Cooling device

a cooling device and cooling technology, applied in lighting and heating apparatus, ventilation systems, heating types, etc., can solve the problems of deteriorating the efficiency and lifespan of cooling fans, affecting the operation stability of cooling fans, and consuming partial electrical energy, so as to improve the heat dissipation area and heat dissipation performance of the circuit board, and facilitate fast heat dissipation. , good cooling mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]To make the object, characteristic and performance of the present invention more self-explanatory, two preferred embodiments of the present invention are provided as follows together with the illustration of the figures.

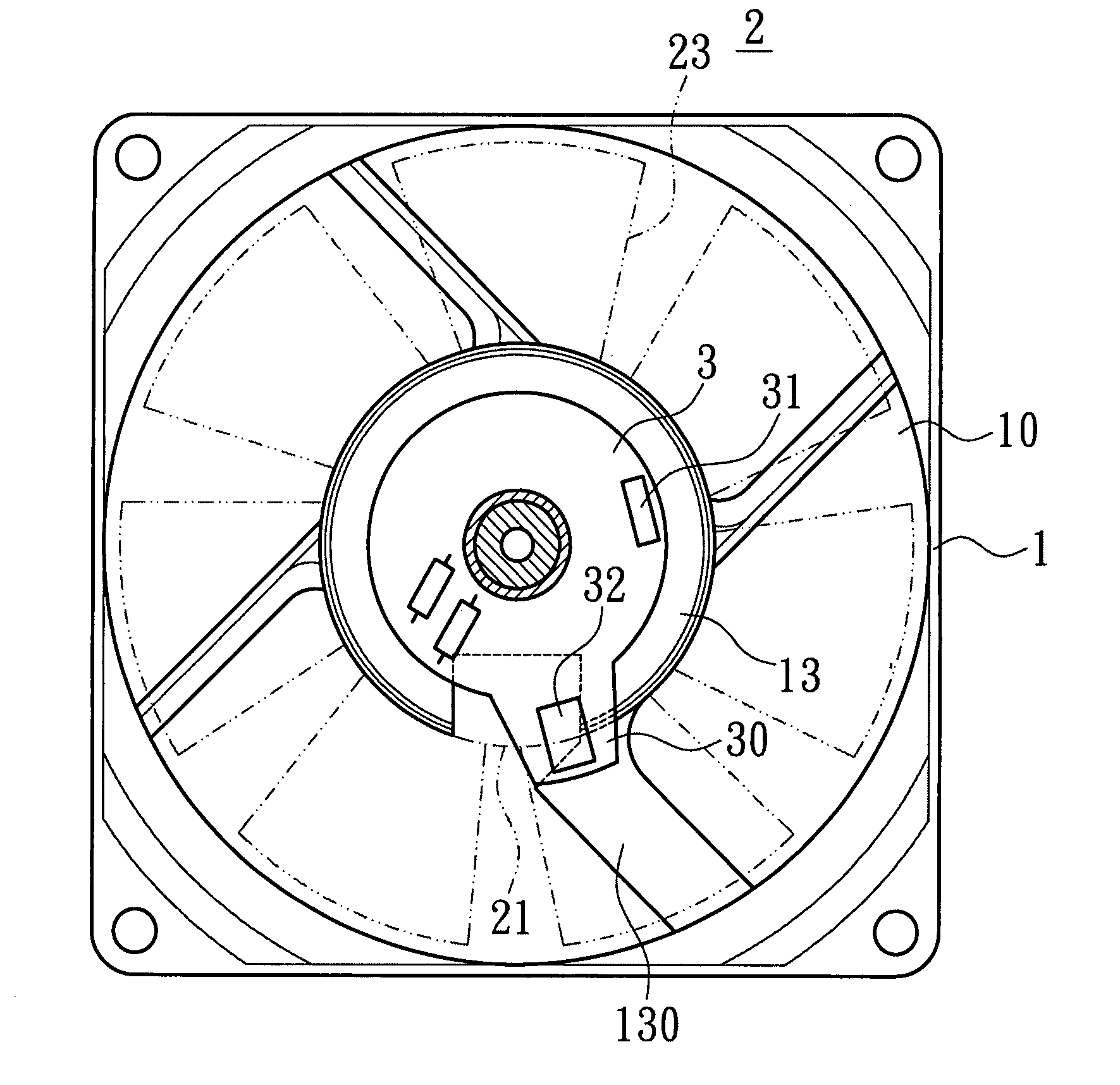

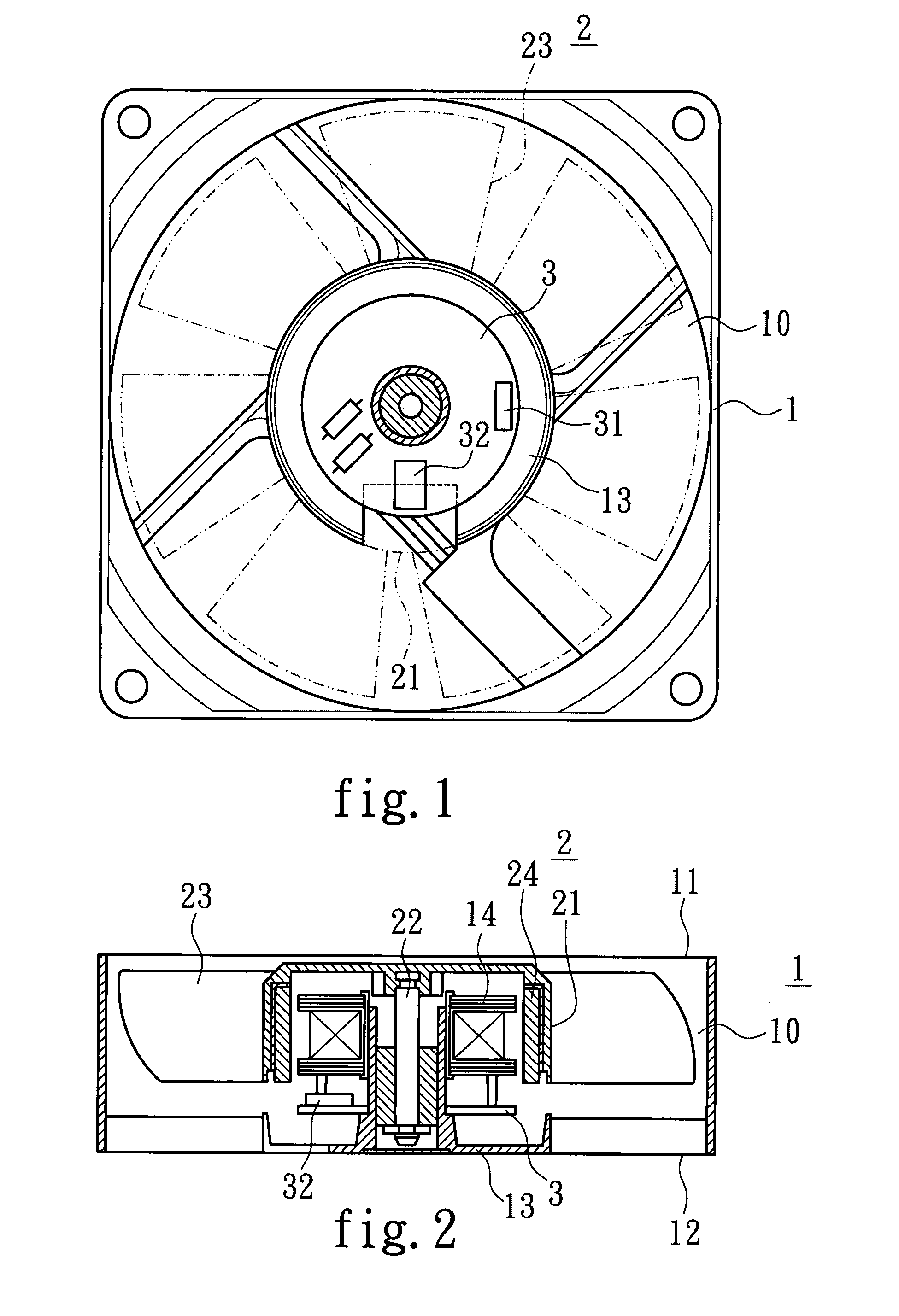

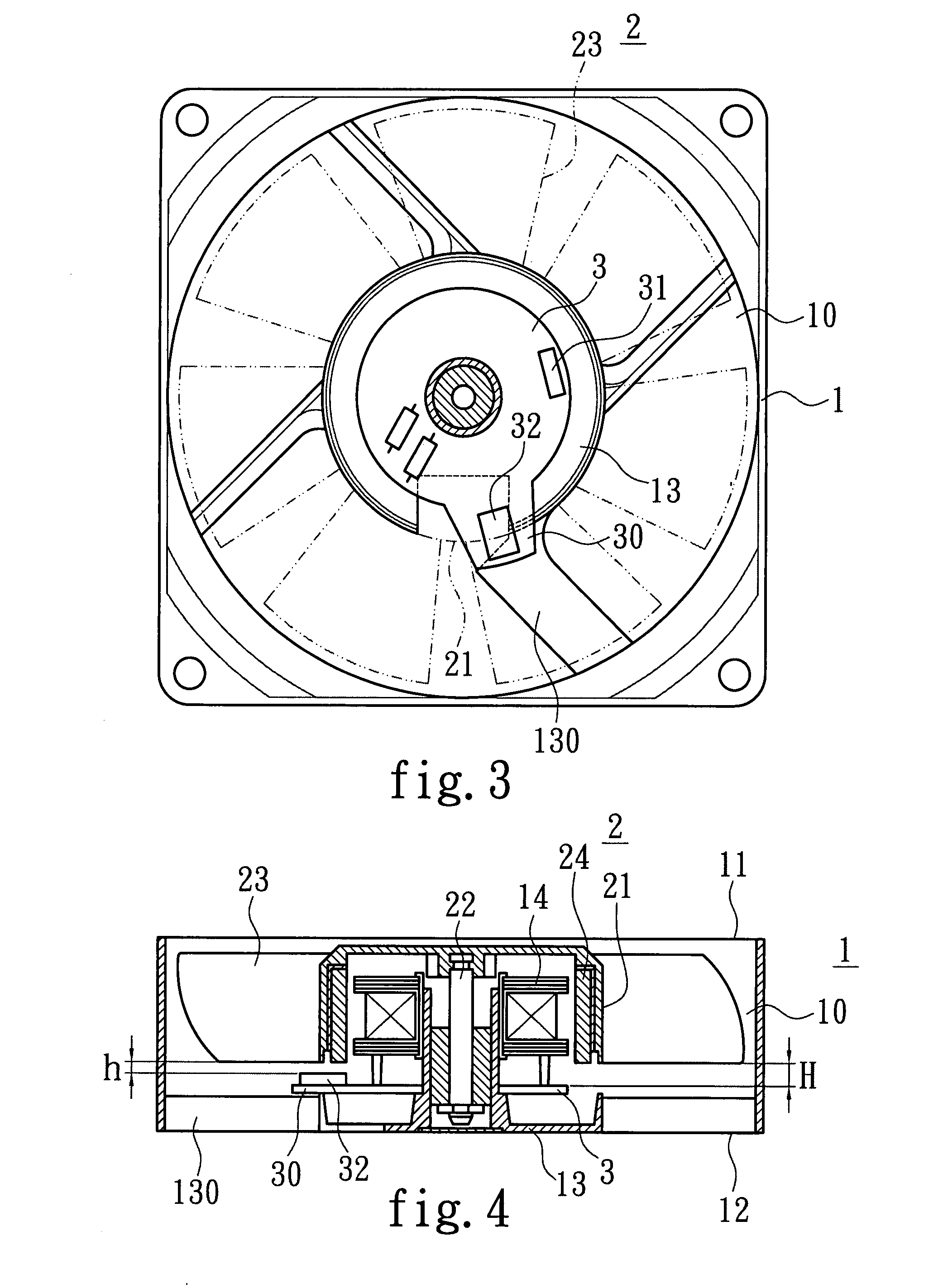

[0022]As shown in FIG. 5, a first preferred embodiment of the present invention includes a housing 1, an impeller 2 and a circuit board 3.

[0023]Together with the reference to FIG. 6 and FIG. 7, the housing has an air flow channel 10, an air inlet 11, an air outlet 12, a base 13 and a stator set 14. The air flow channel 10 can accommodate an impeller 2, the air inlet 11 and the air outlet are located on both sides of the air flow channel 10 such that air flow is inputted to the air inlet 11 and outputted from the air outlet 12, the base 13 is selectively disposed beside the air outlet 12 or the air inlet 11 depending on the requirement of actual heat-dissipation occasion and has a plurality of ribs 130, a shaft tube 131 and at least a cable gap 133, in which eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com