Suction port assembly of vacuum cleaner

a vacuum cleaner and suction port technology, applied in the field of vacuum cleaners, can solve the problems of user inconvenience, increased complexity of the structure, and drawbacks of the convertible vacuum cleaner, and achieve the effects of reducing the overall height, simple and fast conversion between upright and canister modes, and simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The matters defined in the description such as a detailed construction and elements are provided to assist in a comprehensive understanding of exemplary embodiments of the disclosure. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the disclosure. Also, descriptions of well-known functions and constructions are omitted for clarity and conciseness.

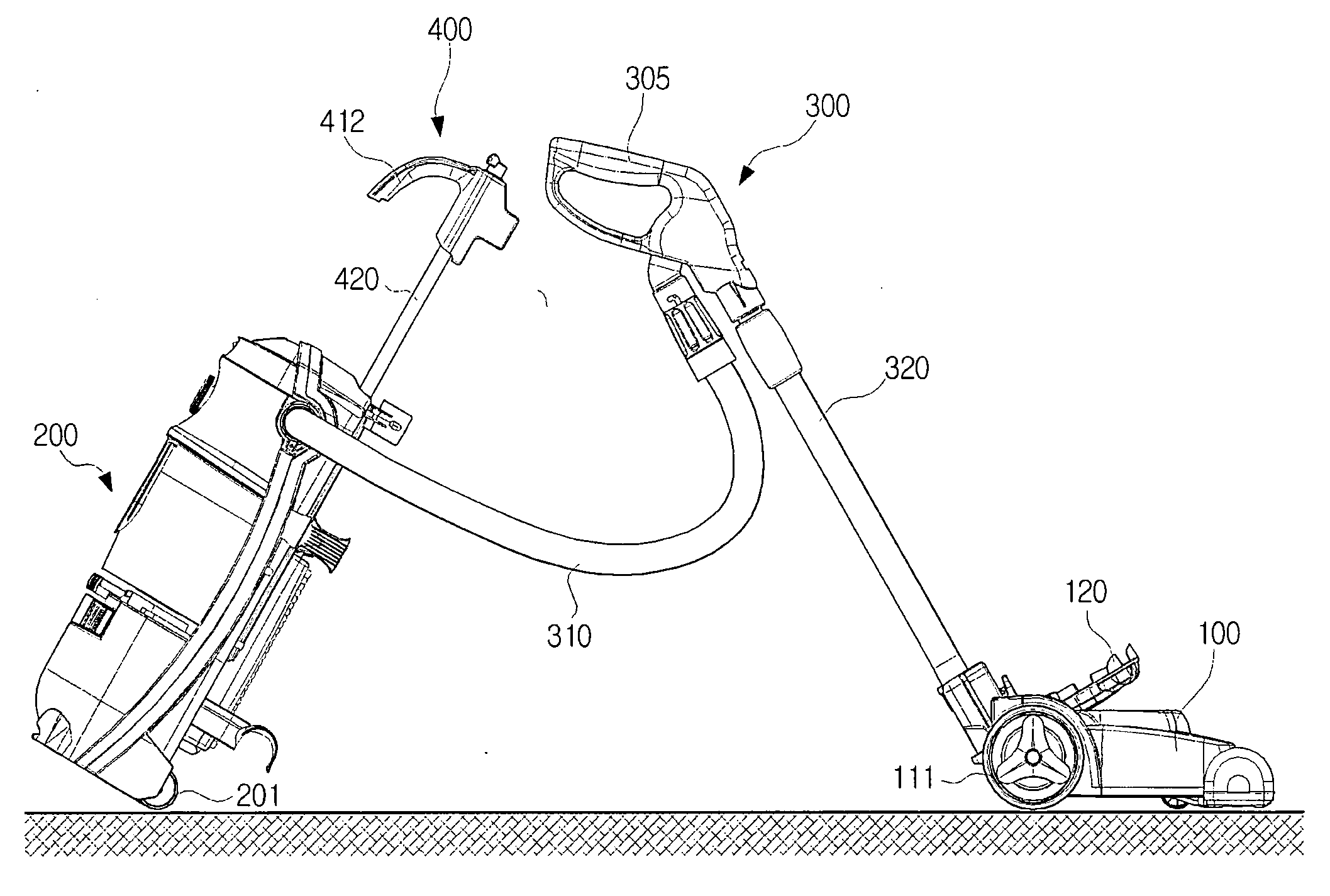

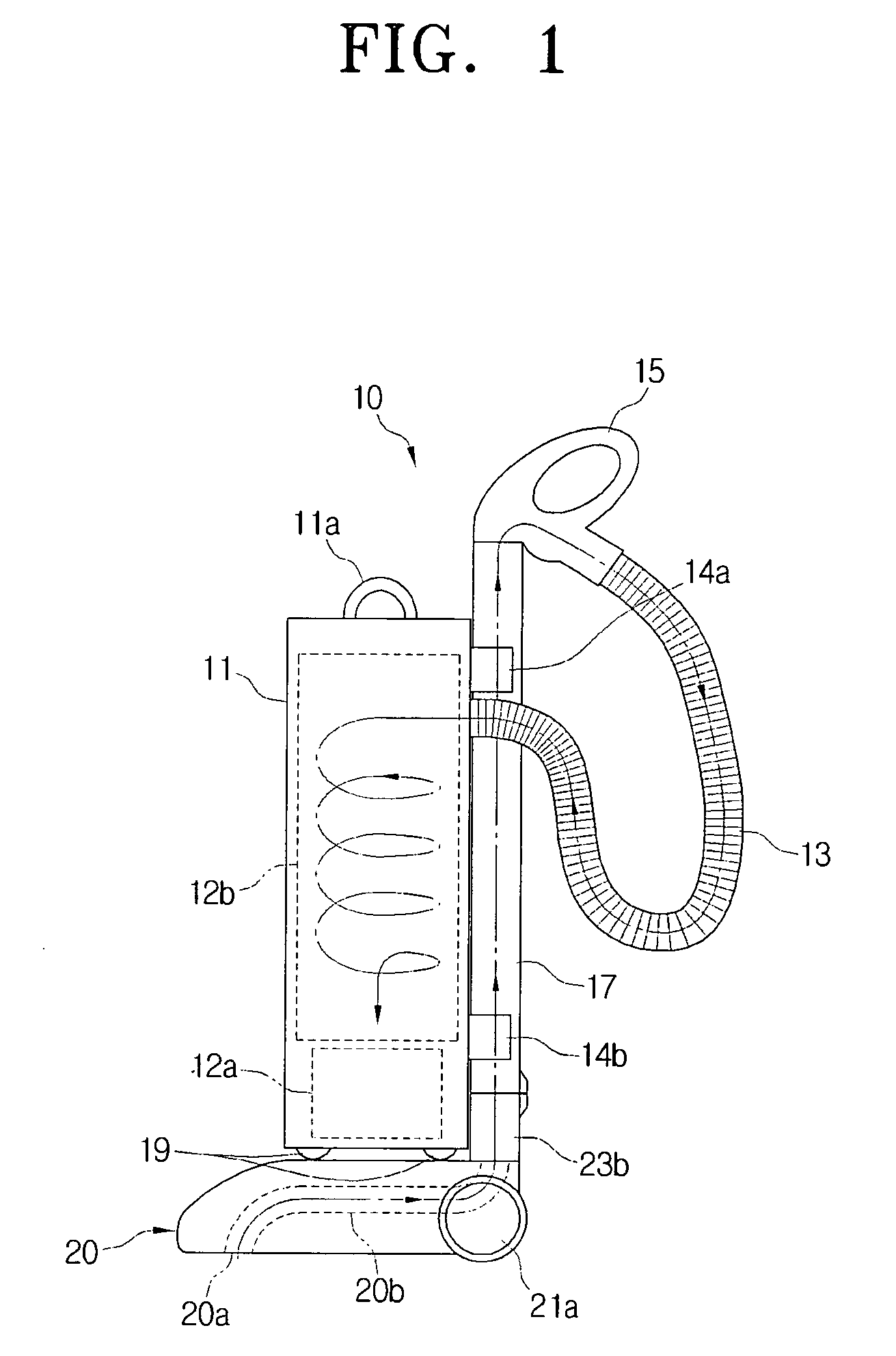

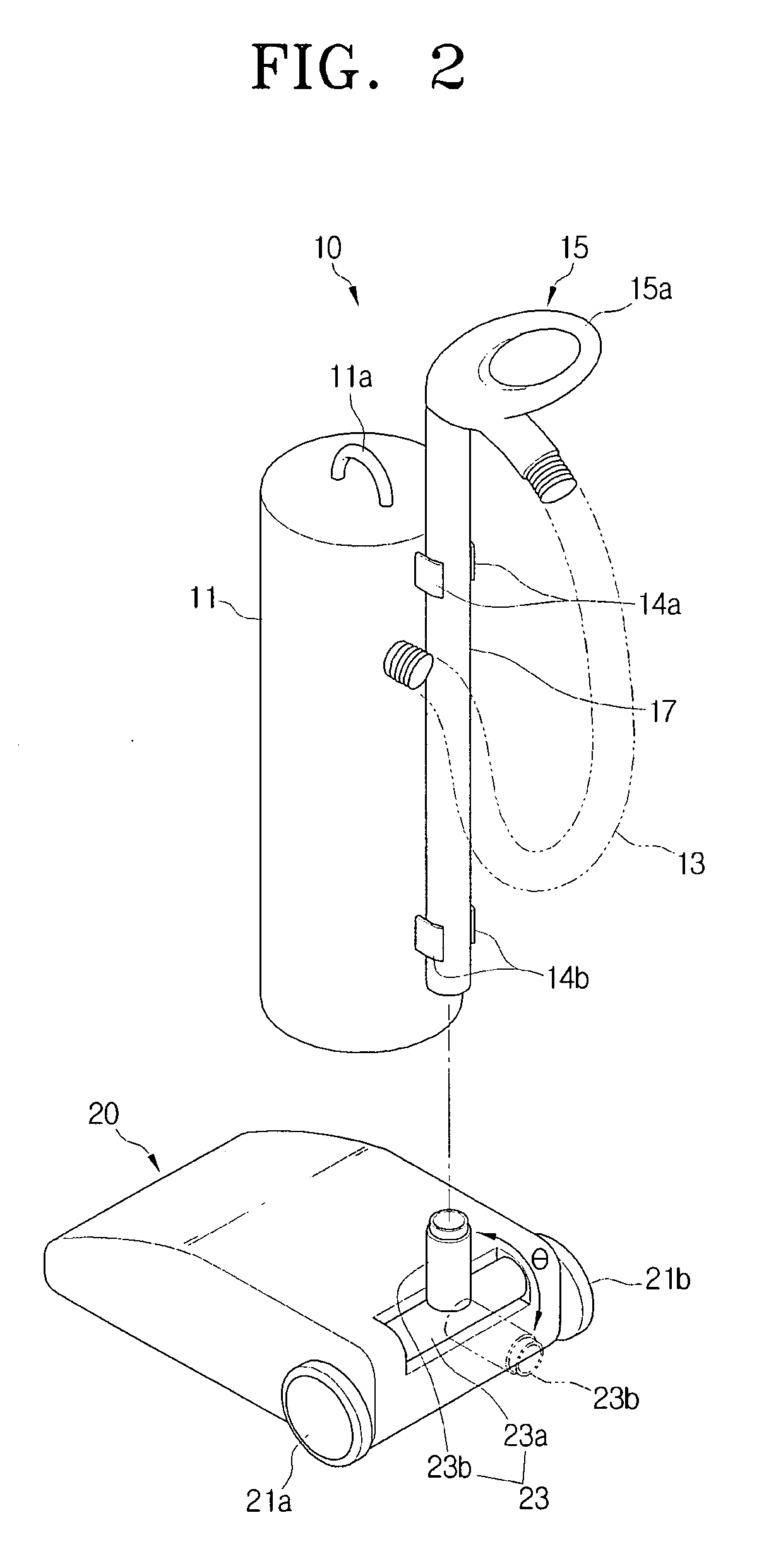

[0038]Referring to FIGS. 1 and 2, a vacuum cleaner according to a first exemplary embodiment of the present disclosure includes a cleaning unit 10 and a suction port assembly 20. The cleaning unit 10 may be separated from the suction port assembly 20 and used separately.

[0039]The cleaning unit 10 may include a cleaner body 11, a hose 13, an operating handle assembly 15, and an extension pipe 17.

[0040]The cleaner body 11 may include a suction motor 12a to generate a suction force inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com