Cooling facility for an electronic component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

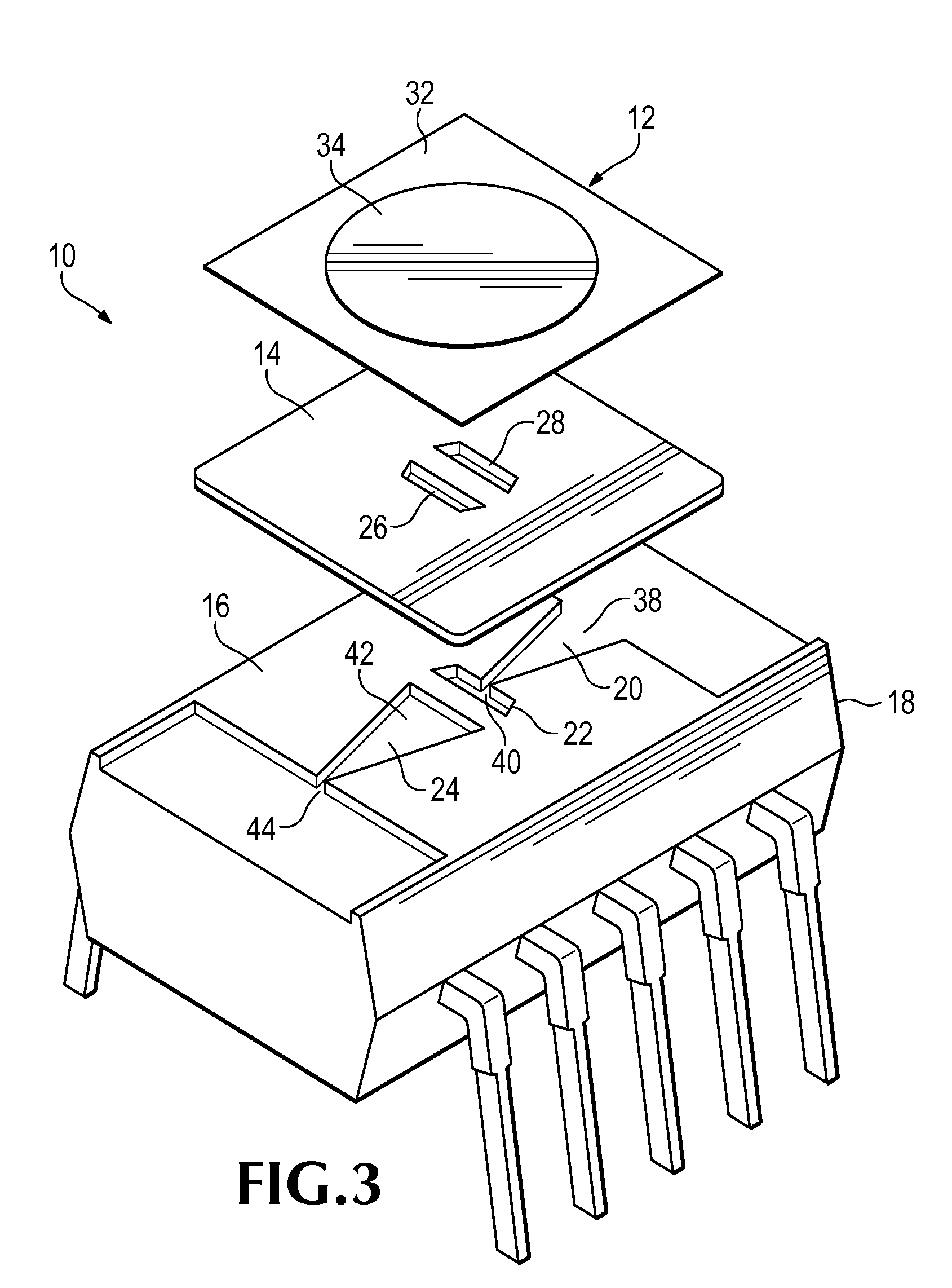

[0018]A preferred embodiment of the cooling facility for an electronic component of the present invention is shown and generally designated by the reference numeral 10.

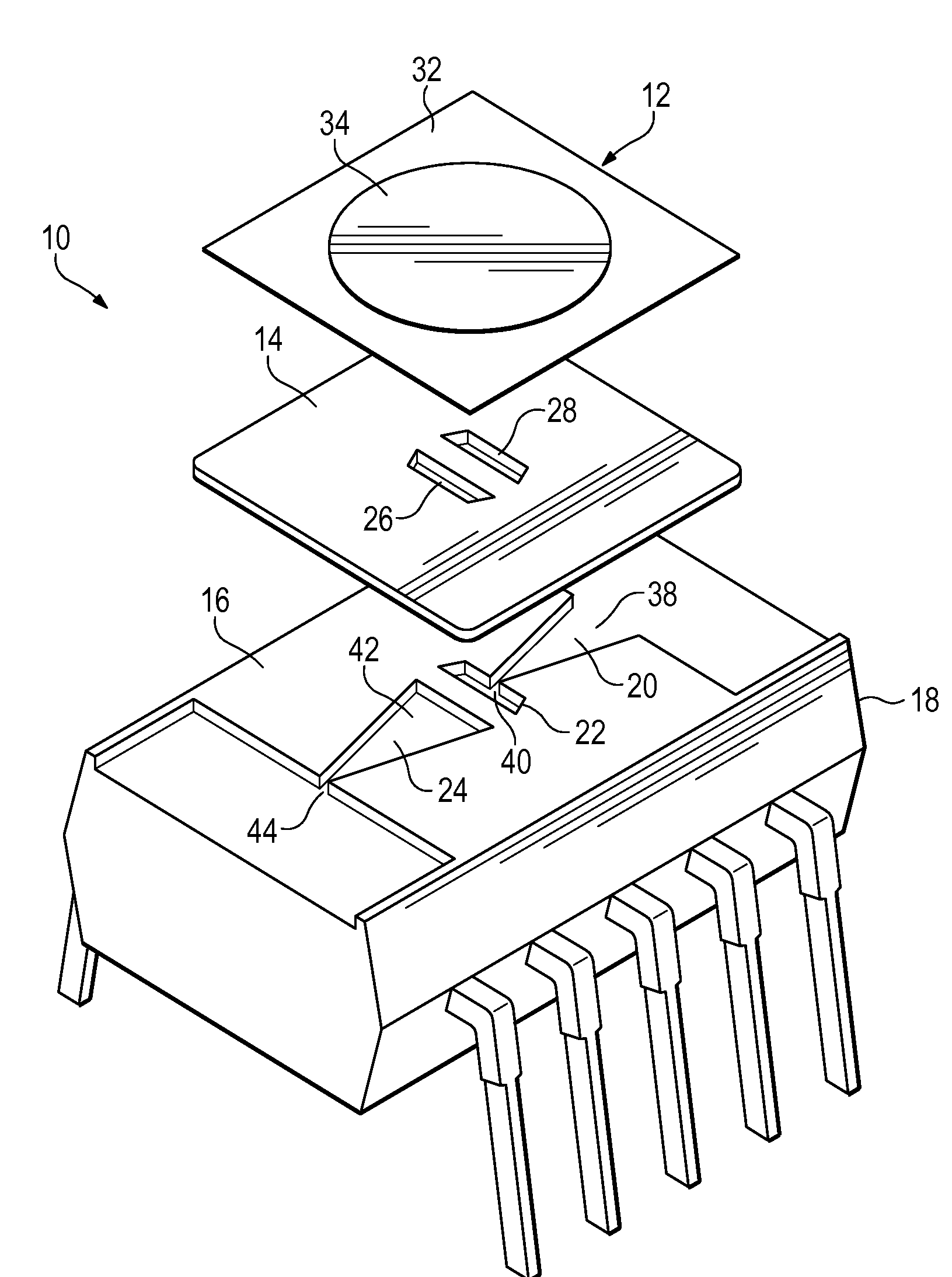

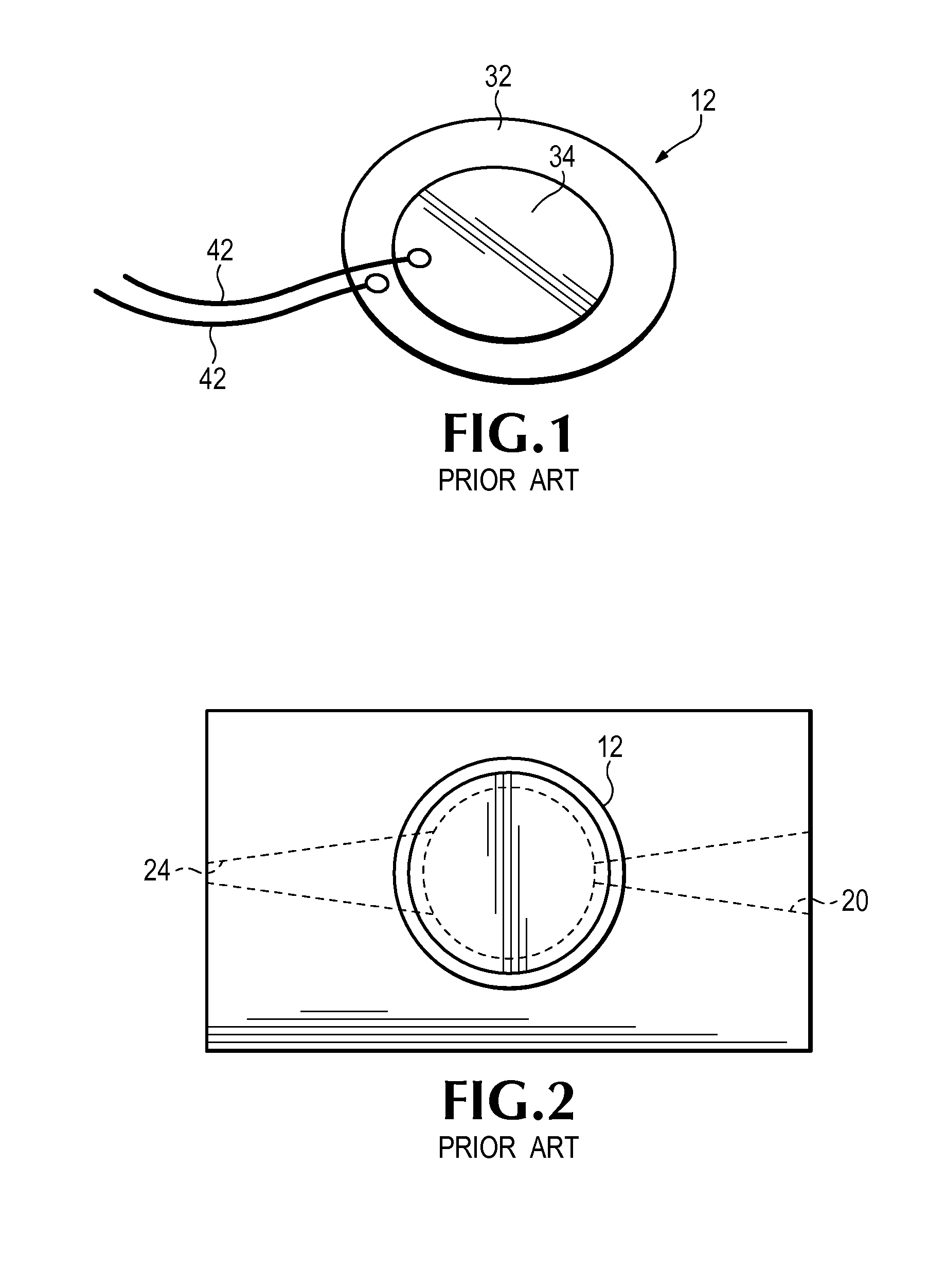

[0019]FIG. 1 illustrates a piezoelectric bending element 12 suitable for use with the current invention known as the CEB-44D06 Piezoelectric Buzzer element manufactured by CUI Inc. of Tualatin, Oreg. More particularly, piezoelectric bending element 12 has a nickel alloy piezoelectric disc backing plate 32 with a circular patch of Lead Zirconate Titanate (PZT) crystal 34 affixed to its center. An electrical potential is created between the piezoelectric disc backing plate 32 and the PZT crystal 34 using wires 42. If the electrical potential is switched at the appropriate rate, the piezoelectric bending element 12 will vibrate, acting as a diaphragm. Piezoelectric disc backing plates 32 are often used to modify the resonant frequency of the PZT crystal 34 as well as to stabilize the brittle PZT crystal 34 and provide a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com