Catalyst and a Method for Cracking Hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

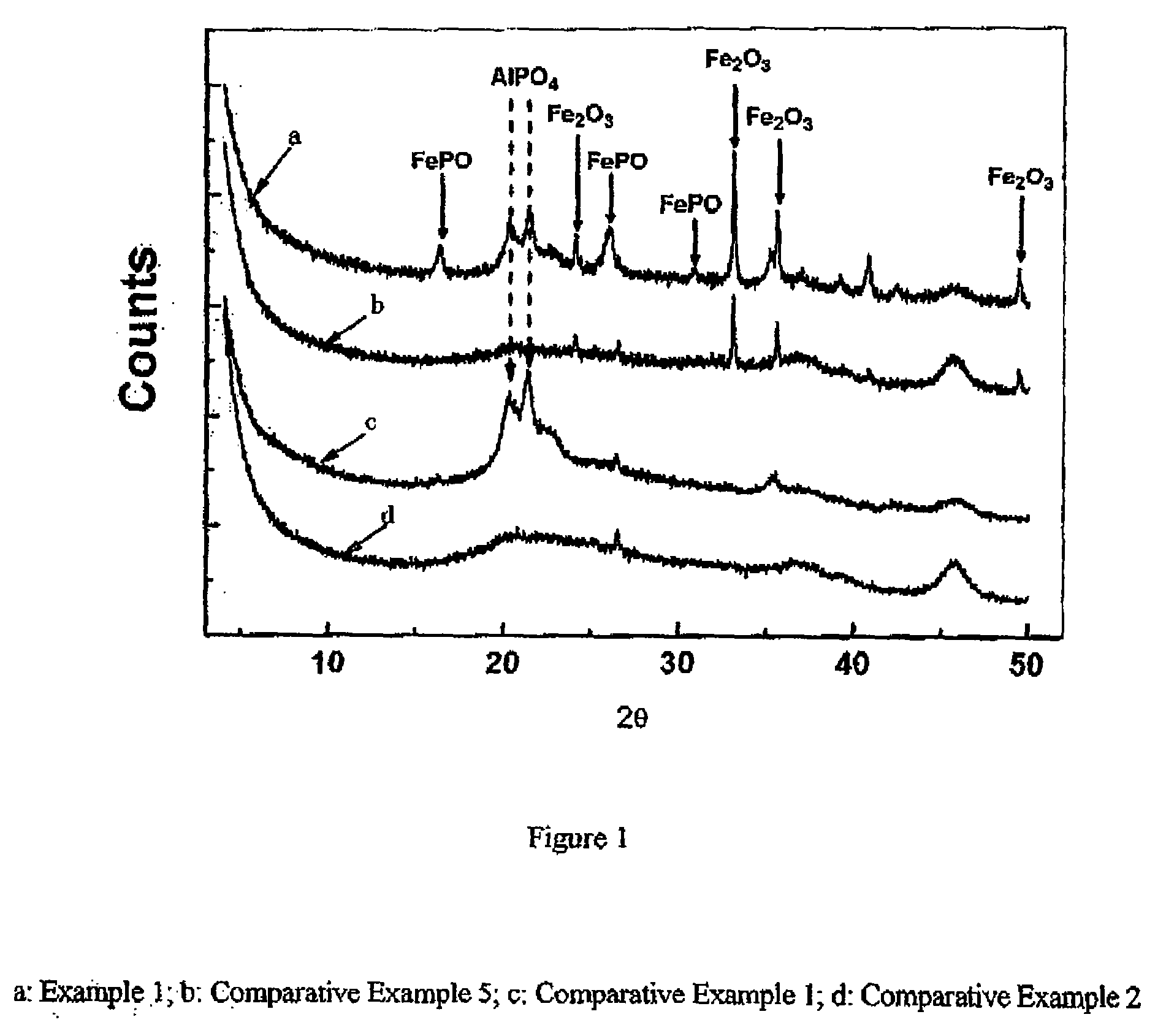

Example 1

[0064]The preparation of phosphorus-alumina sol: 1.05 kg pseudoboehmite (dry basis) and 3.35 kg deionized water was mixed together and stirred for 30 min, then 4.9 kg concentrated H3PO4 (chemical pure, 85 wt % of H3PO4) was added into the slurry under stirring. The obtained slurry was heated to 70° C. and reacted for 45 min at this temperature to form the colorless and transparent phosphorus-alumina sol with a P2O5 content of 30.6 wt % and an Al2O3 content of 10.5 wt % as well as pH=1.7.

[0065]1.75 kg A1 (dry basis), 1.4 kg kaolin (dry basis), 0.65 kg pseudoboehmite (dry basis), 6.2 kg deionized water and 2.79 kg alumina sol were mixed together and stirred for 120 min, then 1 L aqueous FeCl3.6H2O solution (having 100 g Fe2O3) was added into the slurry under stirring. The pH value of the slurry is 3.0. After stirring for another 45 min, 1.22 kg phosphorus-alumina sol was added into the slurry and stirred evenly. Microspheres with average particle size of 65 μm were obtained b...

Example

Example 2

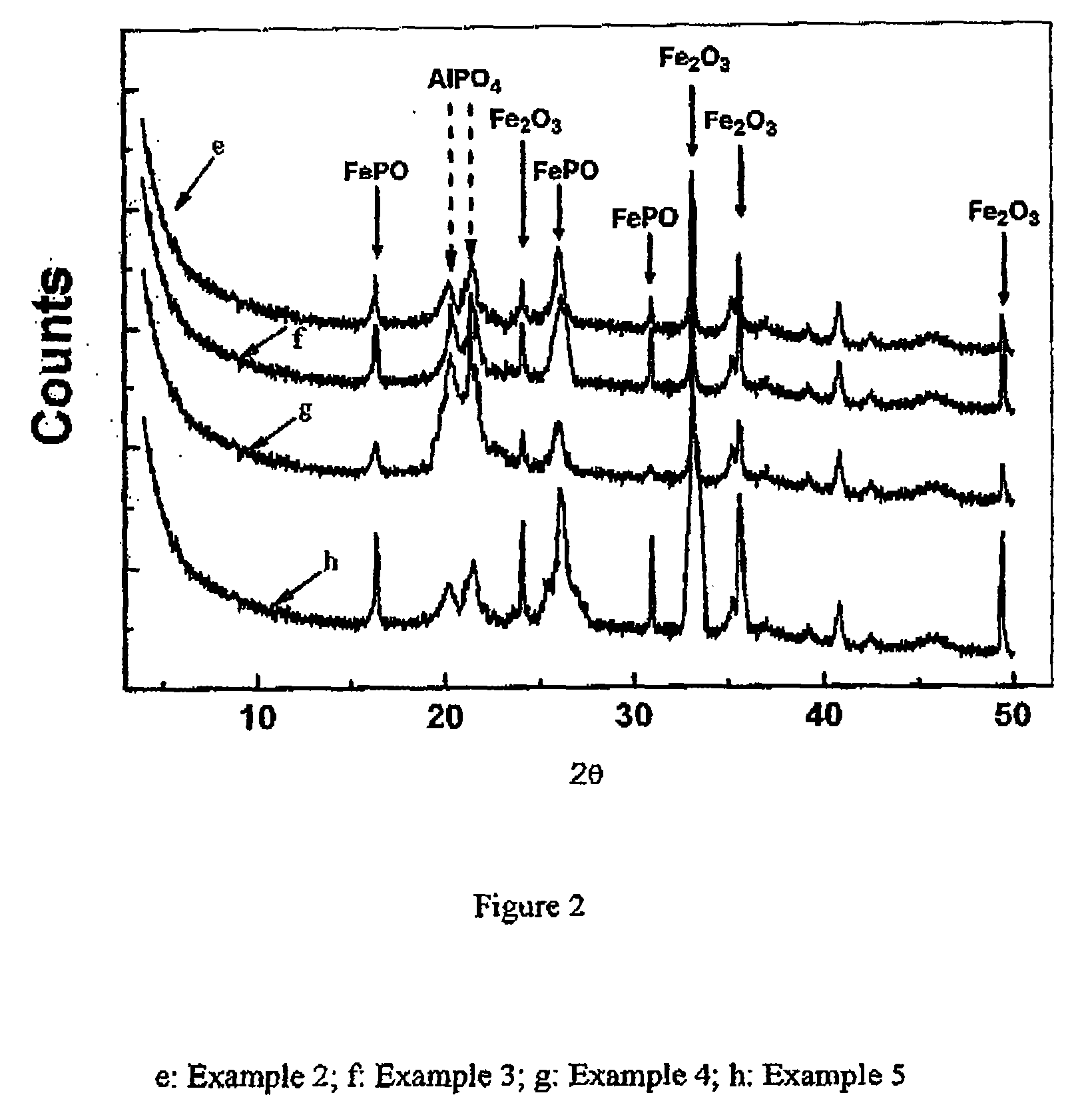

[0067]1.84 kg A1 (dry basis), 1.33 kg kaolin (dry basis), 0.98 kg pseudoboehmite (dry basis), 7.2 kg deionized water and 2.79 kg alumina sol were mixed together and stirred for 120 min, then 1 L aqueous FeCl3.6H2O solution (having 250 g Fe2O3) was added into the slurry under stirring. The pH value of the slurry is 3.0. The slurry was stirred for another 45 min. Then microspheres with average particle size of 65 μm were obtained by the spray-drying of the slurry at input temperature of 500V and exhaust (output) temperature of 180° C. The microspheres with 36.8 wt % A1, 26.6 wt % kaolin, 31.6 wt % Al2O3 and 5.0 wt % Fe additive (calculated by Fe2O3) were obtained after calcination at 500° C. for 1 h.

[0068]1 kg microspheres obtained above (dry basis), 10 L deionized water and 100 g (NH4)2HPO4 were mixed together. The obtained slurry was heated to 60° C. under stirring and reacted for 20 min at this temperature. The slurry was vacuum-filtrated and dried. The catalyst ZJ2 with 3...

Example

Example 3

[0070]1.94 kg A1 (dry basis), 1.91 kg pseudoboehmite (dry basis), 7.2 kg deionized water and 2.79 kg alumina sol were mixed together and stirred for 120 min, then 1 L aqueous FeCl3.6H2O solution (having 550 g Fe2O3) was added into the slurry under stirring. The pH value of the slurry is 3.0. The slurry was stirred for another 45 min. Then microspheres with average particle size of 65 μm were obtained by the spray-drying. Of the slurry at input temperature of 500V and exhaust temperature of 180° C. The microspheres with 38.8 wt % A1, 50.2 wt % Al2O3 and 11 wt % Fe additive (calculated by Fe2O3) were obtained after calcination at 500° C. for 1 h.

[0071]1 kg microspheres obtained above (dry basis), 10 L deionized water and 210 g (NH4)2HPO4 were mixed together. The obtained slurry was heated to 60° C. under stirring and reacted for 20 min. The slurry was vacuum-filtrated and dried. The catalyst ZJ3 with 35 wt % A1, 45.1 wt % Al2O3, 9.9 wt % Fe additive (calculated by Fe2O3) and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com