Electric cleaner

a vacuum cleaner and electric technology, applied in vacuum cleaners, vacuum cleaners, climate sustainability, etc., can solve the problems of limited size of detectable dust, difficult to determine the width of pulses with respect to large dust, and limited number of pulses of signal detection. achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0075]A first embodiment of the present invention is described as follows with reference to drawings.

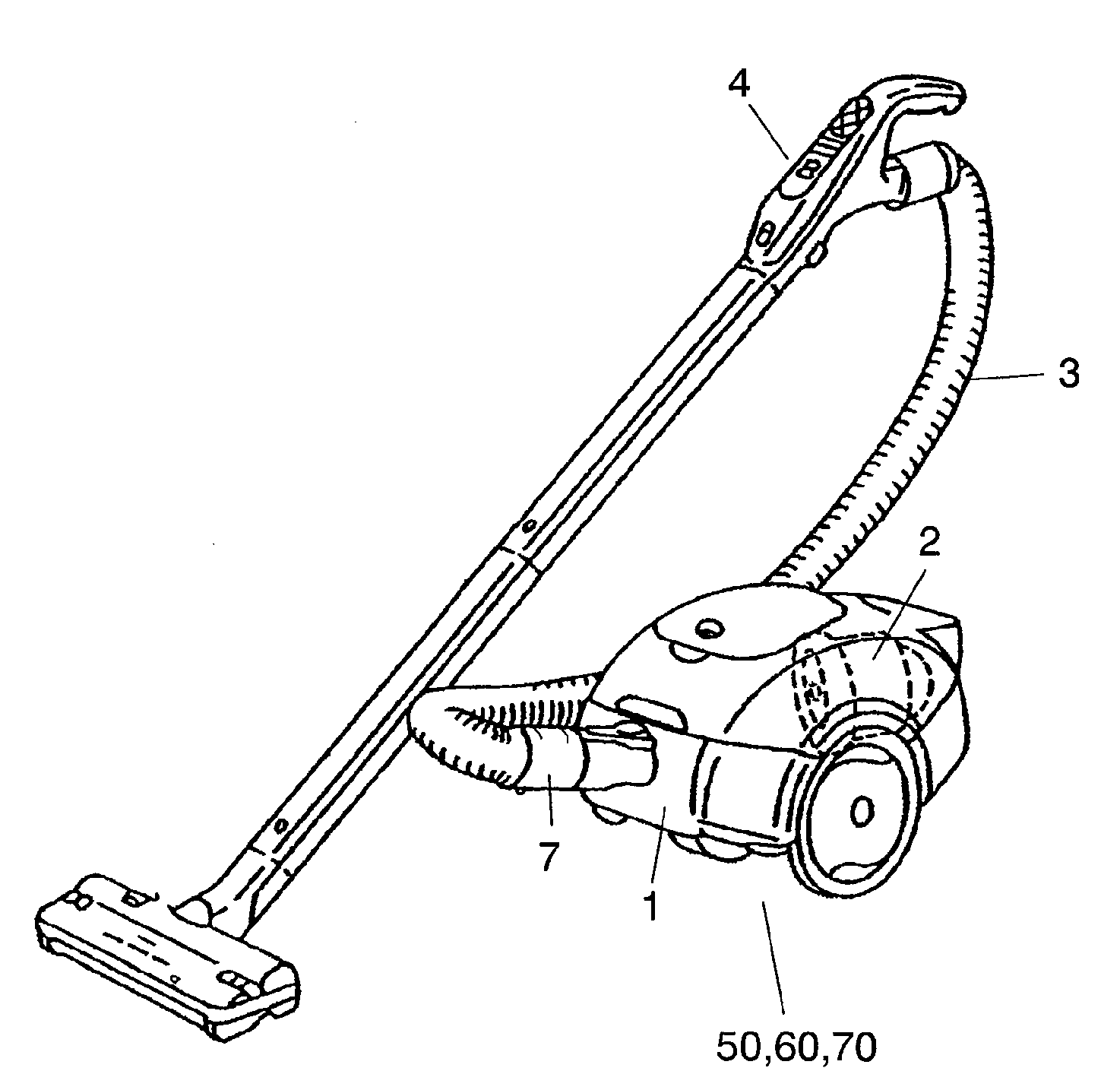

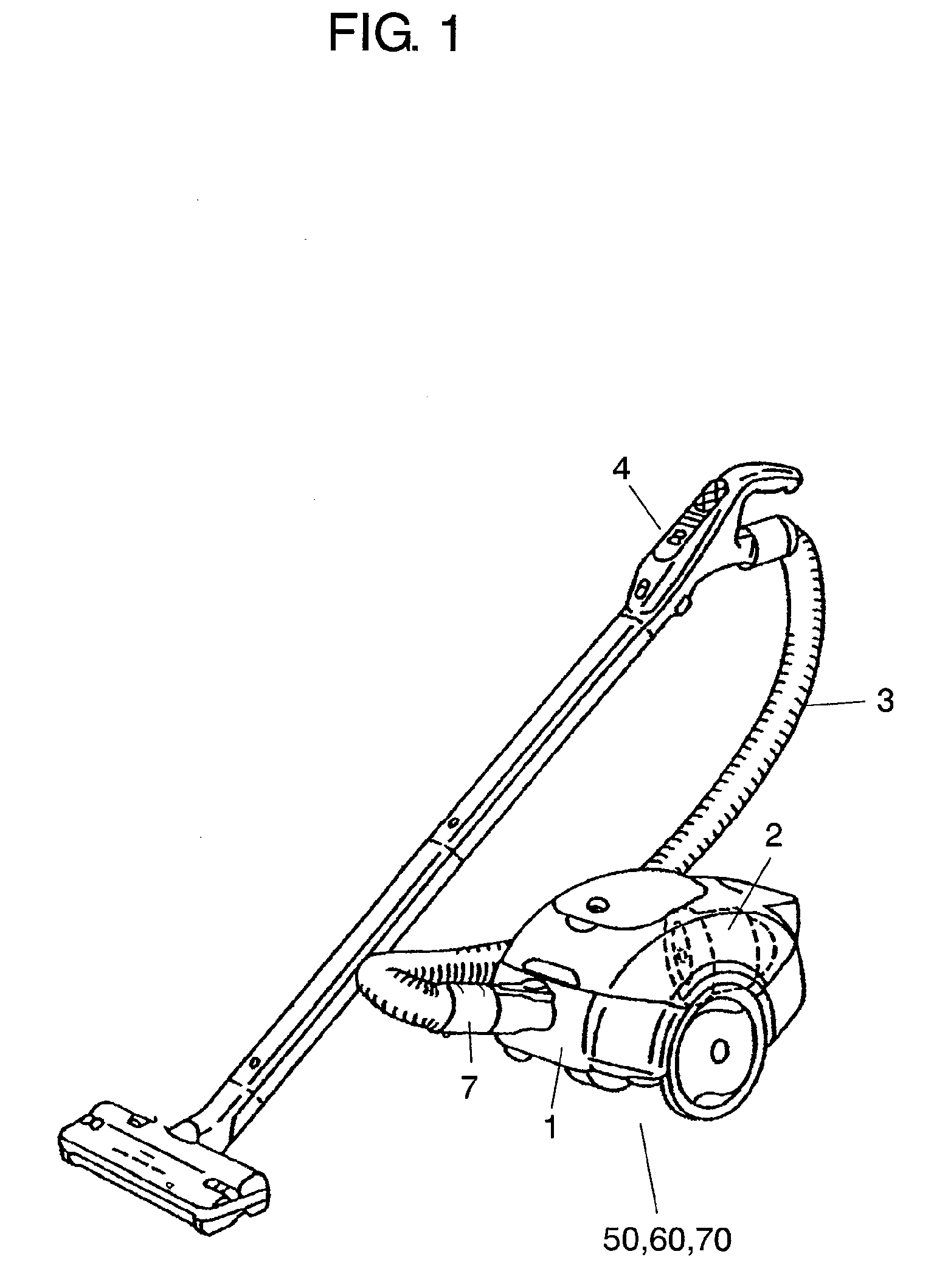

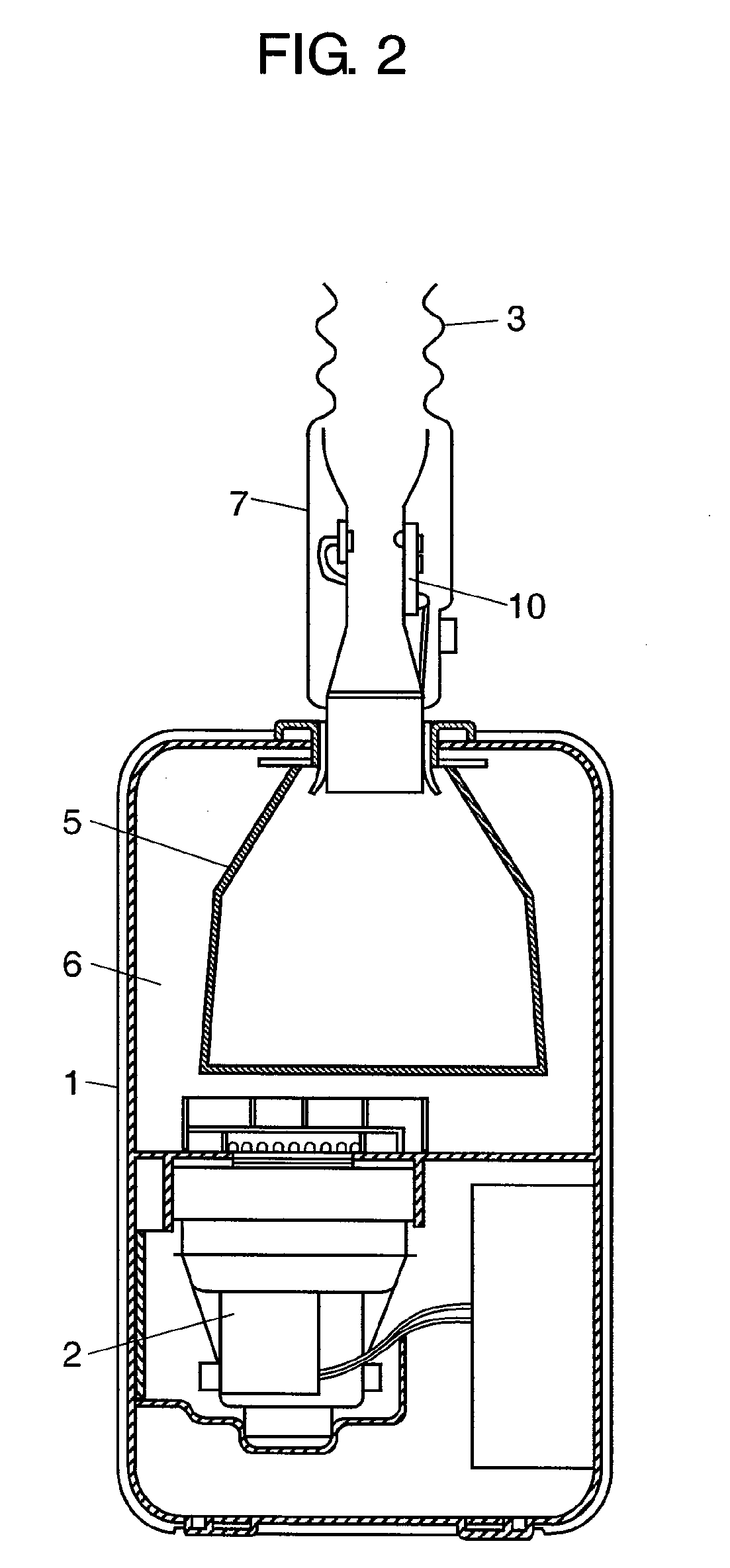

[0076]FIG. 1 is a perspective view of the appearance of electric vacuum cleaners 50, 60, and 70 according to the embodiments of the present invention. FIG. 2 is a schematic sectional view of electric vacuum cleaners 50, 60, and 70. Electric vacuum cleaner body 1 (hereinafter, body 1) houses electric blower 2 for generating suction power. Body 1 is connected to hose 3 having operating part 4 to be operated by the user. Body 1 further includes dust chamber 6 including dust bag 5.

[0077]Hose 3 includes dust detector 7 having first dust detector 10 and second dust detector 11 which will be described later. FIG. 3 is a schematic sectional view of dust detector 7 of the electric vacuum cleaners 50, 60, and 70.

[0078]FIG. 4 is a block diagram of the control system of electric vacuum cleaner 50 according to a first embodiment of the present invention. Body 1 includes driver 8 and determination...

second embodiment

[0115]A second embodiment of the present invention is described as follows with reference to drawings. FIG. 6 is a block diagram showing the control system of electric vacuum cleaner 60 according to the second embodiment. FIG. 7 is a flowchart showing an example of the dust detection signal processing of electric vacuum cleaner 60.

[0116]In the present embodiment, like components are labeled with like reference numerals with respect to the first embodiment, and the description of these components is not repeated.

[0117]Electric vacuum cleaner 60 includes first dust detector 40 having first amplifier-determiner 32 and second dust detector 41 having second amplifier-determiner 33. First dust detector 40 and second dust detector 41 are each composed of a transistor and one of a Zener diode and a resistor. First and second dust detectors 40 and 41 output signals whose voltages are changed to a plurality of voltage levels, thereby transmitting them as detection signals to dust amount senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com