Bamboo wood original state regular polygon recombined material and method for producing the same

A manufacturing method and bamboo technology, applied in the field of materials, can solve the problems of poor surface quality, damage to the macroscopic structure of natural bamboo, and irreplaceable problems, so as to improve the ability of being close to nature, save forest resources, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

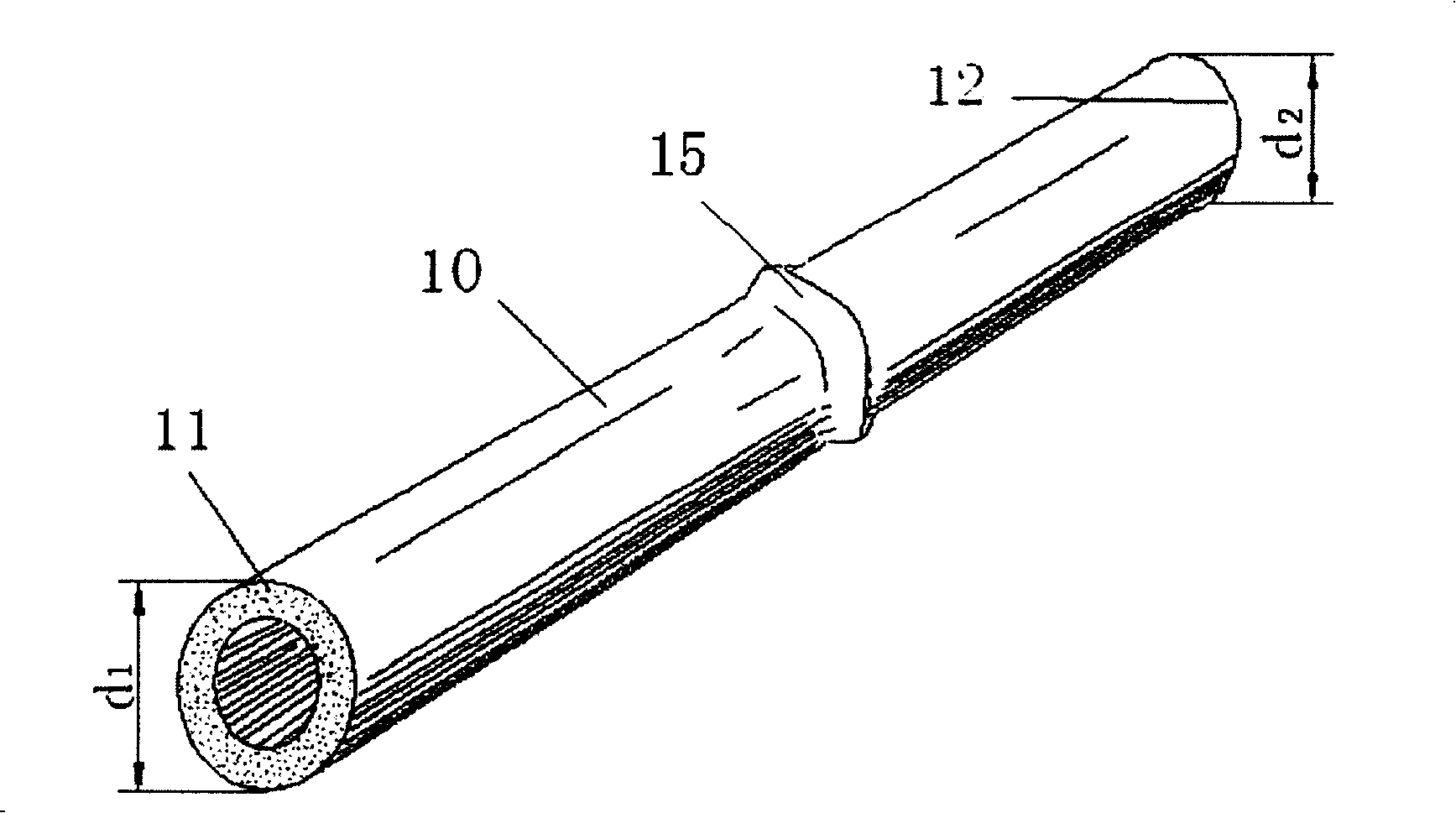

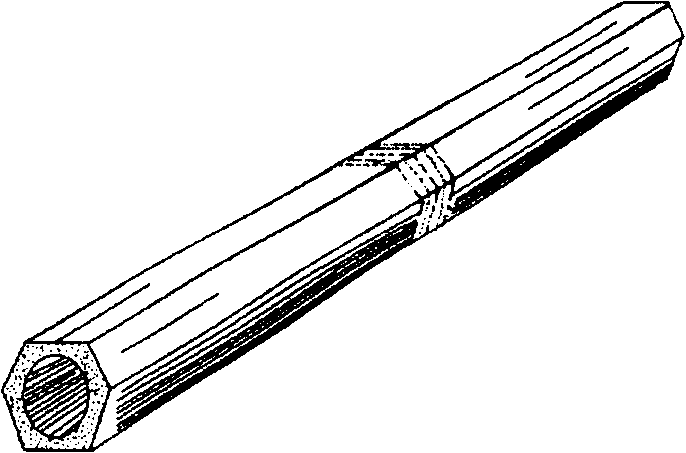

[0054] The bamboo original state multi-party recombination material that present embodiment provides is made up of several outer surfaces of regular hexagonal bamboo units 10a, and part of the side planes of bamboo units 10a or all side planes 13 are coated with an adhesive layer. The adhesive layer makes the sides of several bamboo units 10a stick together to achieve any expansion in the lateral direction; one or both ends of the regular polygonal bamboo units 10a are mortised and mortised to other bamboo units so that they can be extended arbitrarily in the longitudinal direction.

[0055] The average DBH error of several bamboo units 10a is within ±15mm, the regular hexagonal bamboo units with uniform outer surface are longitudinally mortised, some or all of the side planes 13 are coated with an adhesive layer, heated or cold Bonding to form the original hexagonal recombined bamboo material of any length.

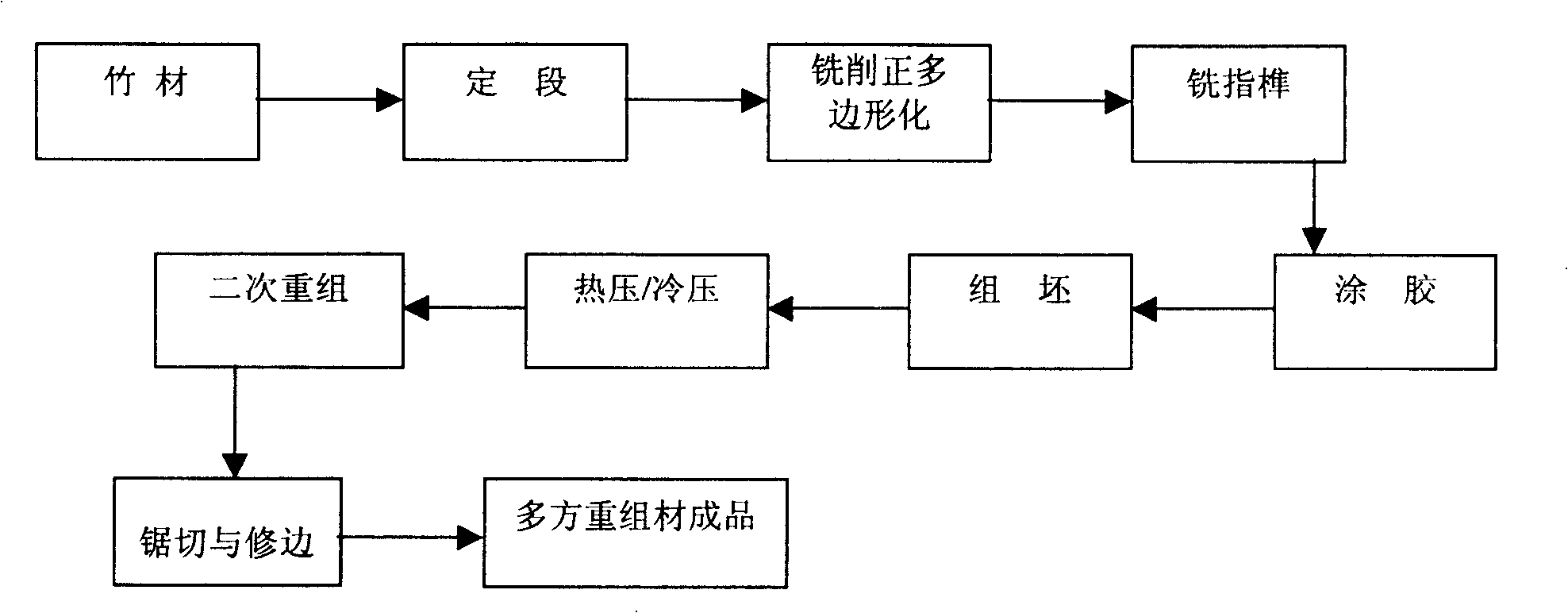

[0056] The process flow of the processing method is as figure 1 sh...

Embodiment 2

[0069] refer to Figure 1 to Figure 9 As shown, select bamboo with the same diameter at breast height, and determine the section according to the fixed value of the diameter difference between the large and small ends. After face milling, the outer surface of the bamboo is processed into a regular hexagonal bamboo unit with the same specifications. Finger milling. The cross-sections are arranged side by side in a honeycomb shape, longitudinally tenoned into arbitrary lengths, and processed into bamboo original multi-party recombined materials. Specific steps are as follows:

[0070] (1) Same as step (1) of embodiment 1.

[0071] (2) Same as step (2) of embodiment 1.

[0072] (3) Same as step (3) of embodiment 1.

[0073] (4) Apply glue to several glued surfaces and tenon joint surfaces of regular hexagonalized bamboo units, arrange them side by side in a honeycomb shape with their cross sections; The finger joints are staggered, and different cross-section specifications ...

Embodiment 3

[0078] First, select bamboo with a similar diameter for sawing and cutting into sections. In this embodiment, the bamboos with equivalent diameters include two groups of bamboo units of two specifications, one is a larger bamboo section, and the other is a smaller bamboo section. Paragraphs are defined in principle.

[0079] Then, the bamboo unit 201 of the regular octagonalization will be milled into the straight-down larger bamboo section, and the bamboo unit 202 of the regular quadrilateralization is milled into the other for the lesser bamboo section of diameter, and the side of the cross-section of the bamboo unit 202 of the quadrilateralization The length is correspondingly equal to the side length of the cross-section of the regular octagonal bamboo unit 201 . Two kinds of bamboo units are respectively milled out the finger-shaped tenon at one end or both ends, and the method described in the step (4) of the previous embodiment 1 is carried out for longitudinal reorgan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com