Valve timing controller

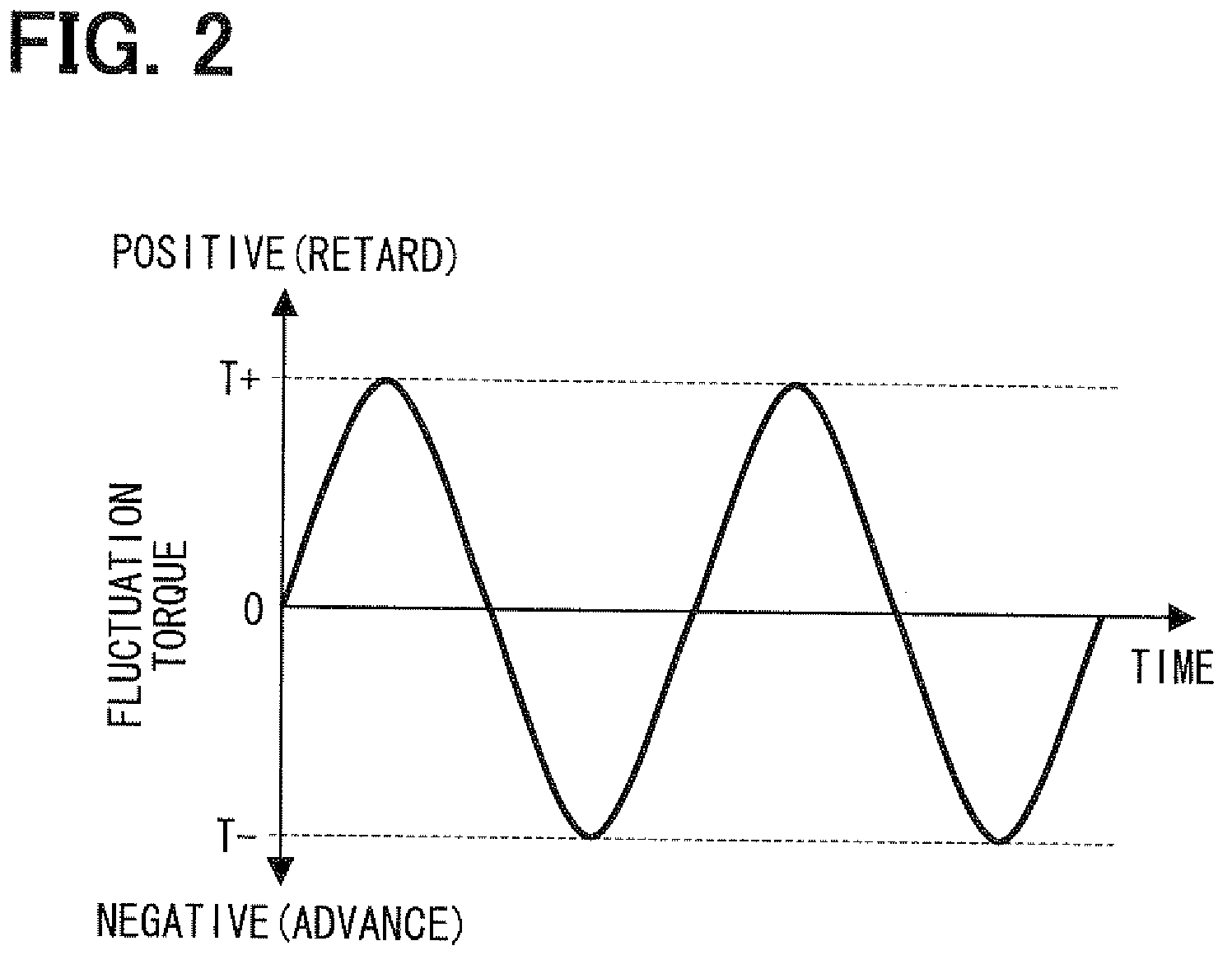

a timing controller and valve technology, applied in the direction of valve arrangements, machines/engines, mechanical equipment, etc., can solve the problems of deteriorating the control accuracy of the valve timing, large fluctuation of the vane rotor relative to the housing, etc., and achieve the effect of enhancing the variation speed of the engine rotational phase in a retarding direction and enhancing the engine rotational phase in an advance direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0027]Hereafter, the present invention is described.

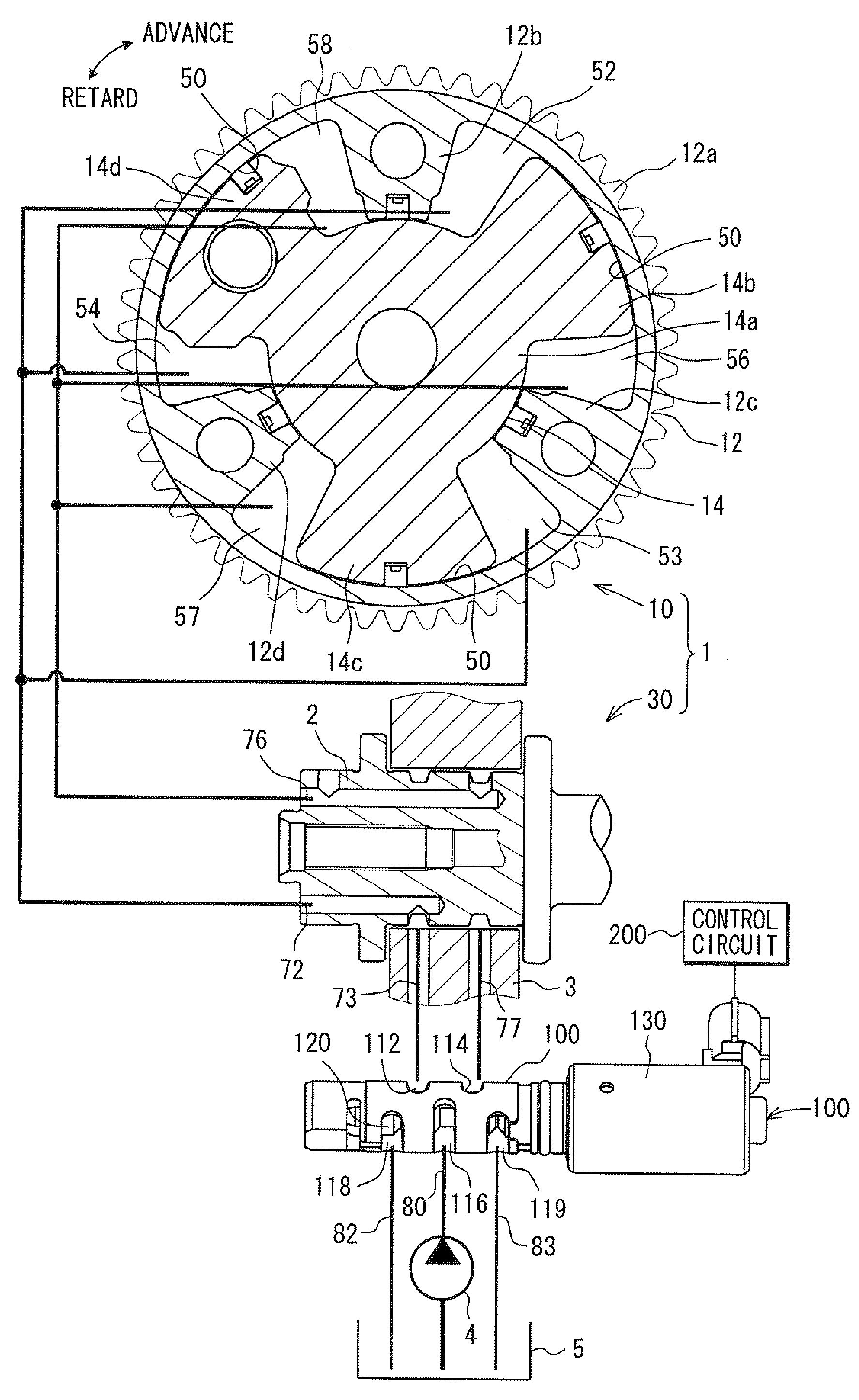

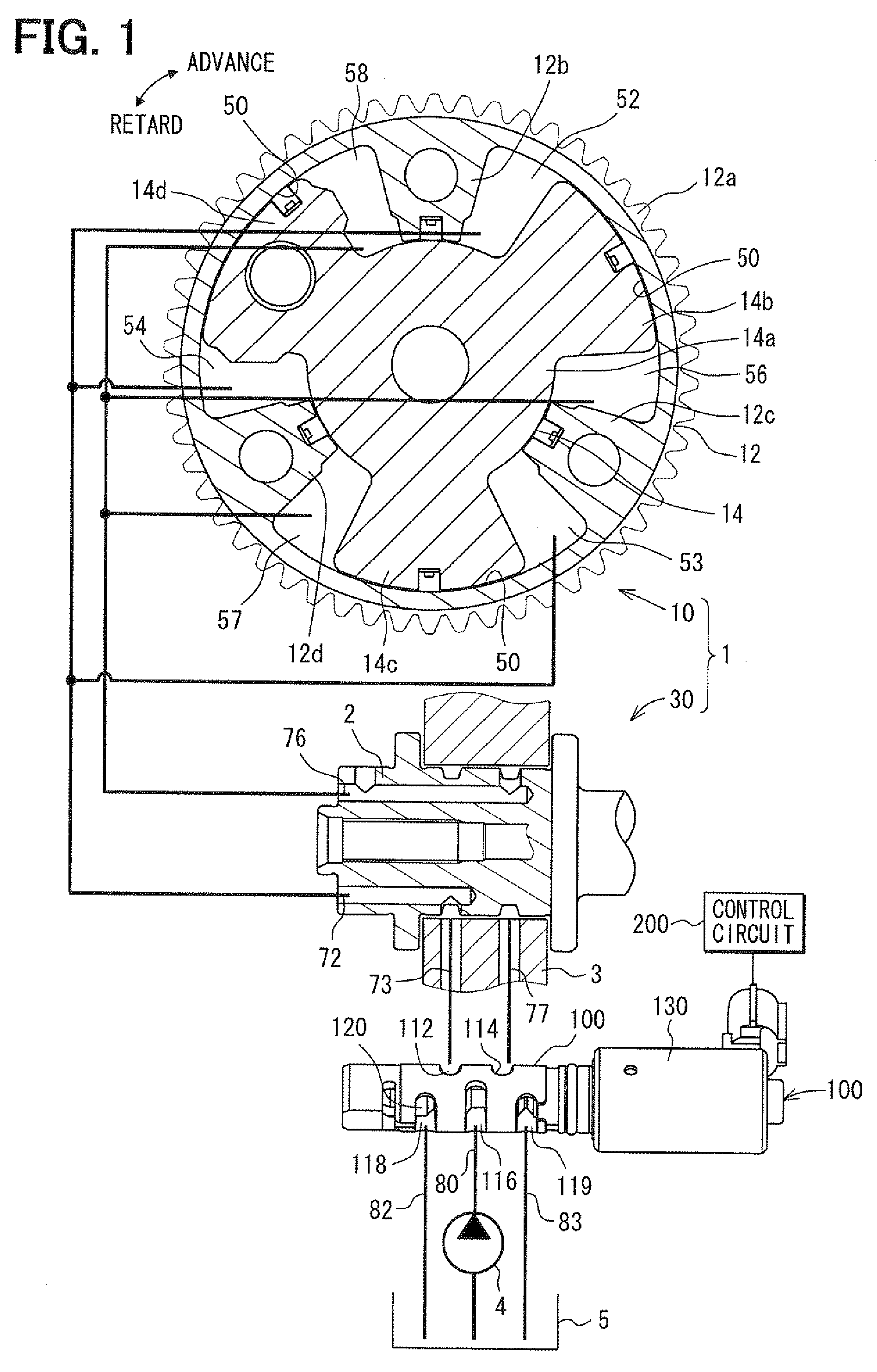

[0028]FIG. 1 shows a first embodiment of a valve timing controller 1 which is applied to an internal combustion engine for a vehicle. The valve timing controller 1 is driven by an operating fluid such as operating oil to adjust a valve timing of an intake valve.

(Basic Structure)

[0029]A basic structure of the valve timing controller 1 will be described hereinafter. The valve timing controller 1 includes a driving unit 10 and a control unit 30. The driving unit 10 transmits a driving force of a crankshaft (not shown) to a camshaft 2. The control unit 30 controls an operating oil supply to the driving unit 10.

(Driving Unit)

[0030]In the driving unit 10, a housing corresponding to a first rotating member includes a cylindrical sprocket 12a and a plurality of shoes 12b, 12c, 12d as partitioning portions.

[0031]The sprocket 12a rotates along with a crankshaft through a timing chain (not shown). While the engine is operated, the driving for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com