Fluid flow connector permitting forceful lateral separation

a technology of flow connector and lateral separation, which is applied in the direction of hose connection, medical devices, other medical devices, etc., can solve the problems of blood loss and great inconvenien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

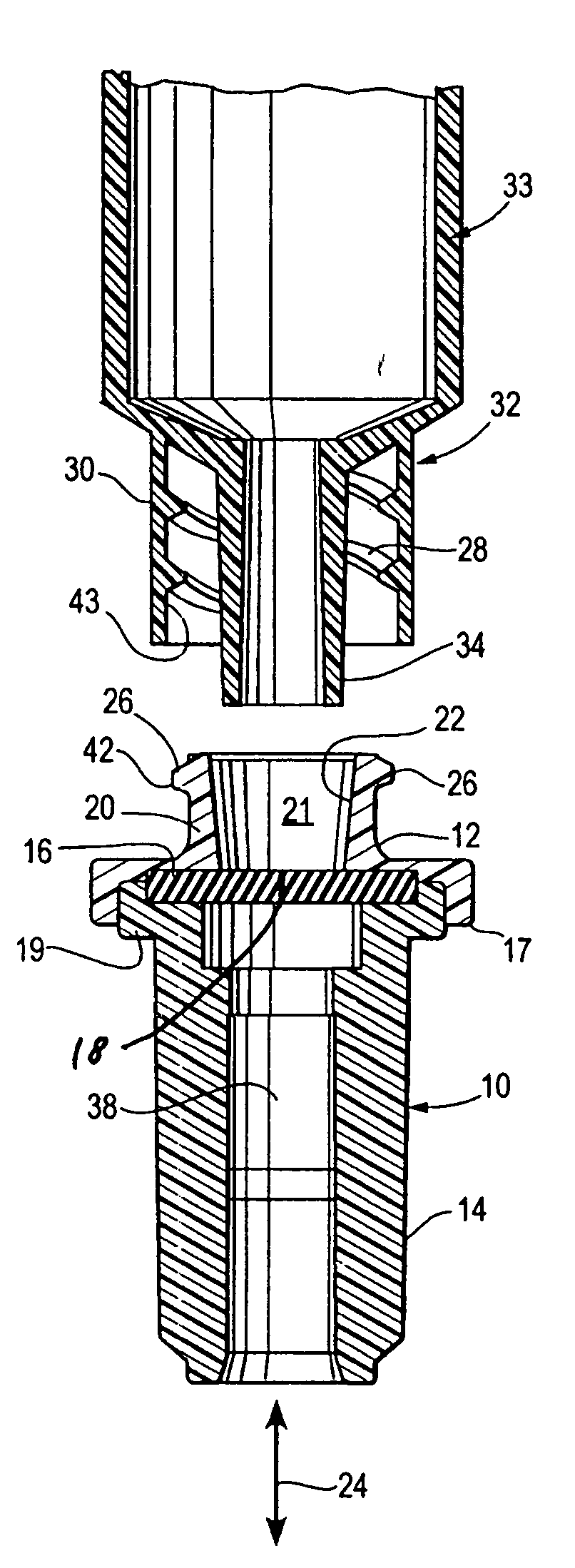

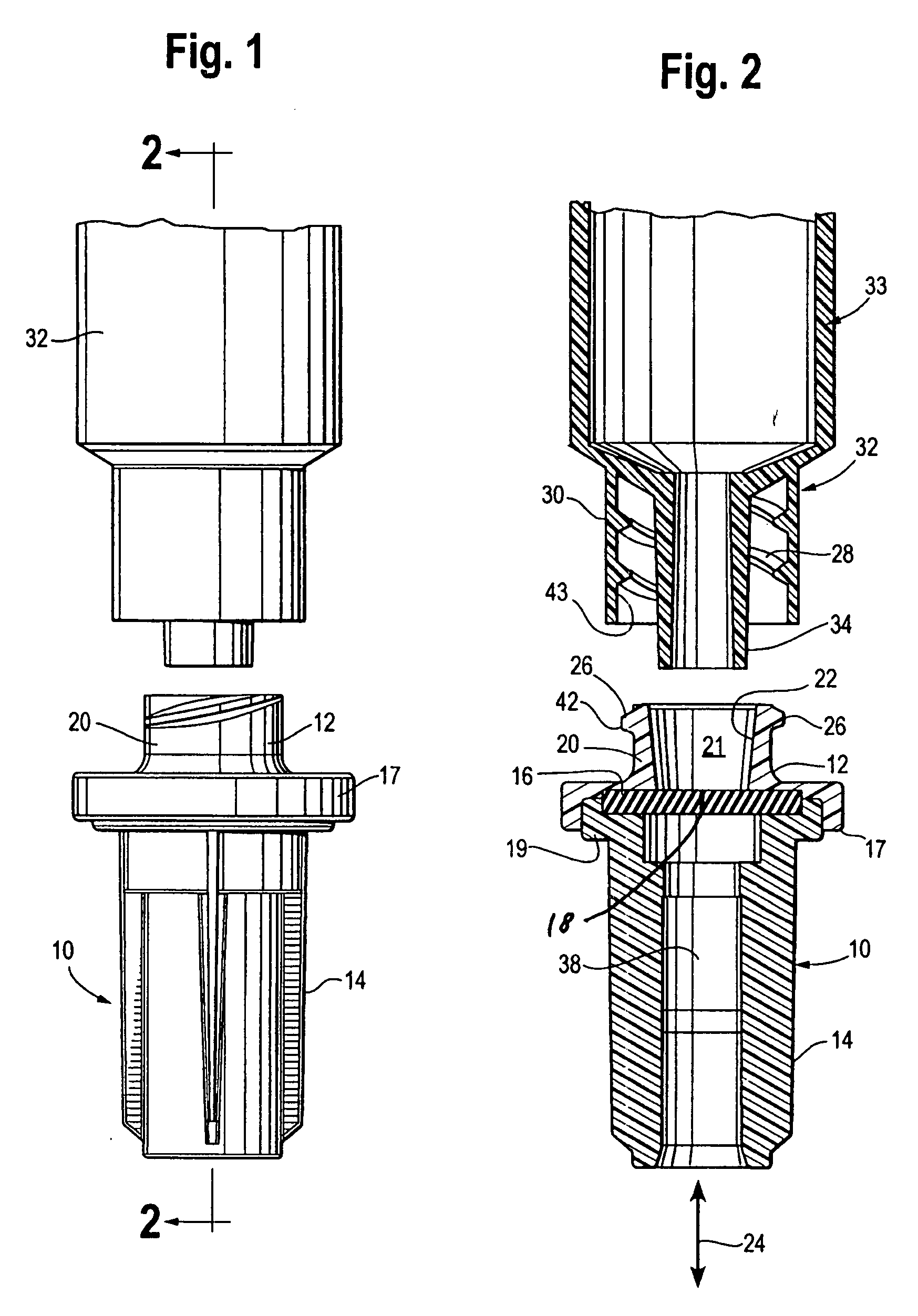

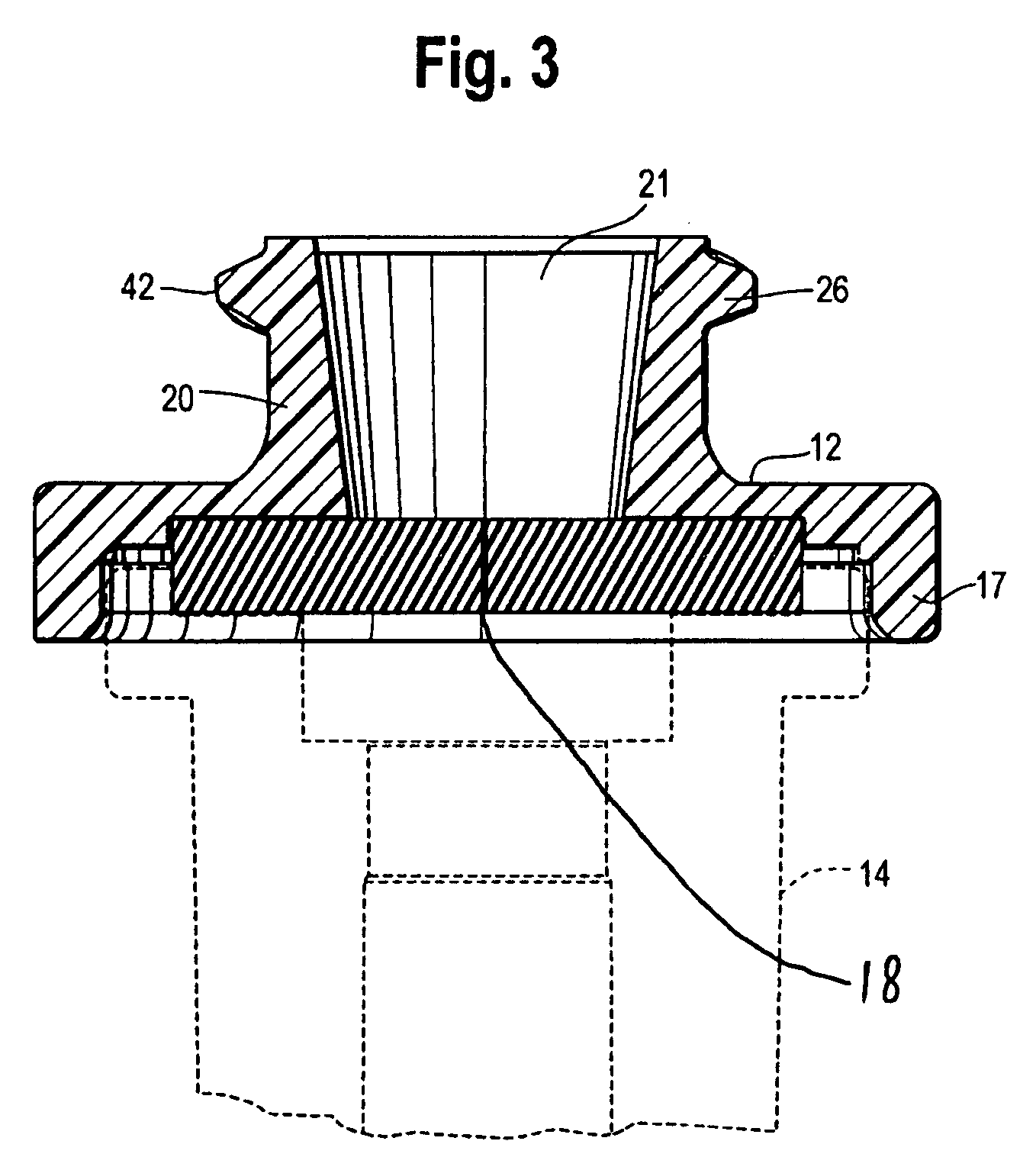

[0006]By this invention, a first fluid flow connector comprises: a connector body which carries a first connector tube having a lumen for receiving a second connector tube of a second connector when said connectors are joined. The first connector tube may have a lumen and a lumen wall, for example of angled cone shape, in at least a major outer portion thereof, to the longitudinal axis of the first connector. The first connector tube carries a plurality of circumferentially spaced, outwardly extending lugs, to engage inwardly extending threads or lugs of the second connector tube when connected.

[0007]The first fluid flow connector may be made of a plastic which has a dimensions (especially thickness) and a flexural modulus that is low enough to allow deformation, permitting a connected, engaging second connector to pop loose from connection with the fluid flow connector when laterally struck, rather than breaking the first fluid flow connector.

[0008]The lugs of the first connector t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com