METHOD OF PRODUCING MENINGOCOCCAL MENINGITIS VACCINE FOR NEISSERIA MENINGITIDIS SEROTYPES A, C, Y, and W-135

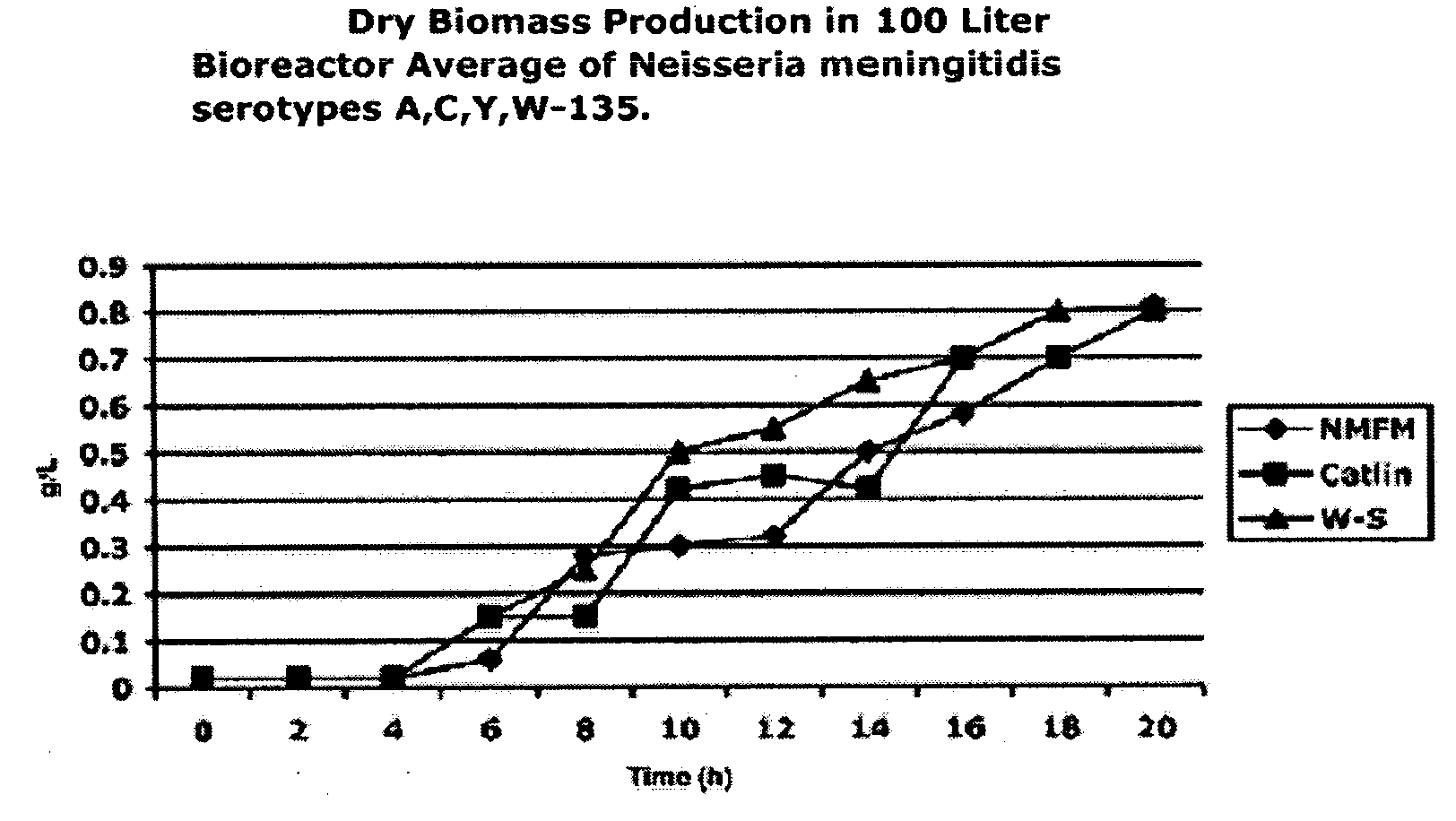

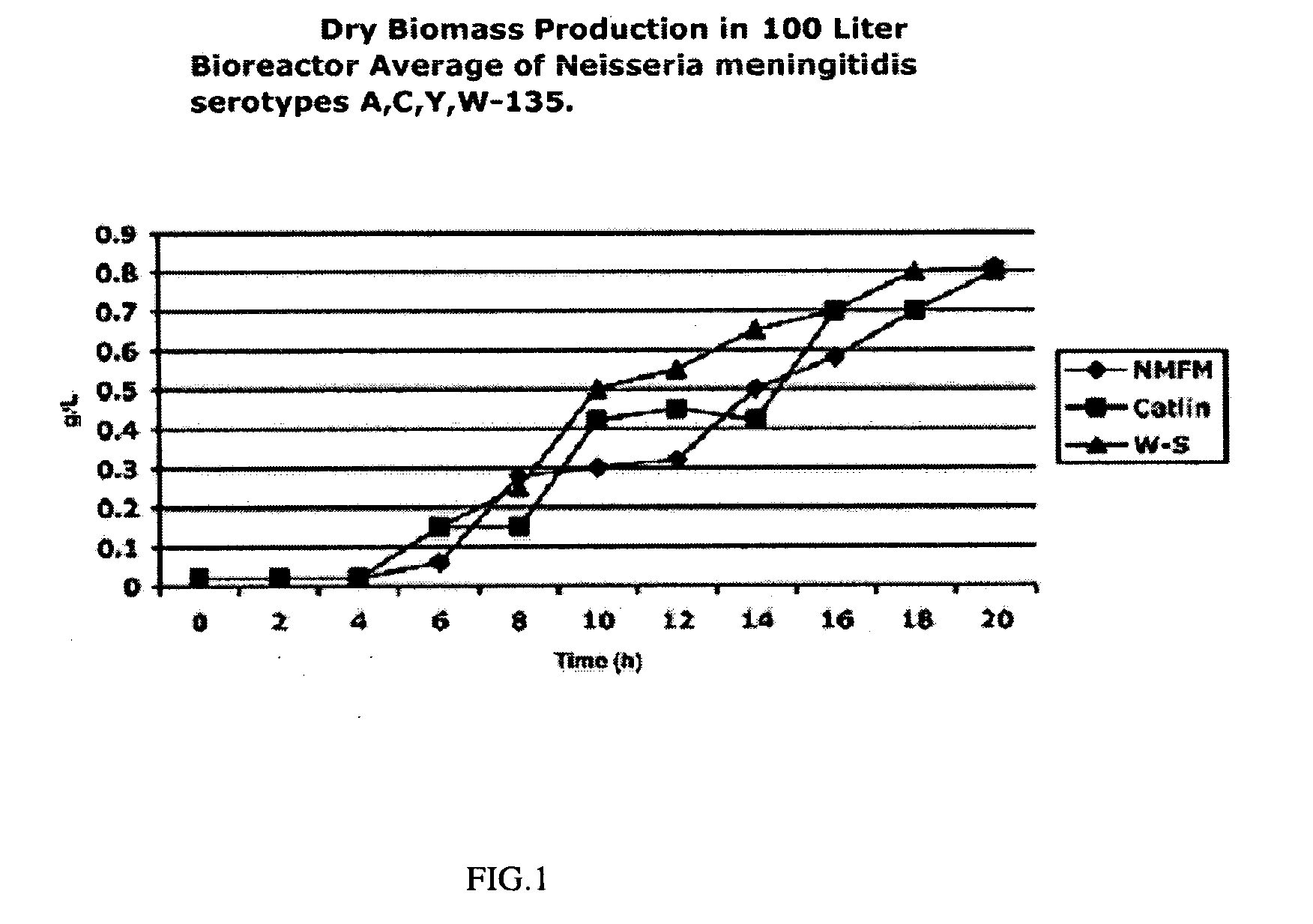

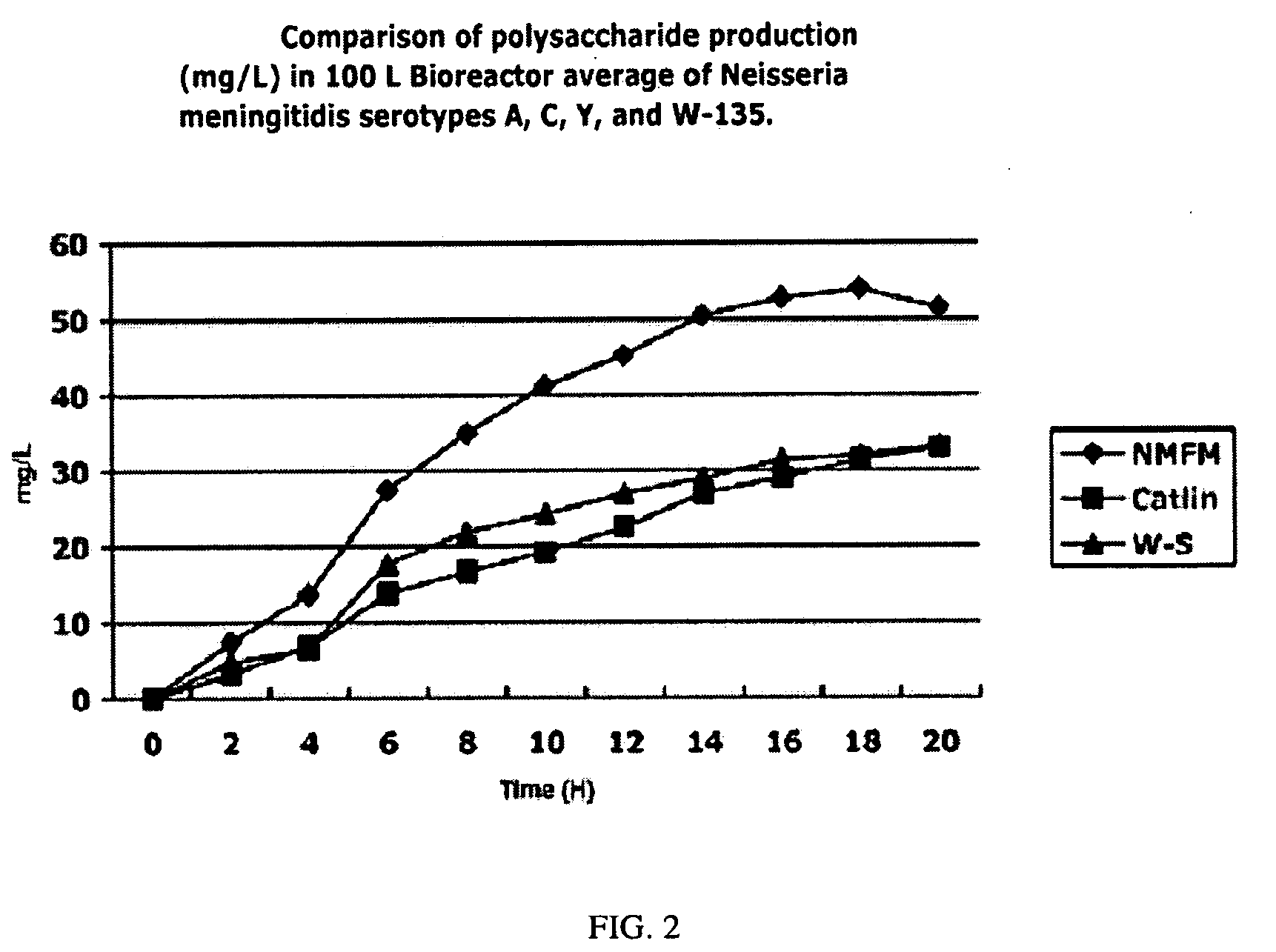

a technology of meningitis and vaccine, applied in the field of vaccines, can solve the problems of reduced local immunity, increased risk of meningitis, brain damage, hearing loss or learning disability, etc., to maximize the yield of capsular polysaccharides, minimize the yield of cellular biomass and endotoxins, and maximize the yield of precipitated polysaccharides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Fermentation Procedure

[0084]The working Seed Bank stocks of Neisseria meningitidis A, C, Y, W-135 were kept frozen in glycerol solution at −80° c. The stock tubes were thawed in running cold water and the outer surface of the tube is disinfected with ethanol, and butterfly streaked with a loop-full of culture of Neisseria meningitidis onto two Columbia agar plates. The plates were incubated overnight (18 hours) at 37° c. in an incubator with 6% CO2 atmosphere. The cultures were re-streaked on fresh plates to isolate pure cultures of Neisseria meningitidis and incubated at 37° c. in 6% CO2 atmosphere overnight for 12 hours. Bacterial colonies from two plates were collected with a sterile cotton swab and suspended in two 10 ml aliquots of Shedulars Broth® (Remel, Inc®) in separate 15 ml centrifuge tubes and re-suspended into 50 ml media contained in a 200 ml flask. The bacteria were allowed to grow at 35° C. under normal atmospheric pressure shaking the flask at 125 rpm for about 3 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com