Pile driver

a technology of driver and ram, which is applied in the field of ram drivers, can solve the problems of reducing the possibility of operator error, reducing the possibility of ram striking the frame, and reducing the overhead spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

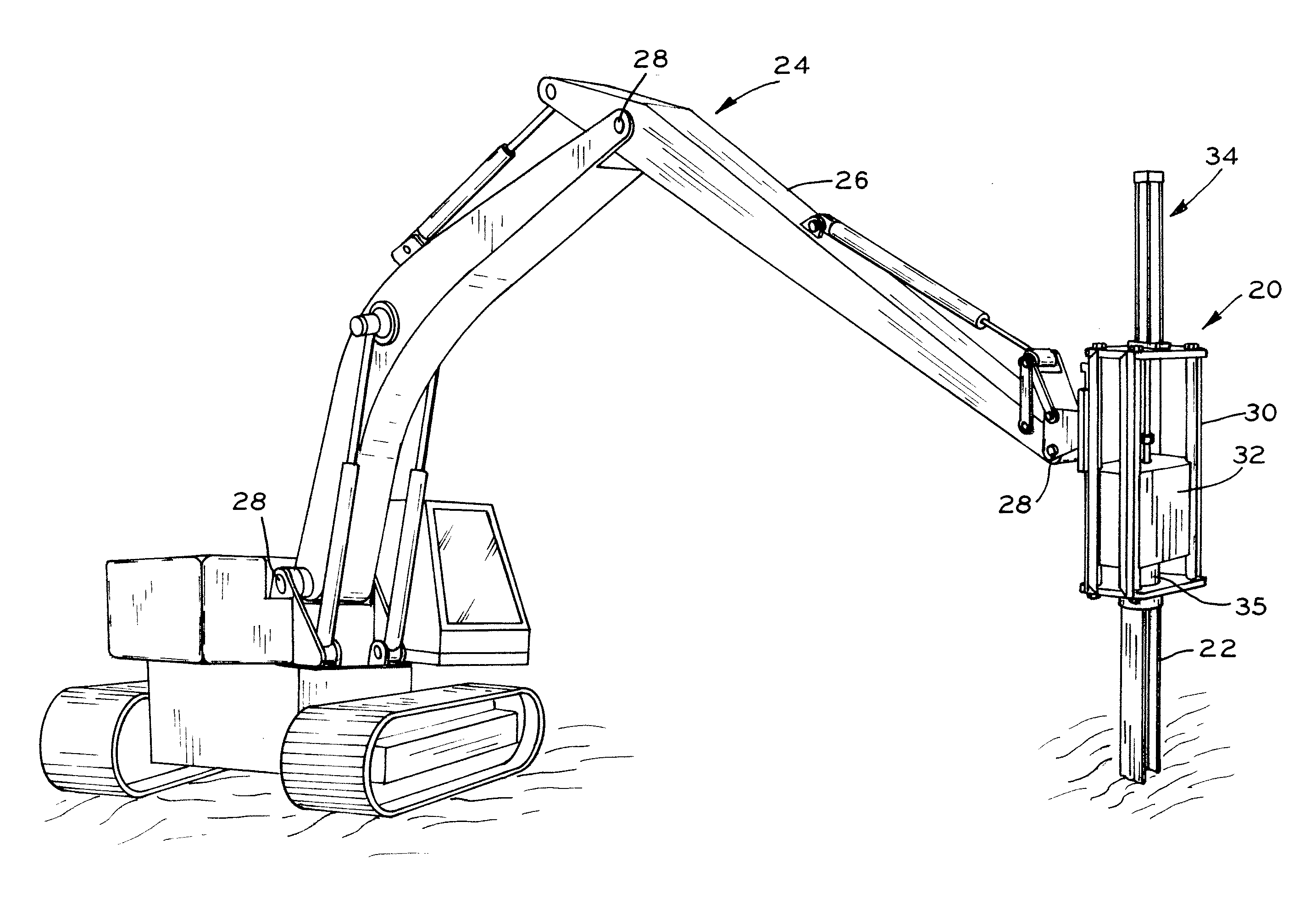

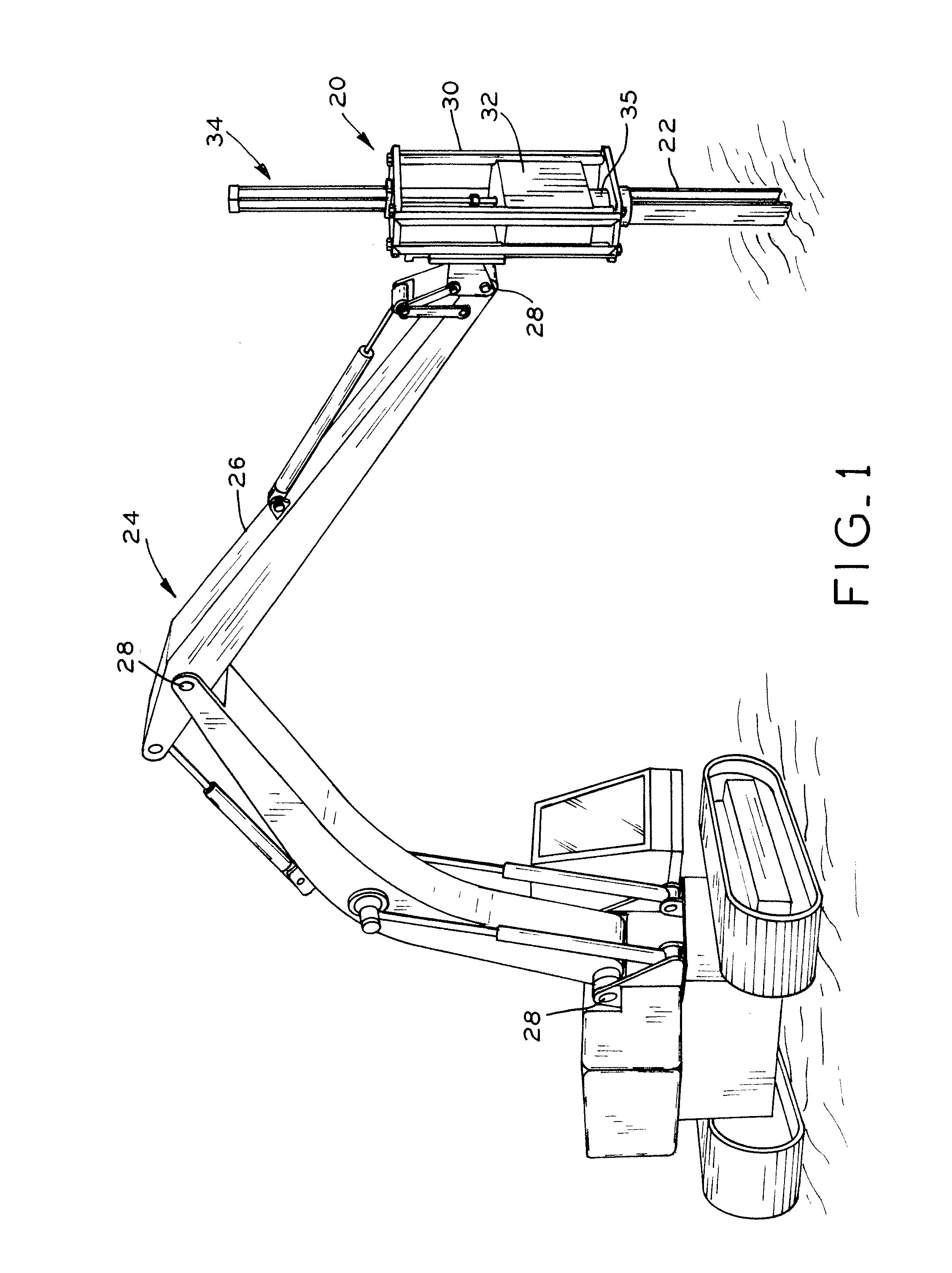

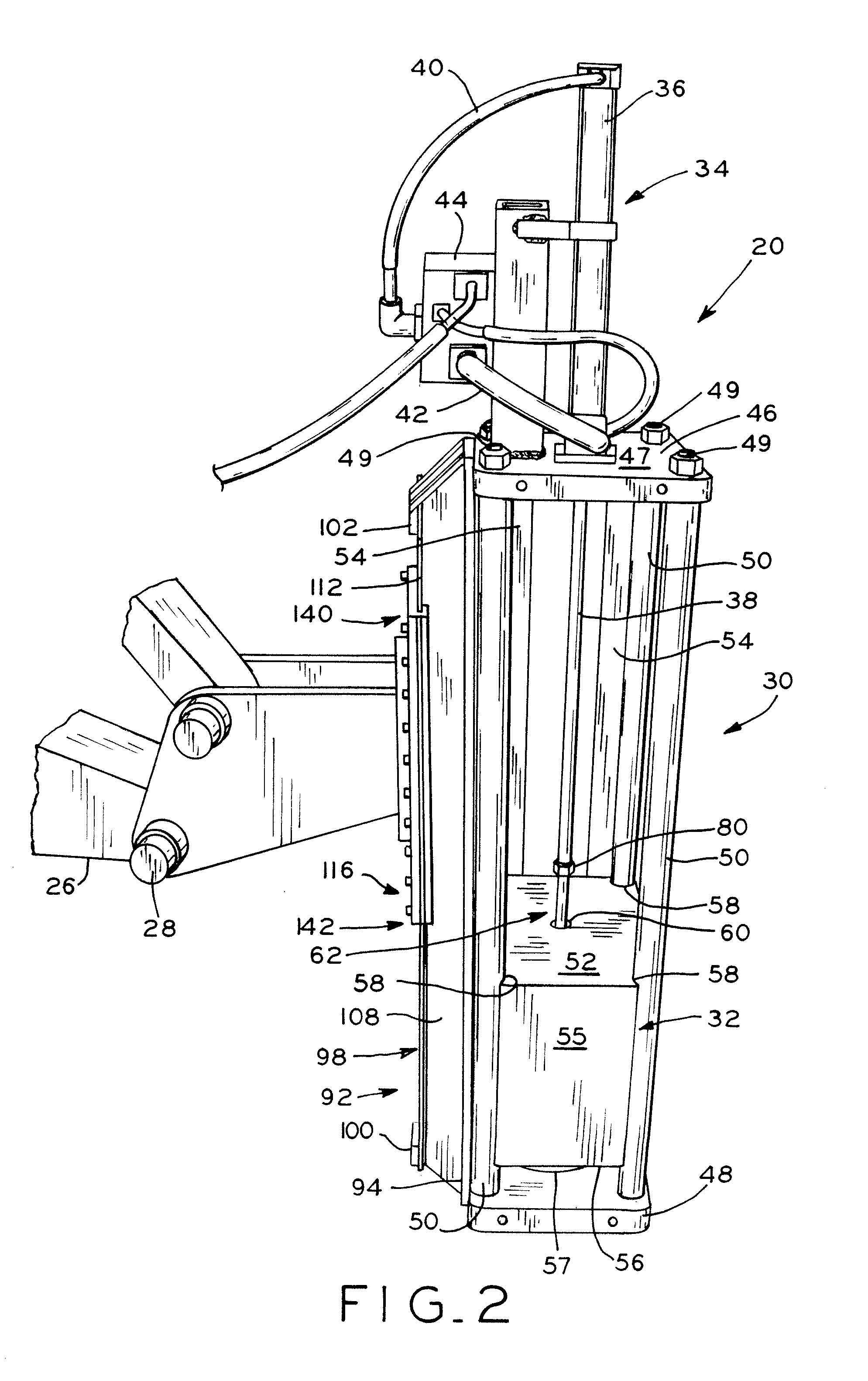

[0029]As illustrated in FIG. 1, hammer 20, in operation, is placed on top of pile 22 by excavator 24. Excavator 24 includes boom 26 that articulates at several joints 28, as is well known in the art, to position hammer 20. In the present embodiment, hammer 20 includes frame 30, ram 32 positioned within frame 30, and a ram lifting mechanism in the form of cylinder assembly 34 mounted to the top of frame 30. In operation, ram 32 is raised by hydraulic or pneumatic cylinder assembly 34 and then dropped onto pile 22. Commonly, a drive cap (not illustrated) is placed over the end of the pile to reduce deformation, or mushrooming, of the top of the pile. The drive cap includes a substantially flat upper surface and a recess in a bottom surface that mates with the top of the pile. When a drive cap is used, hammer frame 30 rests on top of the upper surface of the drive cap. Piles typically include a consistent H-shaped or I-shaped cross-section, e.g., that extend along the length of the pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com