Electrostatic spinning method of free liquid-surface multi-nozzle arrangement

An electrospinning and multi-nozzle technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of unstable state of filament, electric field disturbance, poor spinning effect, etc., and achieve spinning effect Good, improve production efficiency, and stabilize the silk output state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

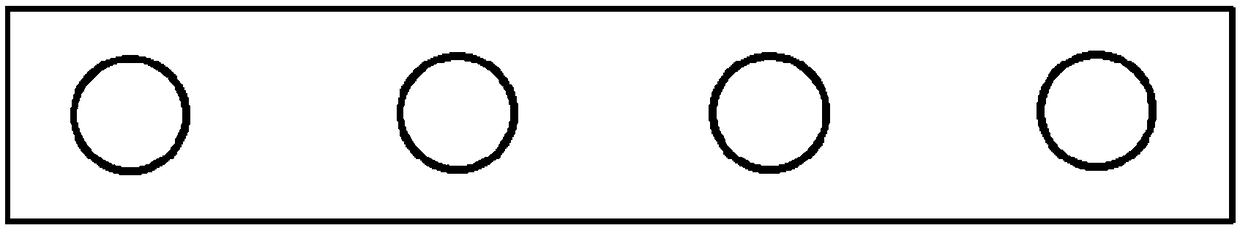

[0032] Four nozzle arrangement. The electrospinning method of free liquid surface four nozzle arrangement, comprises the following steps:

[0033] Step 1: Align the four free surface nozzles according to the following figure 1 , 2 , The three positions shown in 3 are placed under the receiving device, and the free liquid surface at the top of the nozzle is 200mm away from the receiving device. The free surface nozzle adopts an umbrella-shaped nozzle with a diameter of 25mm, the distance between the nozzles is set to 30-70mm, and the running speed of the base cloth of the receiving device is set to 2m / min.

[0034] Step 2: Calculating the critical voltage value (minimum voltage value at which filaments can be produced) of each spray head from the liquid surface through electric field simulation.

[0035] Using the finite element simulation software to simulate the electric field of the arrangement of four free liquid surface nozzles under different nozzle spacing, the critic...

Embodiment 2

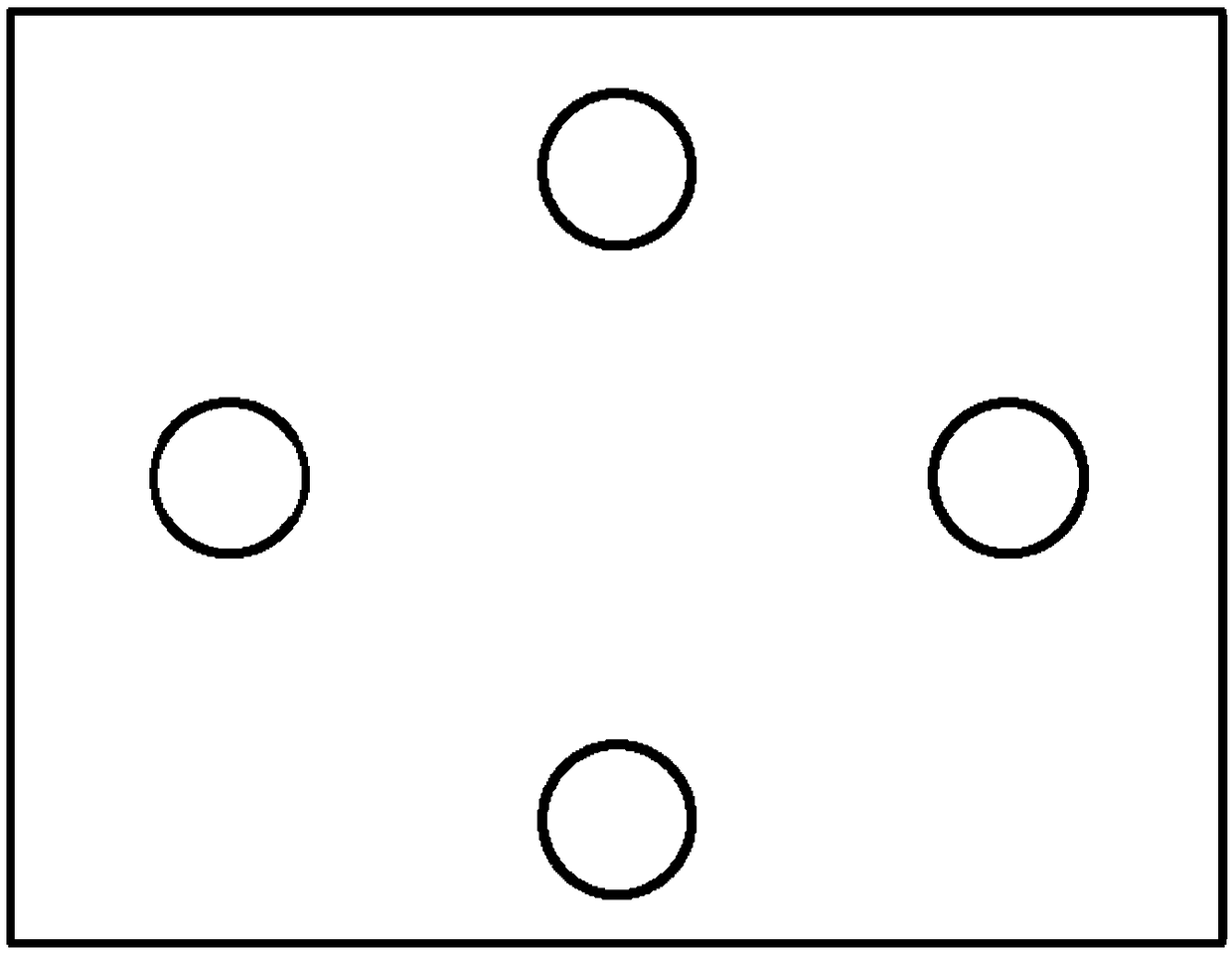

[0039] Arrangement of five nozzles. The electrospinning method of free liquid surface five nozzle arrangement, comprises the following steps:

[0040] Step 1: Align the five free surface nozzles according to Figure 4 , 5 , The three positions shown in 6 are placed under the receiving device, and the free liquid surface at the top of the nozzle is 200mm away from the receiving device. The free surface nozzle adopts an umbrella-shaped nozzle with a diameter of 25mm, the distance between the nozzles is set to 30-70mm, and the running speed of the base cloth of the receiving device is set to 2m / min.

[0041] Step 2: Calculating the critical voltage value (minimum voltage value at which filaments can be produced) of each spray head from the liquid surface through electric field simulation.

[0042] Using the finite element simulation software, the electric field simulation of five free liquid surface nozzle arrangements under different nozzle spacings was carried out to obtain ...

Embodiment 3

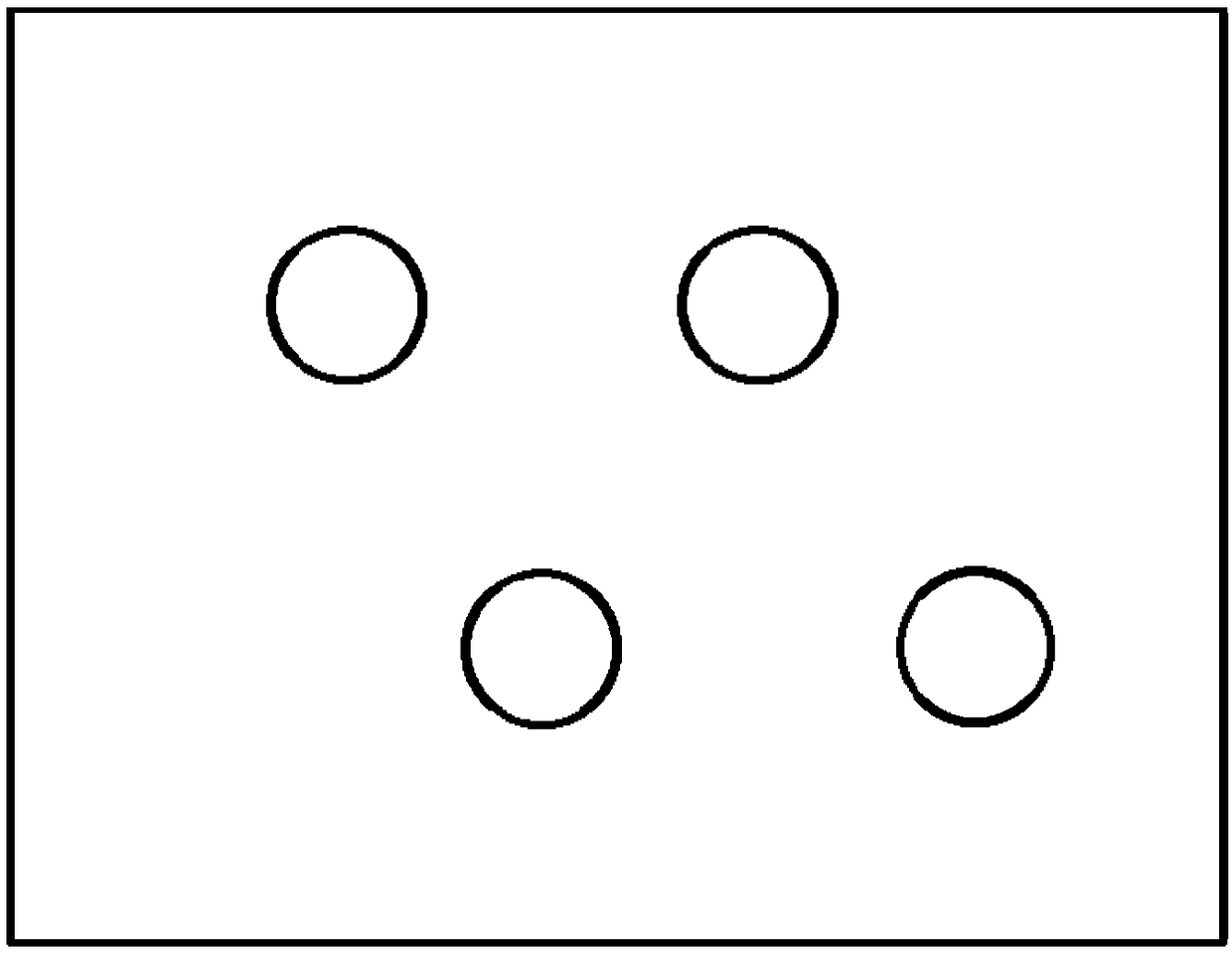

[0046] Nine nozzle arrangement. The electrospinning method of free liquid surface nine nozzle arrangement, comprises the following steps:

[0047] Step 1: Align the nine free surface nozzles according to the following Figure 7 , 8 The two positions shown are placed under the receiving device, and the free liquid surface at the top of the nozzle is 200mm away from the receiving device. The free surface nozzle adopts an umbrella-shaped nozzle with a diameter of 25mm, the distance between the nozzles is set to 30-70mm, and the running speed of the base cloth of the receiving device is set to 2m / min.

[0048] Step 2: Calculating the critical voltage value (minimum voltage value at which filaments can be produced) of each spray head from the liquid surface through electric field simulation.

[0049] Using the finite element simulation software to simulate the electric field of nine free liquid surface nozzle arrangements under different nozzle spacing, the critical voltage valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com