Modular staircase system and kit for erecting a staircase

a modular and staircase technology, applied in the field of stairs, can solve the problems of retaining much of the complexity of each staircase, further difficulties in constructing a staircase, and extremely difficult to determine actual measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

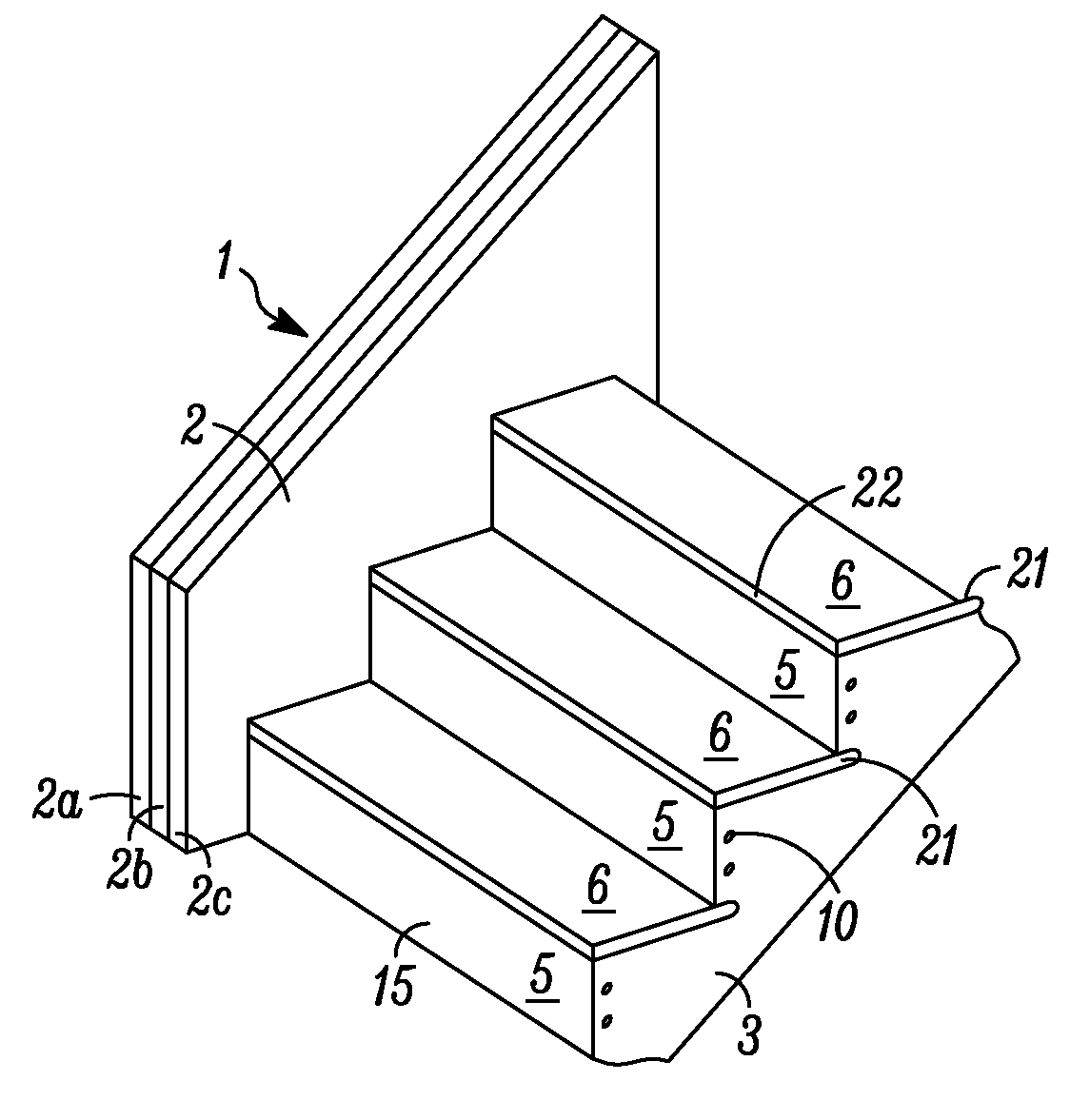

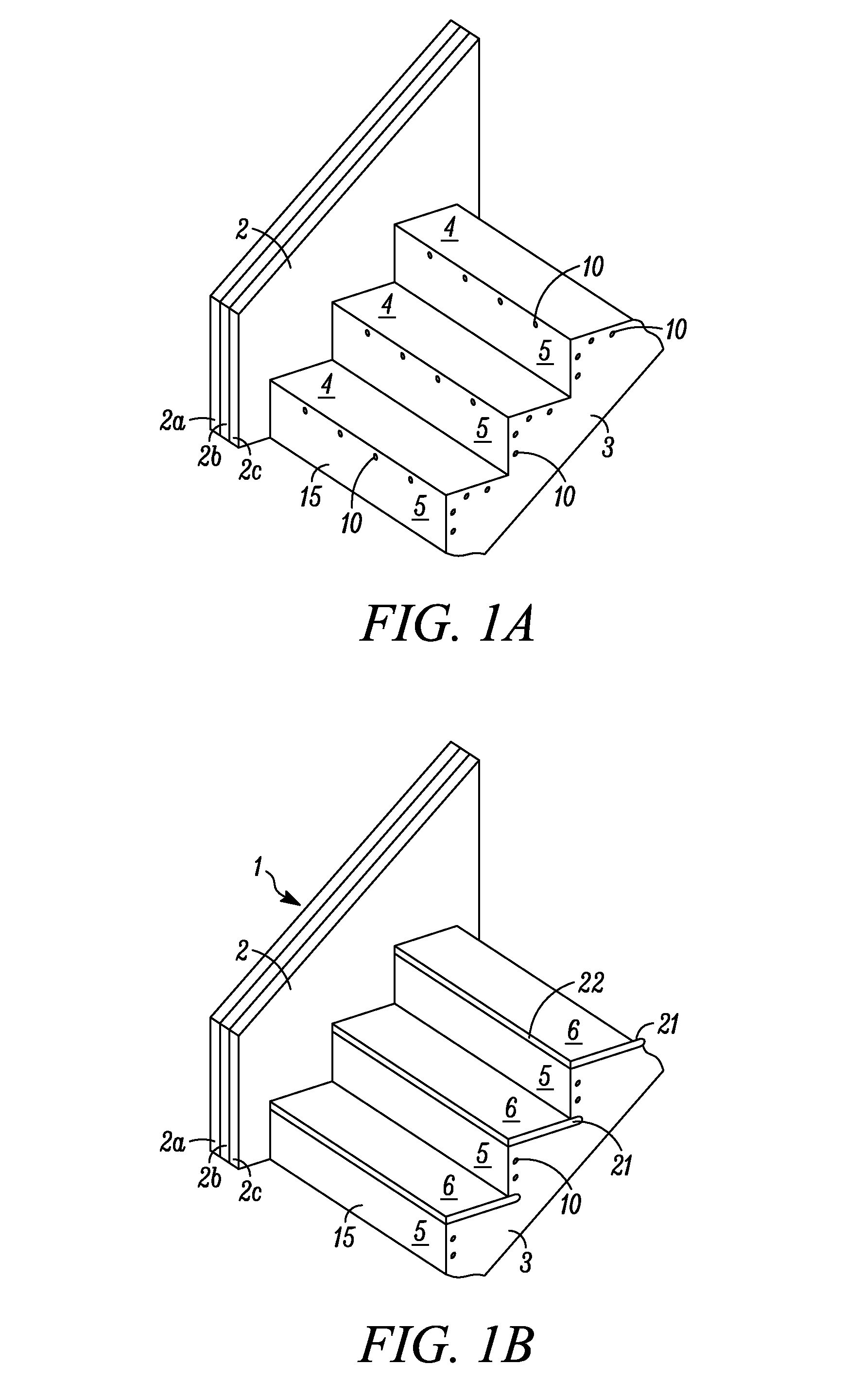

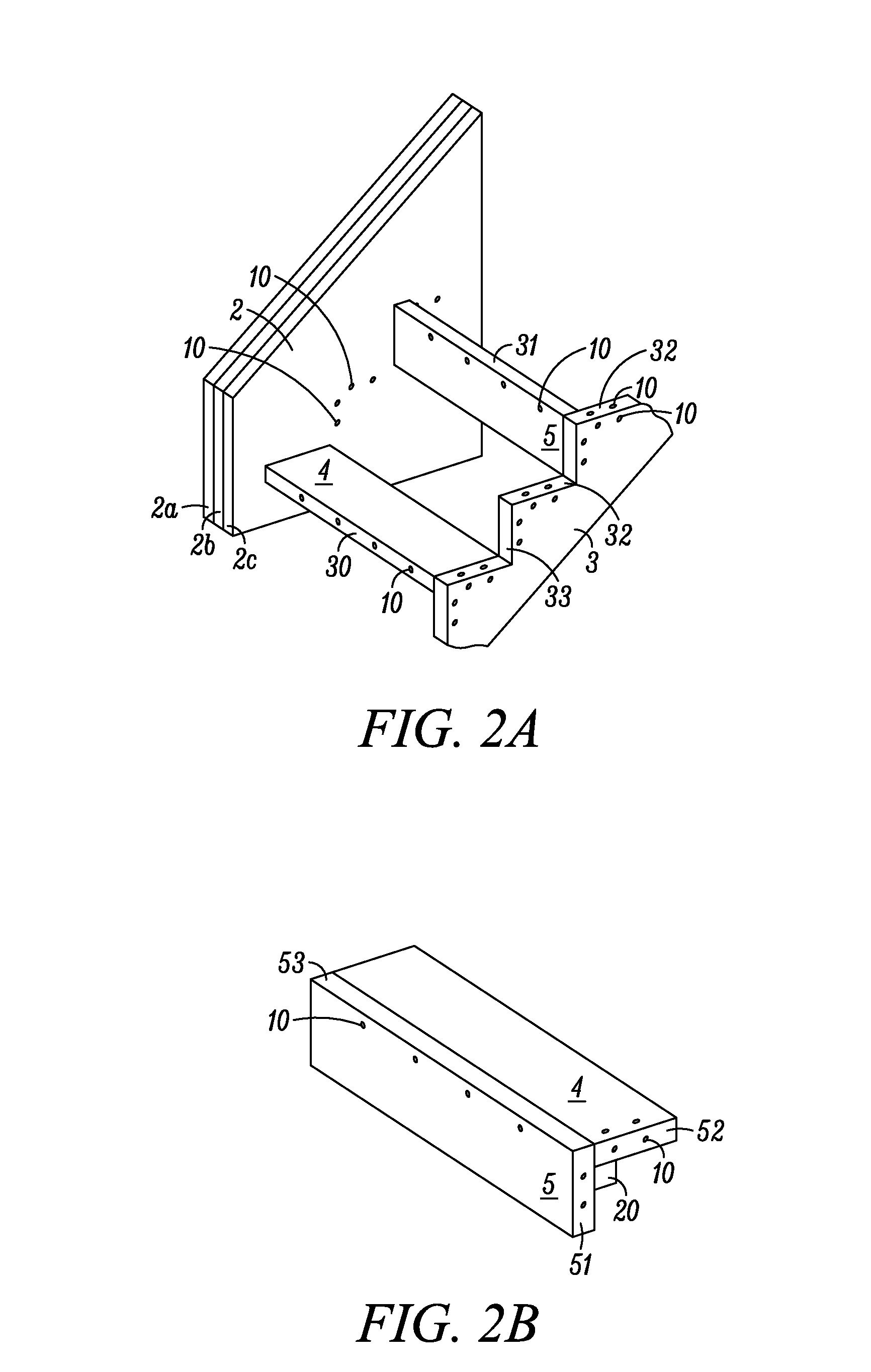

[0034]The general description of the invention and how to manufacture and assemble the kit of parts of the present invention is stated in the Brief Summary above. This detailed description defines the meaning of the terms used herein and specifically describes embodiments in order for those skilled in the art to practice the invention. The above interests in successfully providing an easy to assemble kit of parts for a staircase can readily be seen from the disclosure which follows and are met by the present invention. This detailed description defines the meaning of the terms used herein and specifically describes embodiments in order for those skilled in the art to practice the invention.

[0035]As used herein the term “premeasured” or “measuring” refers to taking measurements on site where the staircase is to be assembled. The measurements include the X, Y and Z (i.e. the rise, run, width and rake) measurements sufficient to construct a staircase. Other measurements including heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com