Vacuum Dust Collector

a vacuum cleaner and dust collector technology, applied in vacuum cleaners, household cleaners, tableware washing/rinsing machines, etc., can solve the problems of easy fluttering of dust in the air, user discomfort, easy for users, etc., and achieve the effect of occupying spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

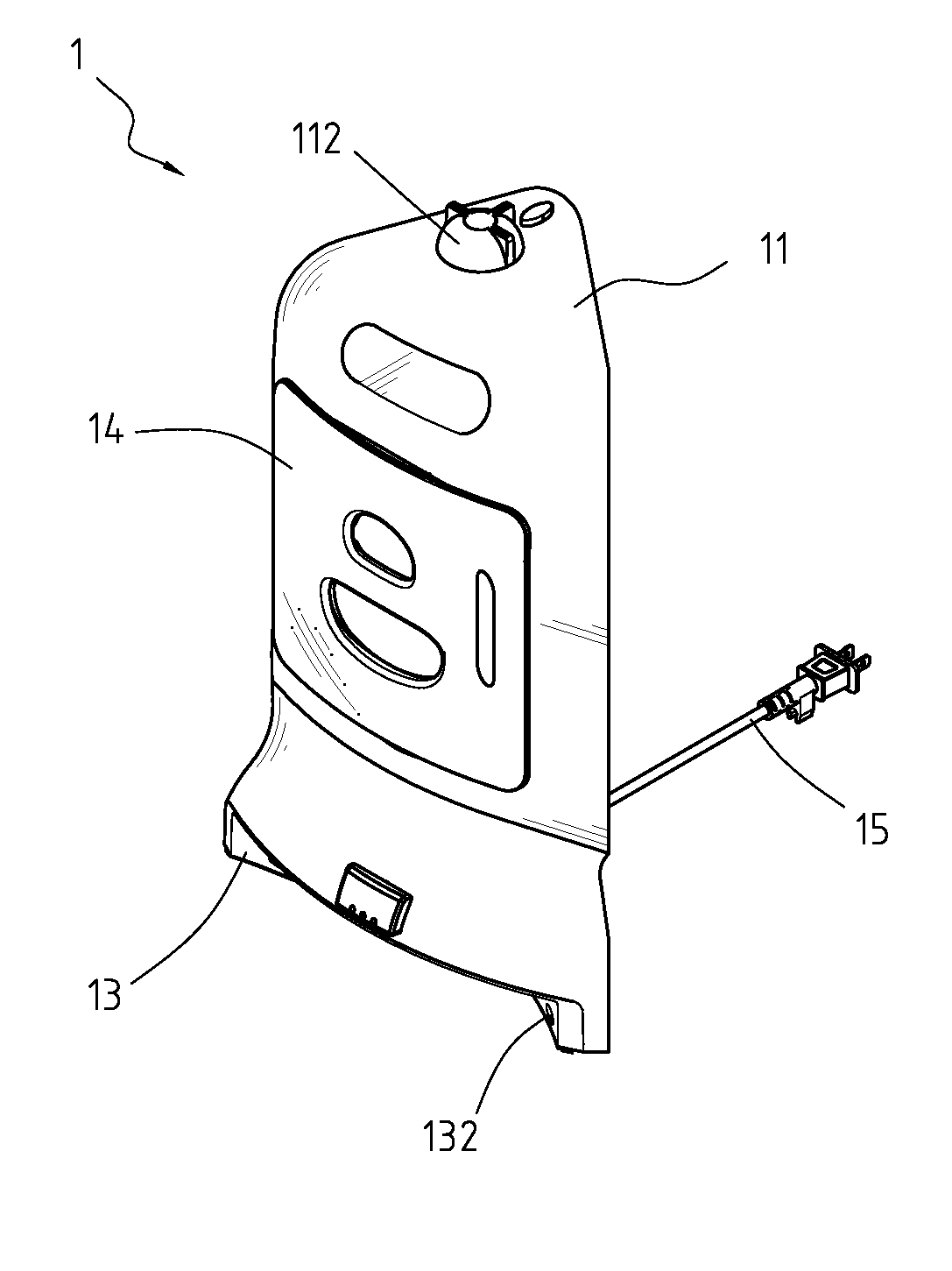

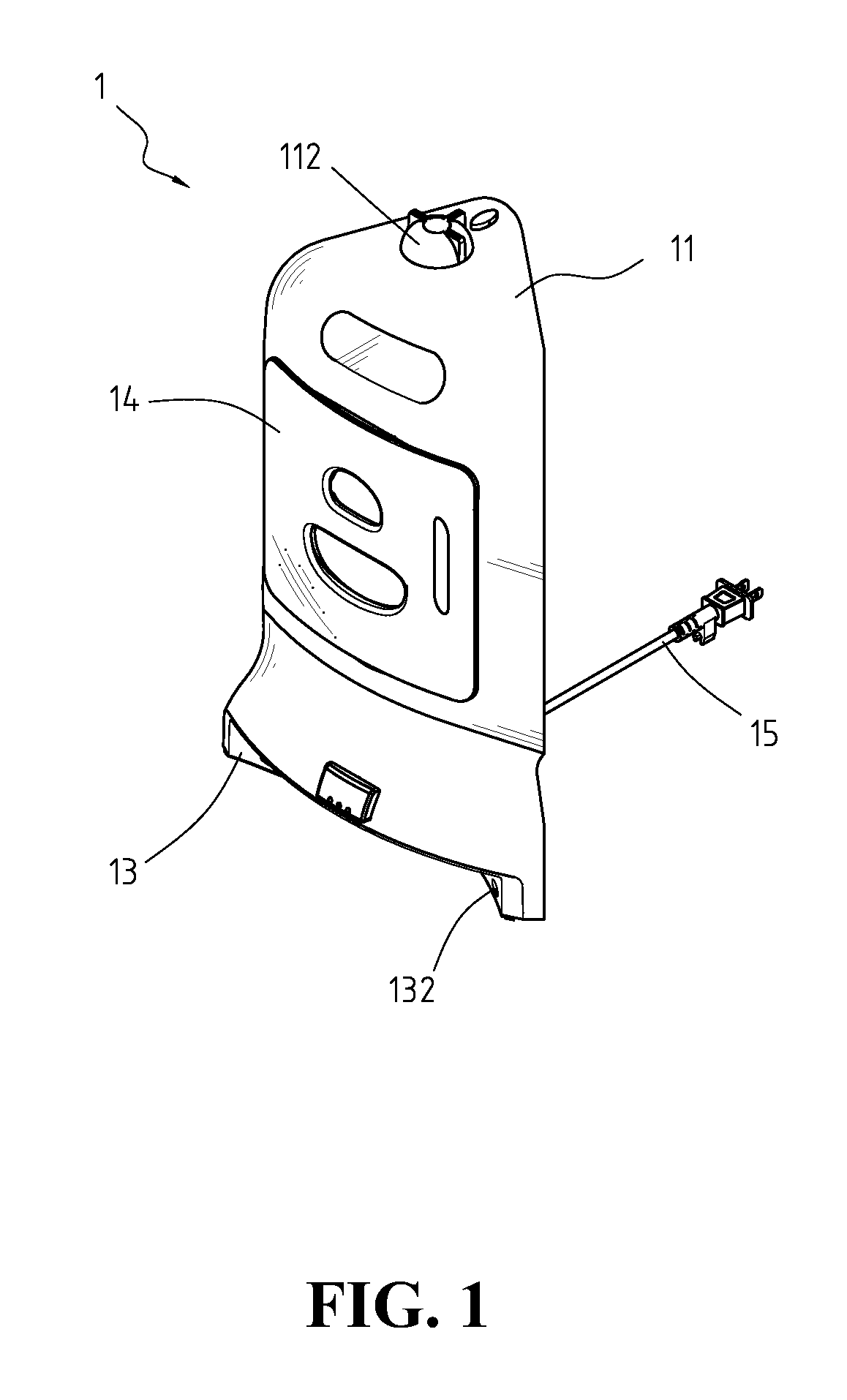

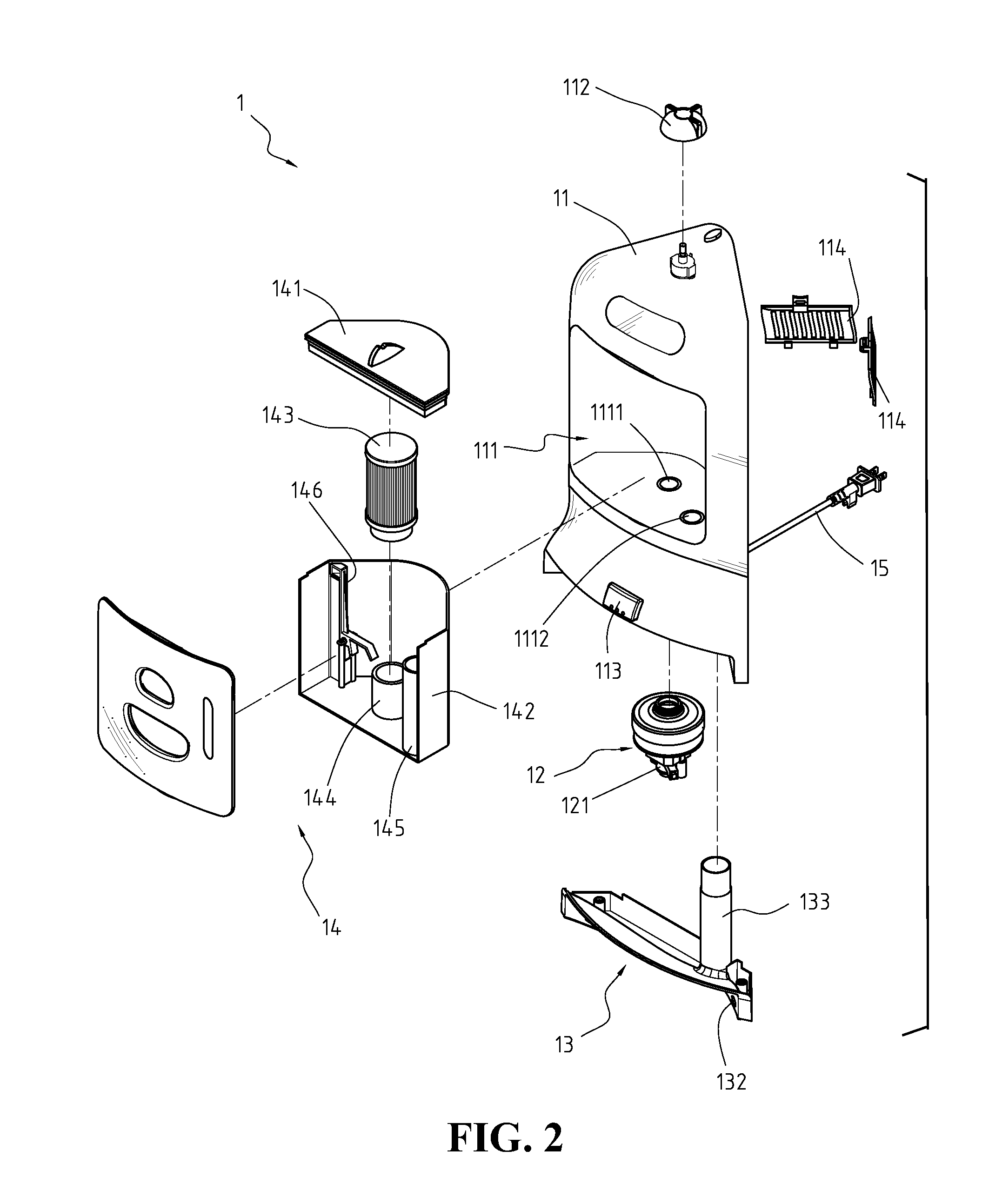

[0023]Referring to FIG. 1 and FIG. 2, illustrates the perspective view and the exploded view of the present invention, respectively. A vacuum dust collector 1 comprises a housing 11, a suction generator 12, a bottom cover 13, a dust container 14 and a power cord 15, wherein the housing 11 includes a concaved space 111, a control knob 112, an outlet port 1111 and an inlet port 1112 mounted in the bottom of the concaved space 111. The control knob 112 is set on the top surface of the housing 11 and electrically connected to the suction generator 12. In addition, the control knob 112 is used to switch the operation mode of the vacuum dust collector 1.

[0024]Furthermore, there is a suction side and an exhausted side in the suction generator 12 placed under the concaved space 111 of the housing 11. The suction generator 12 is connected to the outlet port 1111 of housing 11 by the suction side. Subsequently, the suction generator 12 includes a motor 121 and a fan (unshown). The motor 121 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com