Two-finger four-pin automatic picking and placing device for plug seedling transplanting

An automatic technology for plug seedlings, applied in the direction of transplanting machinery, planting methods, applications, etc., can solve the problems of poor flexibility and unavoidable damage to seedlings, and achieve the effects of simple structure, reduced damage to seedlings, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

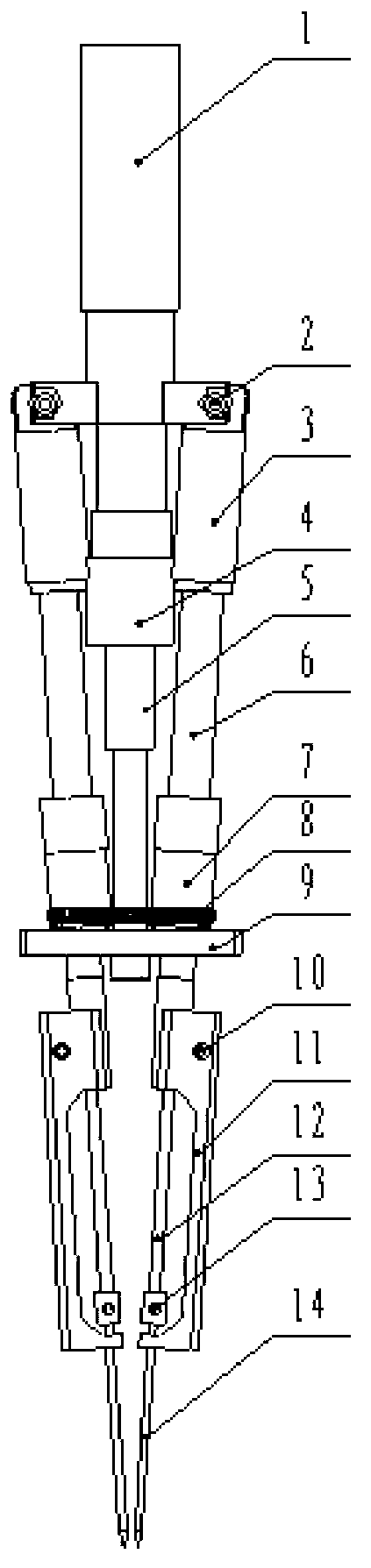

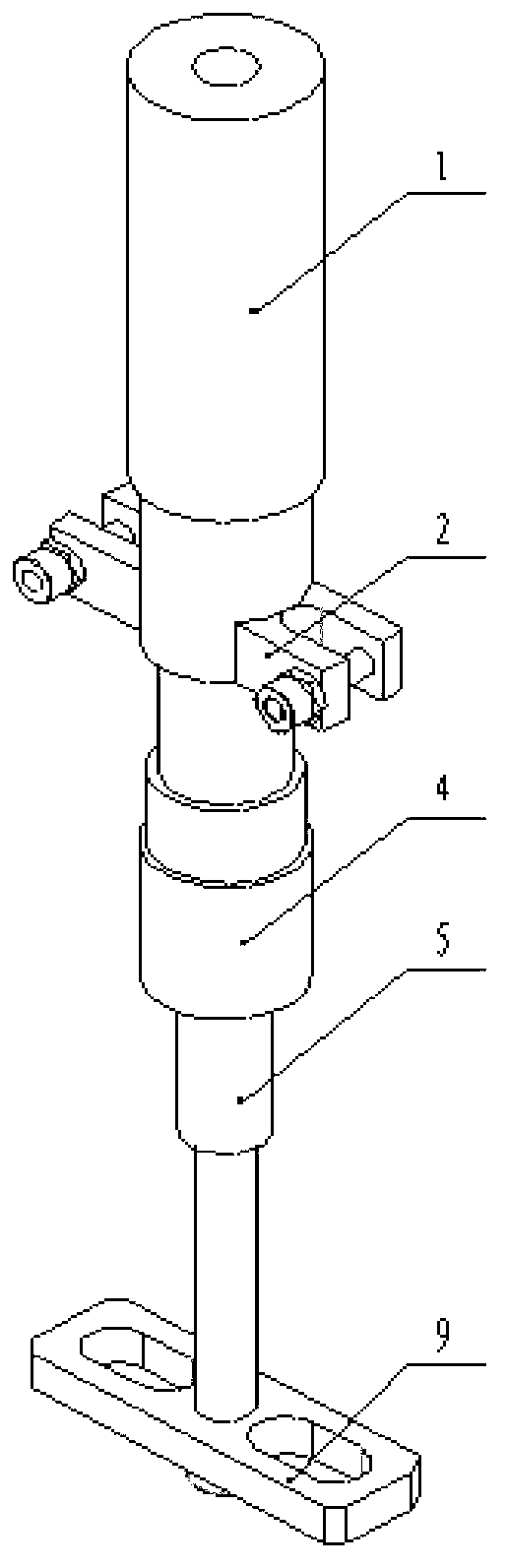

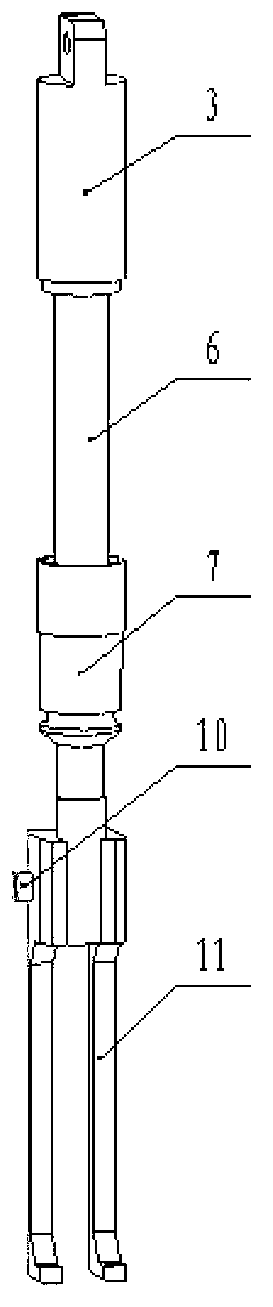

[0016] like figure 1 As shown, the overall structure of the present invention is composed of a mechanical cantilever sleeve, a mechanical finger skeleton, a mechanical finger joint, a rubber finger, a miniature cylinder, a mechanical limit block, a mechanical finger sleeve, a gripping needle, a spring, and the like. The specific layout of each kinematic pair and parts is as follows: the mechanical cantilever sleeve 1 is installed on the seedling picking frame, and its installation position can be adjusted by rotation. The mechanical finger skeleton 2 is configured on the mechanical cantilever sleeve 1 for hanging two mechanical Finger joints 3, each mechanical finger joint 3 is connected with the mechanical finger frame 2 through a rotating pair, so that the mechanical finger joint 2 can flexibly swing, the rubber finger 4 is fixedly connected to the mechanical finger frame 2, and the airbag of the rubber finger 4 bears against the two A mechanical finger joint 3, each mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com