Pneumatic adjustable sanding device

a sanding device and pneumatic adjustment technology, applied in metal-working equipment, portable grinding machines, manufacturing tools, etc., can solve problems such as fairly complex mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

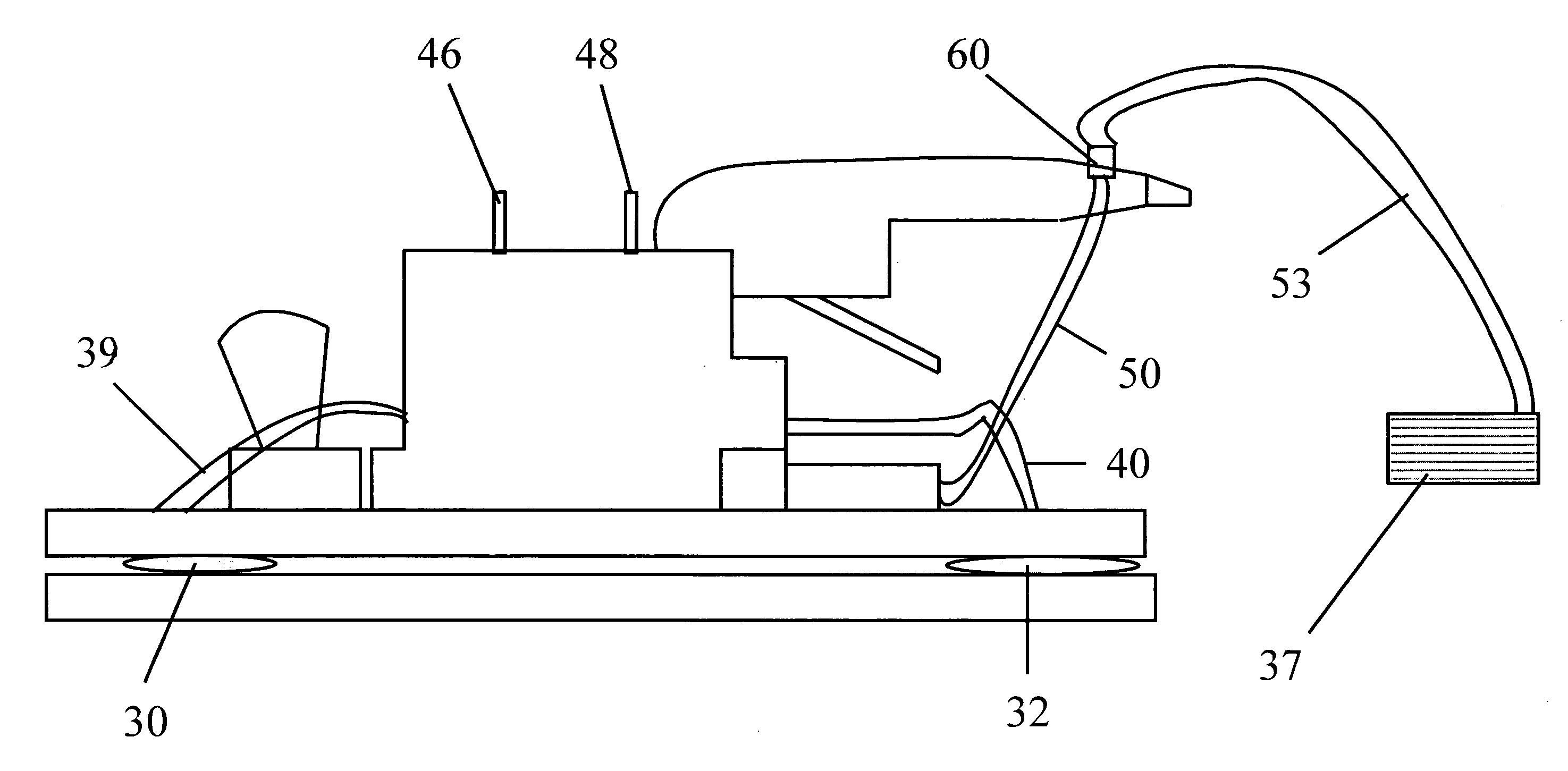

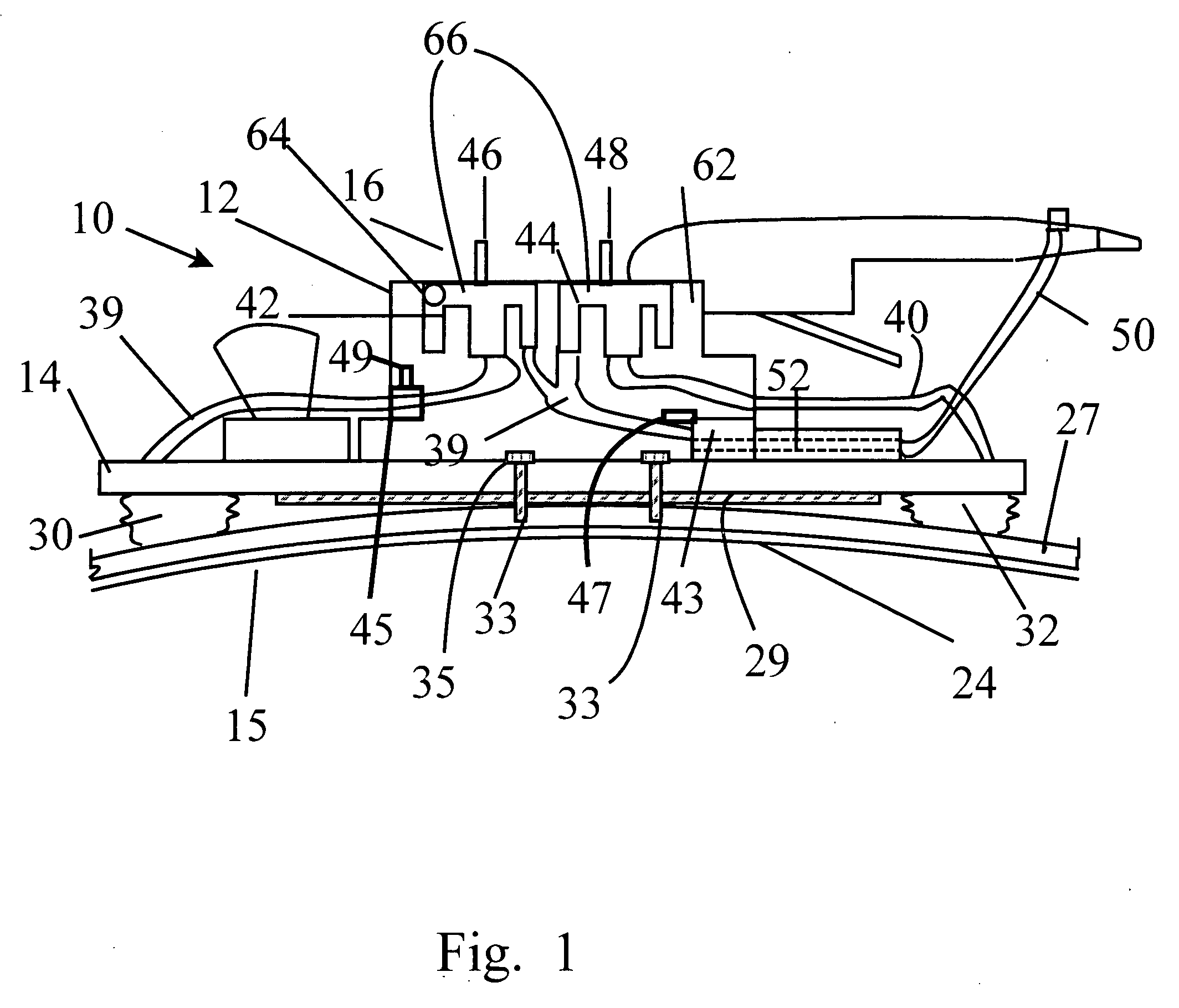

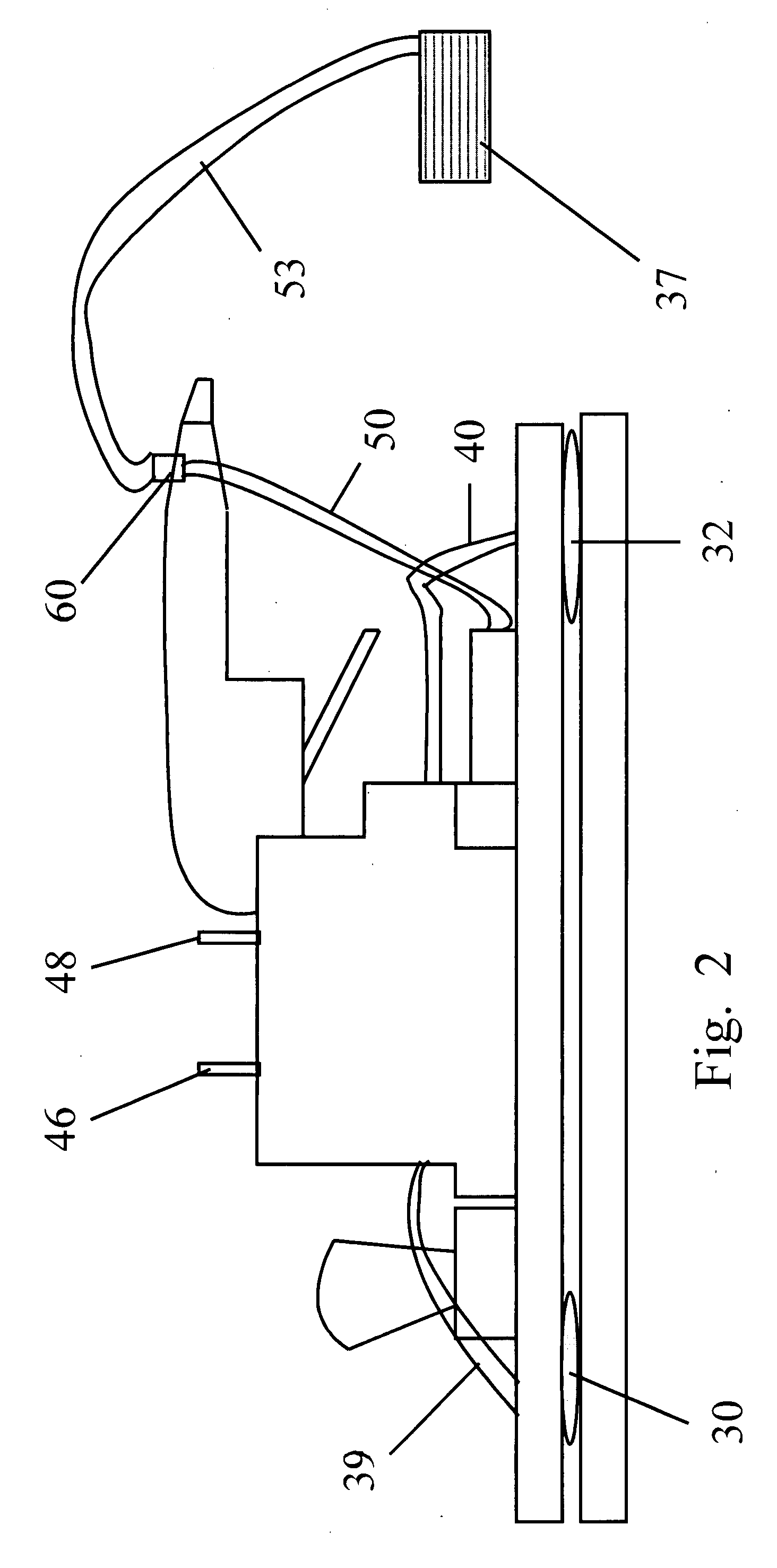

[0022]Referring now to FIGS. 1-4C, a sanding and abrading machine attachment integrated with a standard sanding and abrading machine is shown. The attachment, generally indicated by the numeral 10, is adapted for use with a handheld pneumatic or other powered sander 12 having a flat bed 14 which is moved in a longitudinal or orbital path at a relatively high speed. These sanders 12 typically have only a single flat bed 14 with means such as clamps etc. for selectively releasing / securing strips of sanding or abrading material to be applied to a workpiece. Sanding or abrading contoured surfaces is typically done with some difficulty even by professionals, the results obtained thereby are not always satisfactory, and even in the event they are, much time is consumed in the process. To that end, the attachment 10 of the present invention is provided to facilitate sanding of contoured surfaces with superior results while minimizing the time spent by the worker.

[0023]The attachment 10 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com