocks 632 and 633 is on the order of a single wall thickness, a variation of the finger joint can offer a solution. The pair of walls in FIG. 38 that point to the left each offer a finger pattern B for the forward wall, and also offer double pins and two double-width receivers to accommodate two fingers from a center wall that is inset by one wall thickness as shown in FIG. 39.

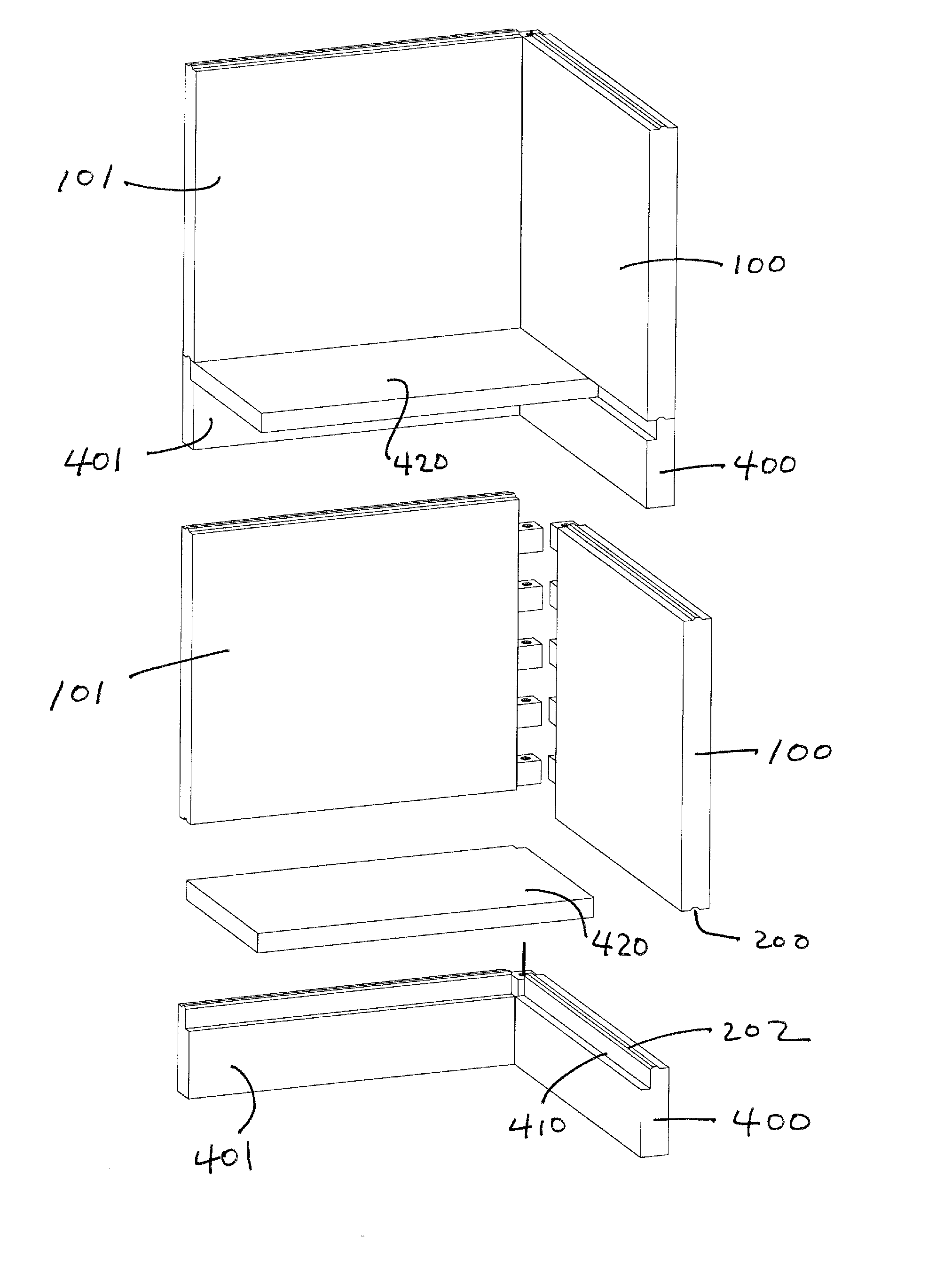

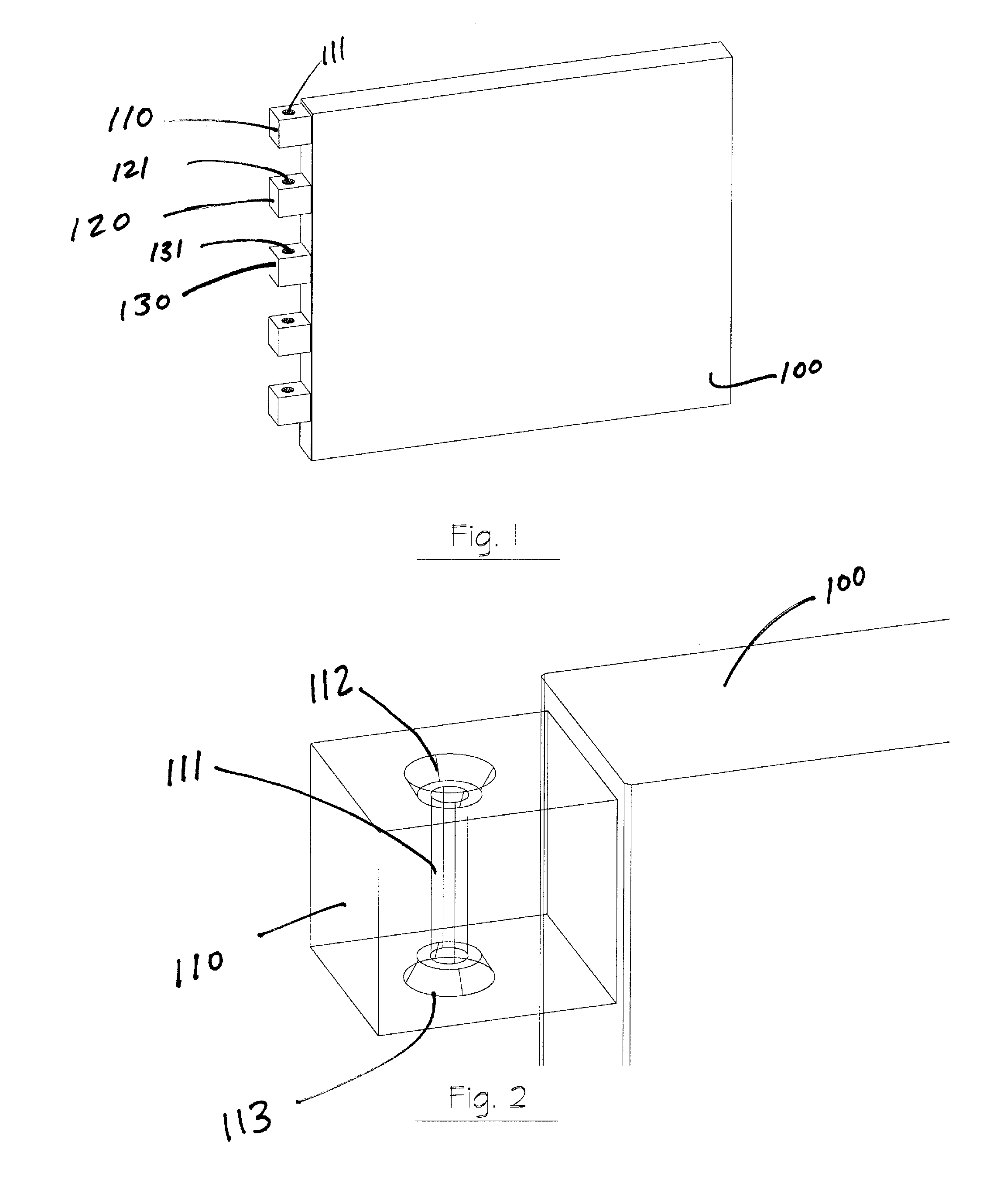

Finger Floor Block System

[0109]The ledge examples described in FIG. 11B above showed a 30 cm (12 in.) thick wall that could offer a 10 cm wide ledge 410 either side of a 10 cm keyed continuous plinth 200. This application also envisions a 20 cm (8 in.) or thinner wall that can carry floor on one or both sides and stack to build multi-story construction. The thinner walls feature full-width bearing ledges at interior bearings and half-width ledges at perimeter bearings, and they show a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com