Method and Device for Production of Nanofibres From the Polymeric Solution Through Electrostatic Spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment

OF EMBODIMENT

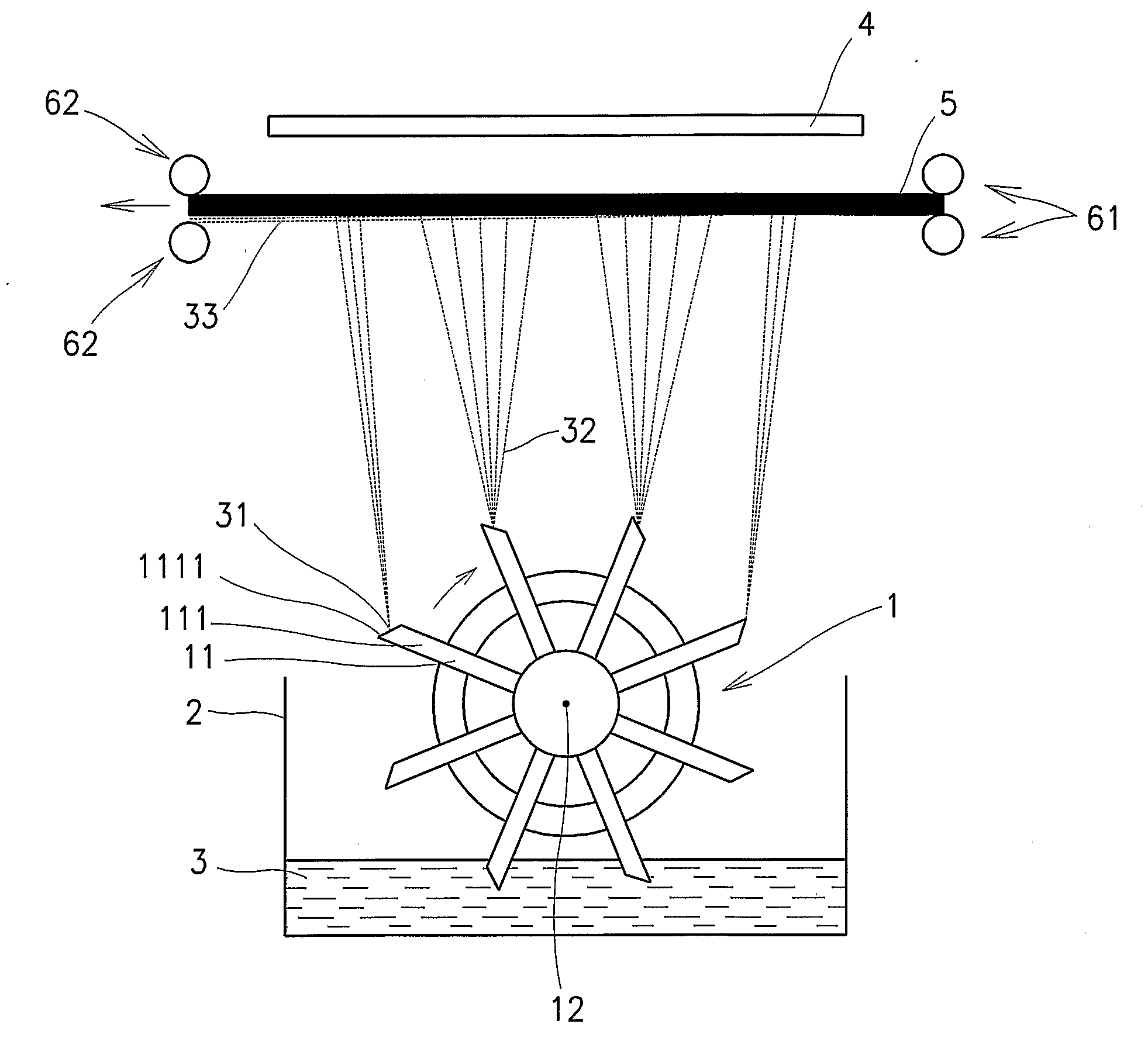

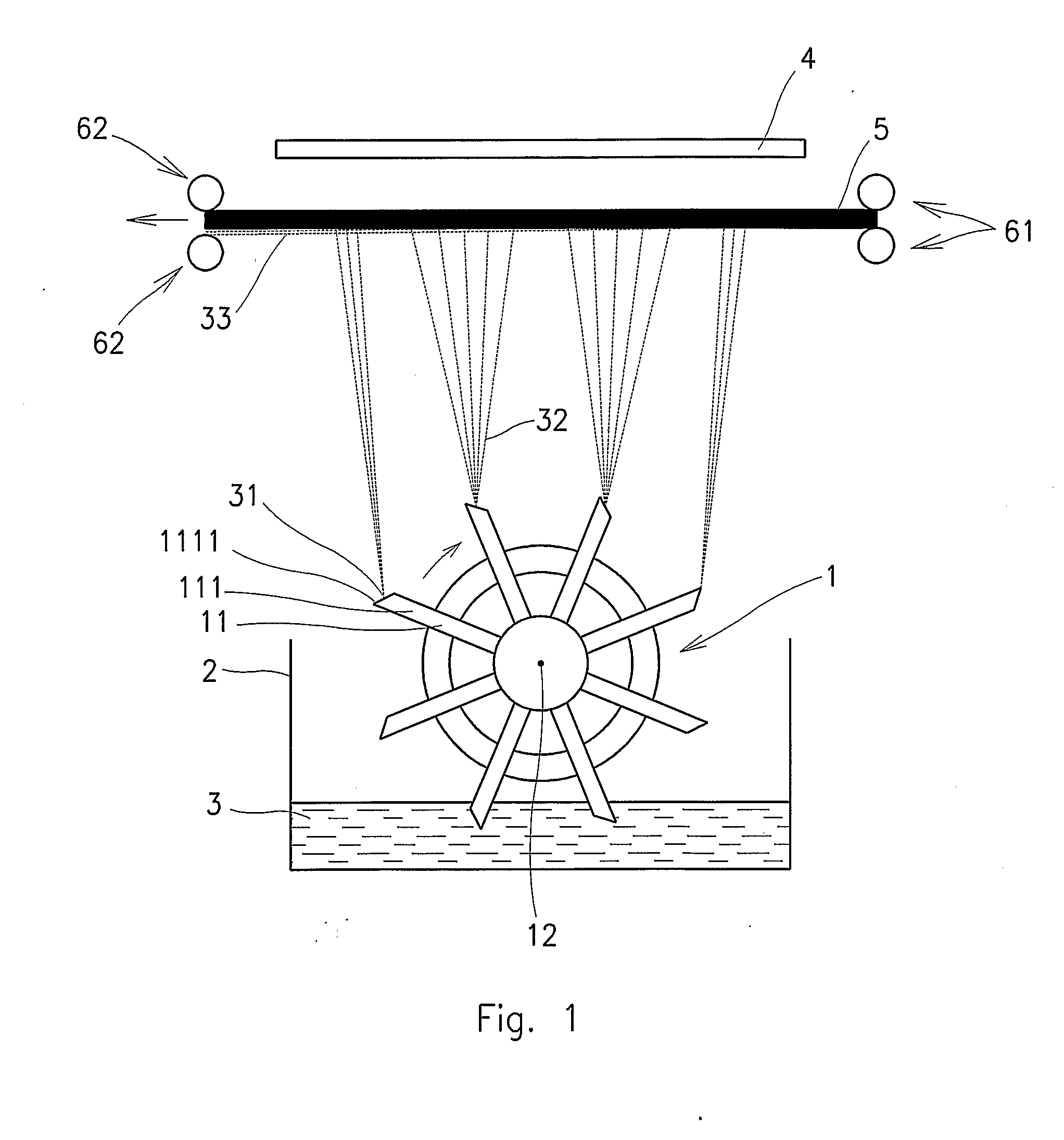

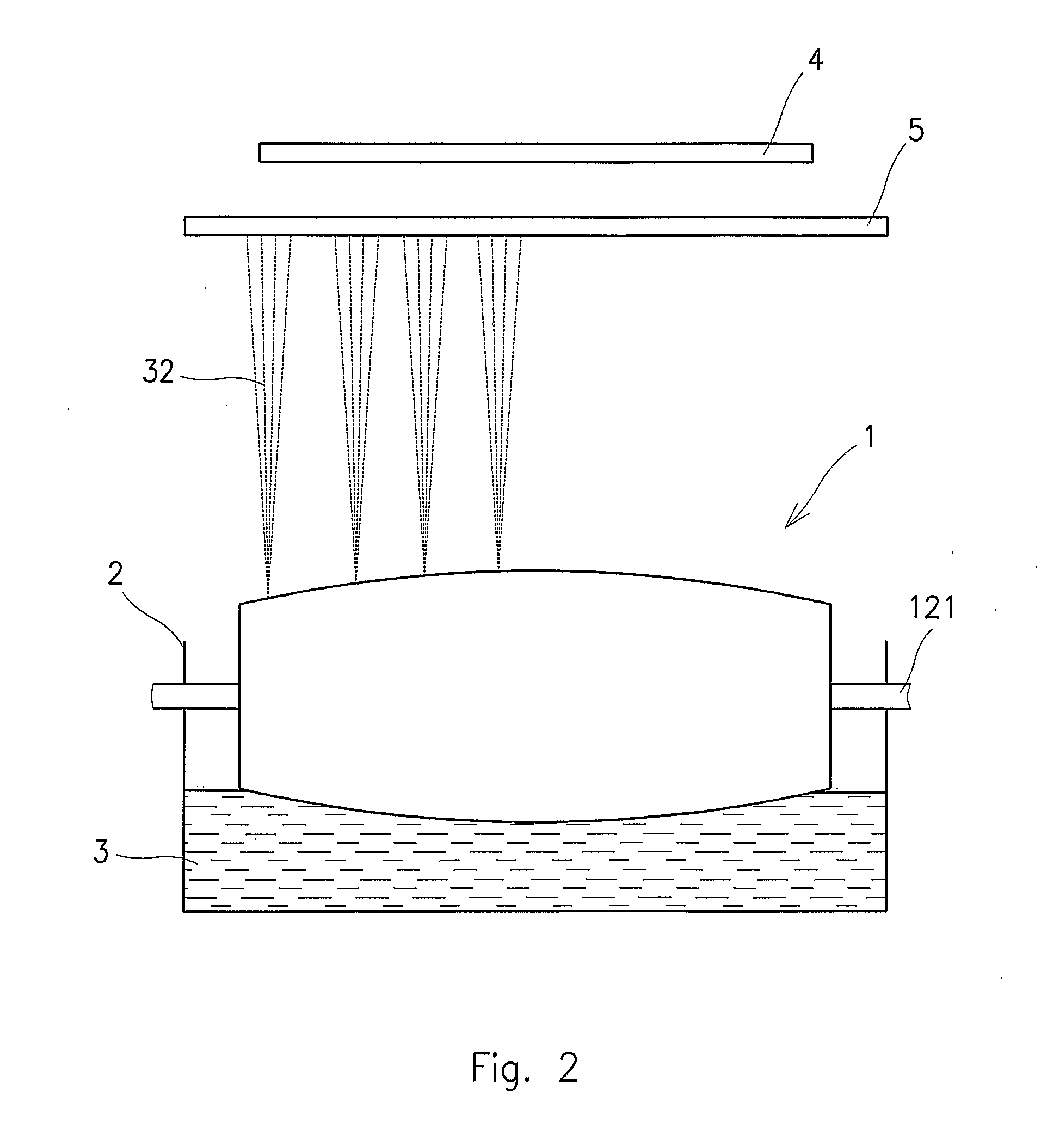

[0048]A device for production of nanofibres from the polymeric solution through electrostatic spinning illustrated in the FIG. 1, 3 to 7 contains the spinning electrode 1 created by lamellas 11 arranged radial and longitudinally around the axis 12, which is by a known not illustrated manner pivoted in the body of the equipment. The individual lamellas 11 of the spinning electrode 1 or the whole spinning electrode 1 are in a known not illustrated manner connected with a not illustrated source of a high voltage or grounded. The lamellas 11 are spread along the whole length of the spinning electrode 1 and they are evenly distributed around its perimeter. In the illustrated execution the axis 12 of the spinning electrode is created by a shaft 121, which is by a known not illustrated manner coupled with a drive ensuring its rotation movement.

[0049]Under the spinning electrode 1 there is positioned a reservoir 2 with polymeric solution 3. Lamellas 11 in the lower section of t...

example 1

[0073]The spinning lamellar electrode according to FIG. 3 rotates in the reservoir of polyamide solution PA 612 (conc. 20% wt., Mr 2800 g / mol) in an acid. Immersion of the lamella is such that only spots of tips are dipped. The electrode rotates in a retrograde manner towards the movement of the non-conducting spunbond base textile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com