Transversal generator set and modular design for refurbishment of locomotives

a generator set and modular design technology, applied in the direction of locomotives, transportation and packaging, window arrangements, etc., can solve the problems of lack of standardization, complicated refurbishment of gensets on locomotives of different lengths, lack of standardization in common interface assemblies, etc., to achieve better hp/linear feet ratio and simplify hood designs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

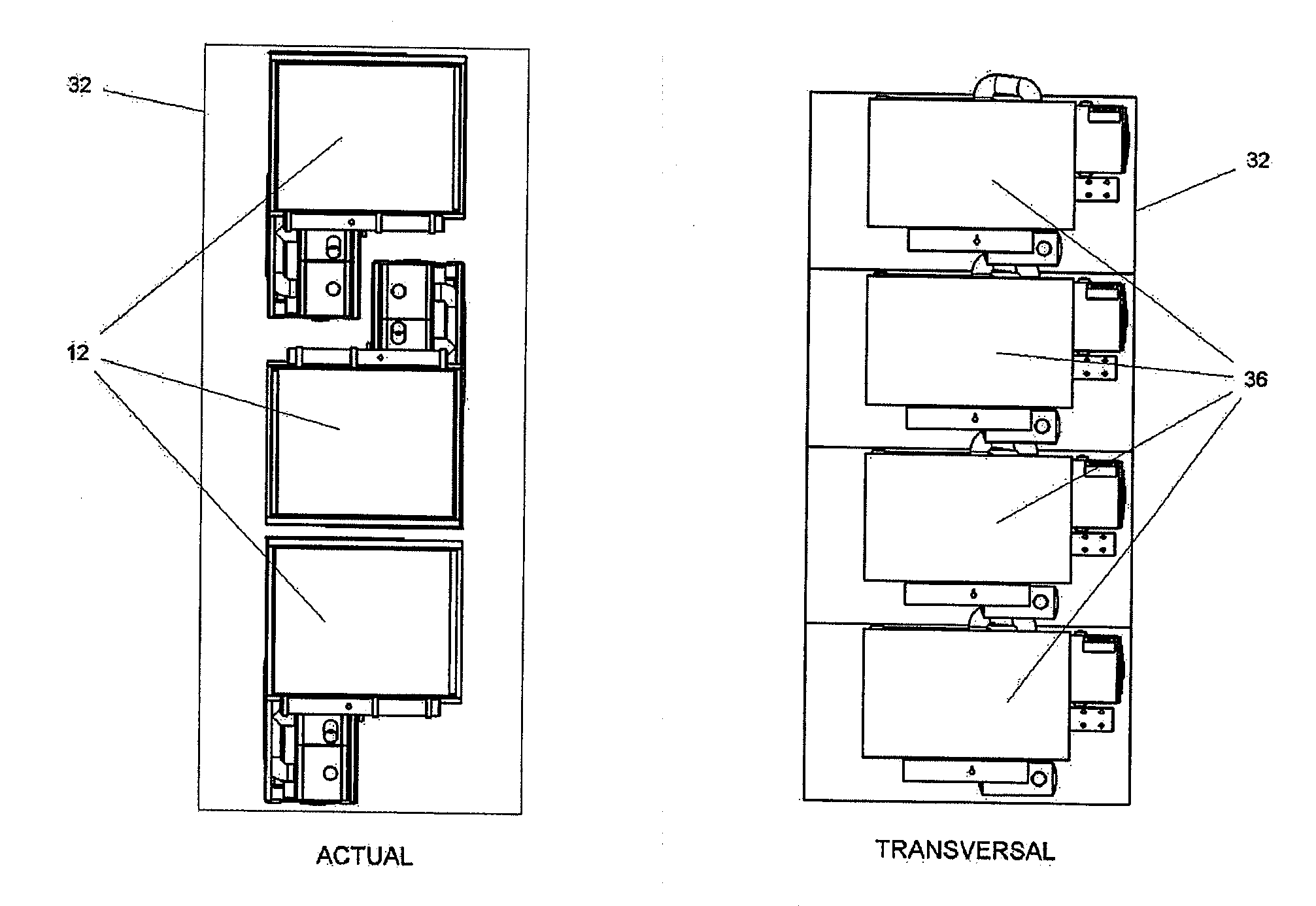

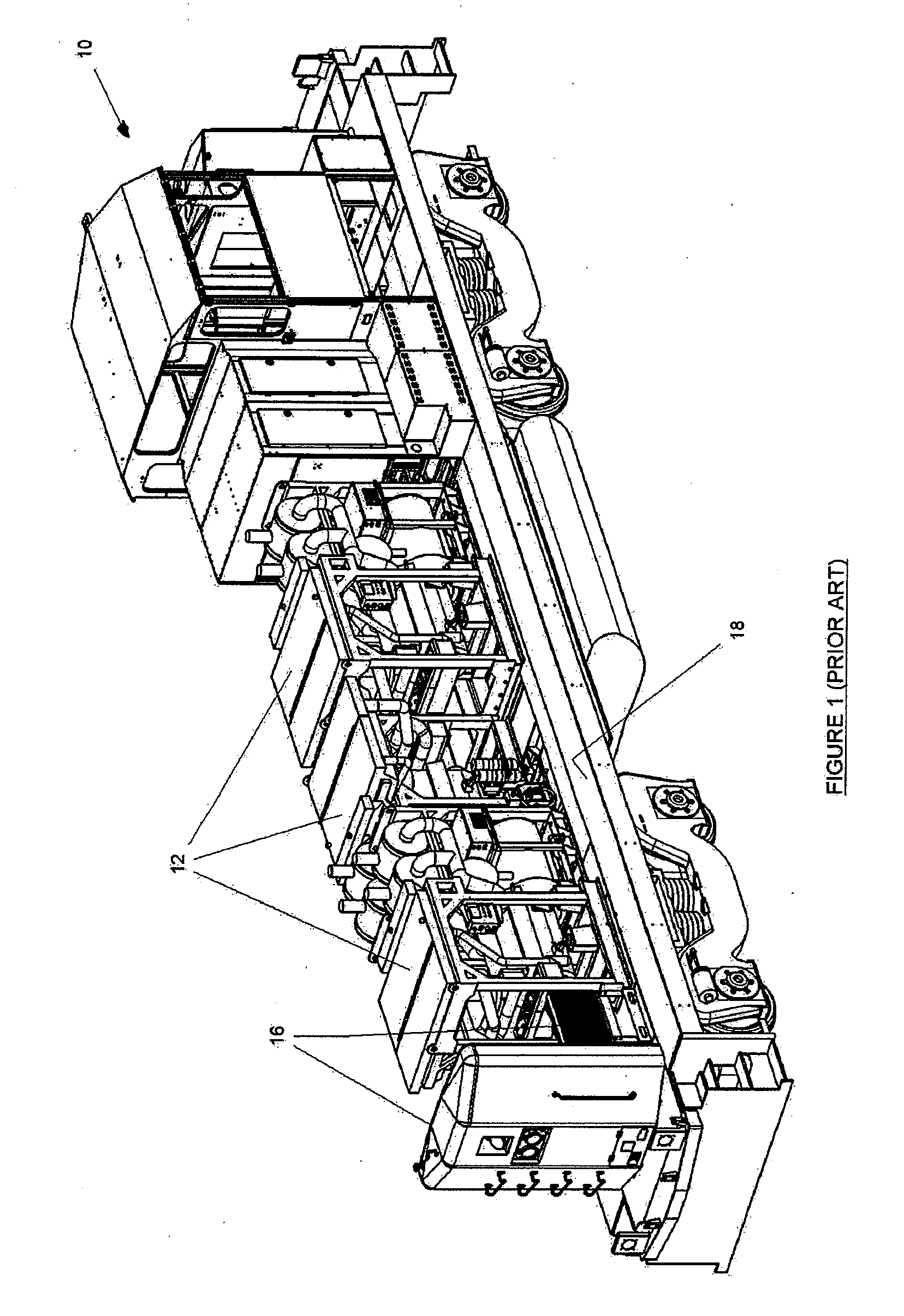

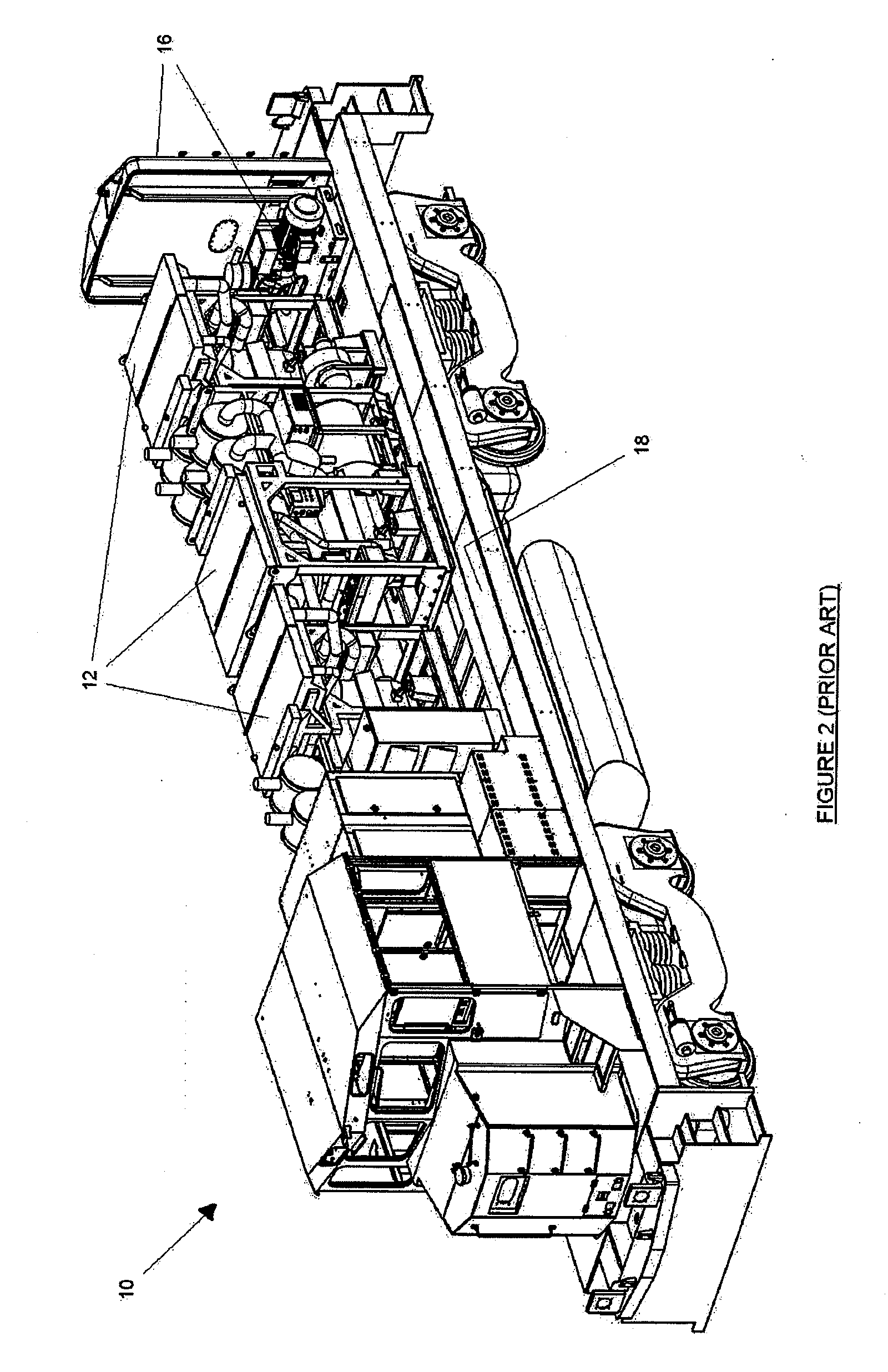

[0060]Referring to FIG. 4 for a schematic view and FIGS. 5-6 for exploded perspective views, the present invention provides a locomotive 30 comprising a platform deck 32 and a plurality of generator sets 34 on the platform deck 32, each generator set 34 occupying a space associated with a generally oblong footprint 36 on the platform deck 32, the footprint 36 defining a longitudinal axis along a longest length of the footprint 36. Each generator set 34 is positioned on the platform deck 32 such that the longitudinal axis of the corresponding footprint 36 is generally perpendicular to a direction of travel of the locomotive 30.

[0061]As explained previously, this layout of the generator sets on the platform has a number of advantages. A comparison of this transversal configuration of gensets with respect to prior art configurations is illustrated schematically in FIG. 4 and a summary comparison between the same three configurations is provided in the following table:

CriteriaActualTran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com