Panelling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

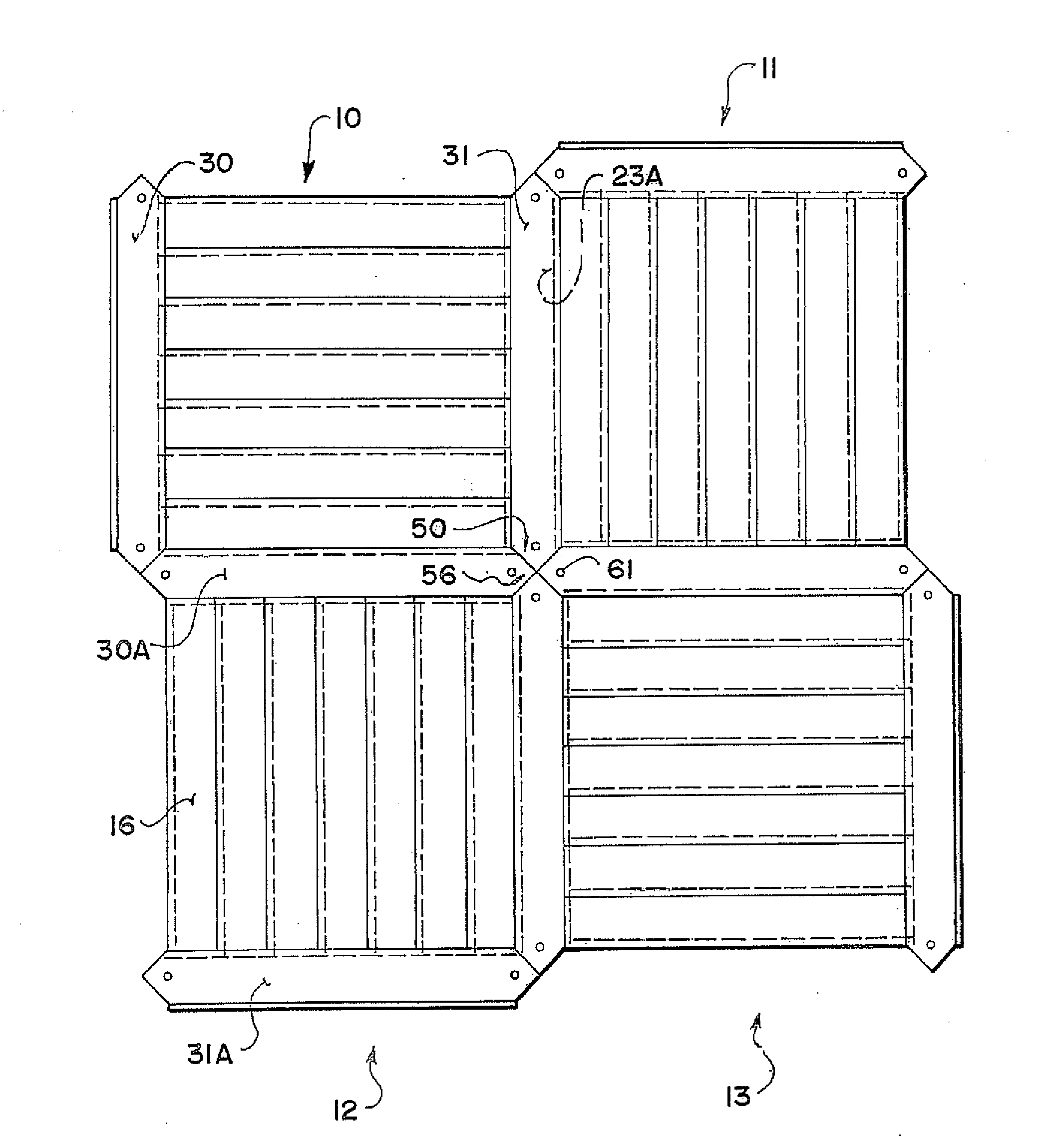

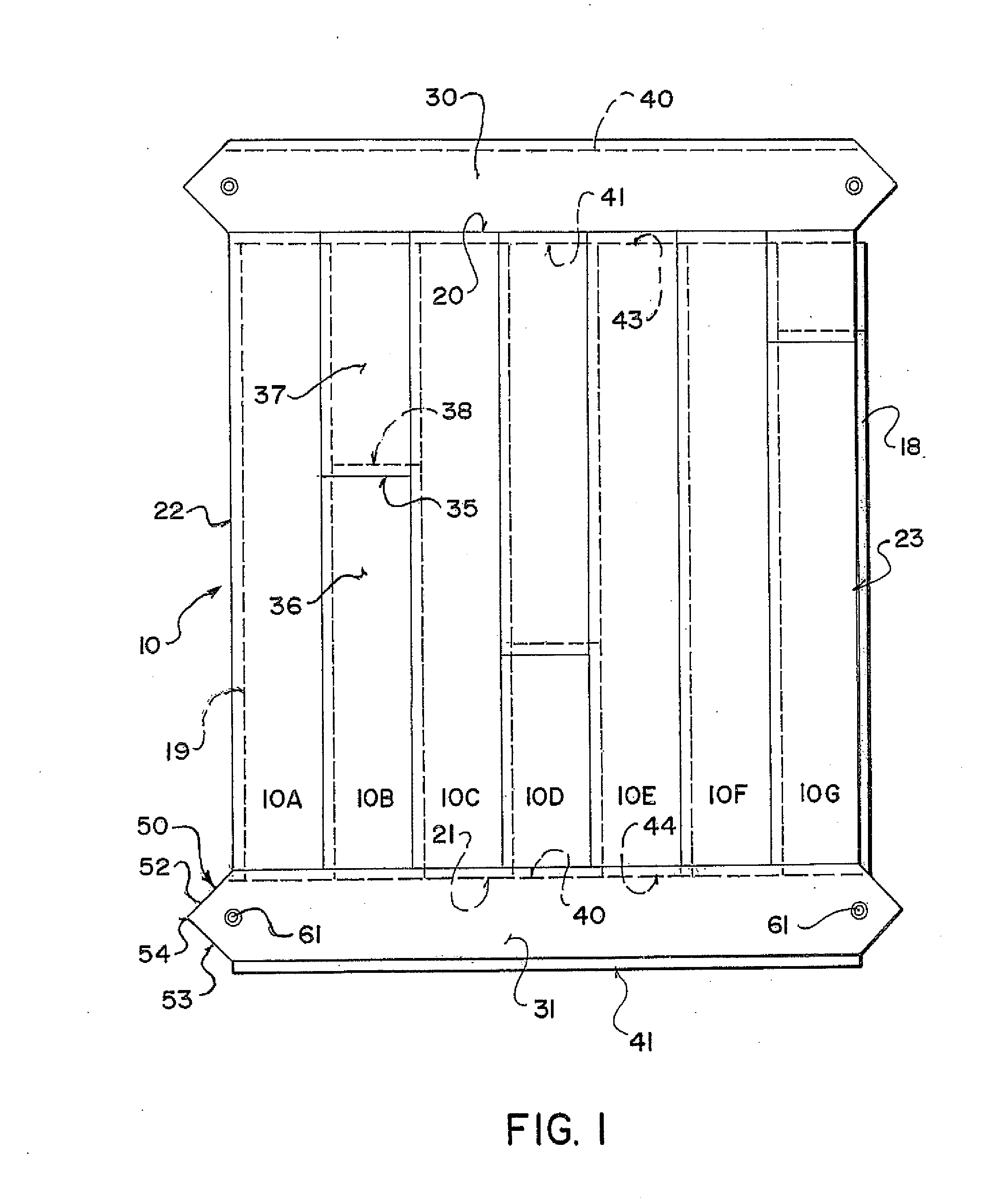

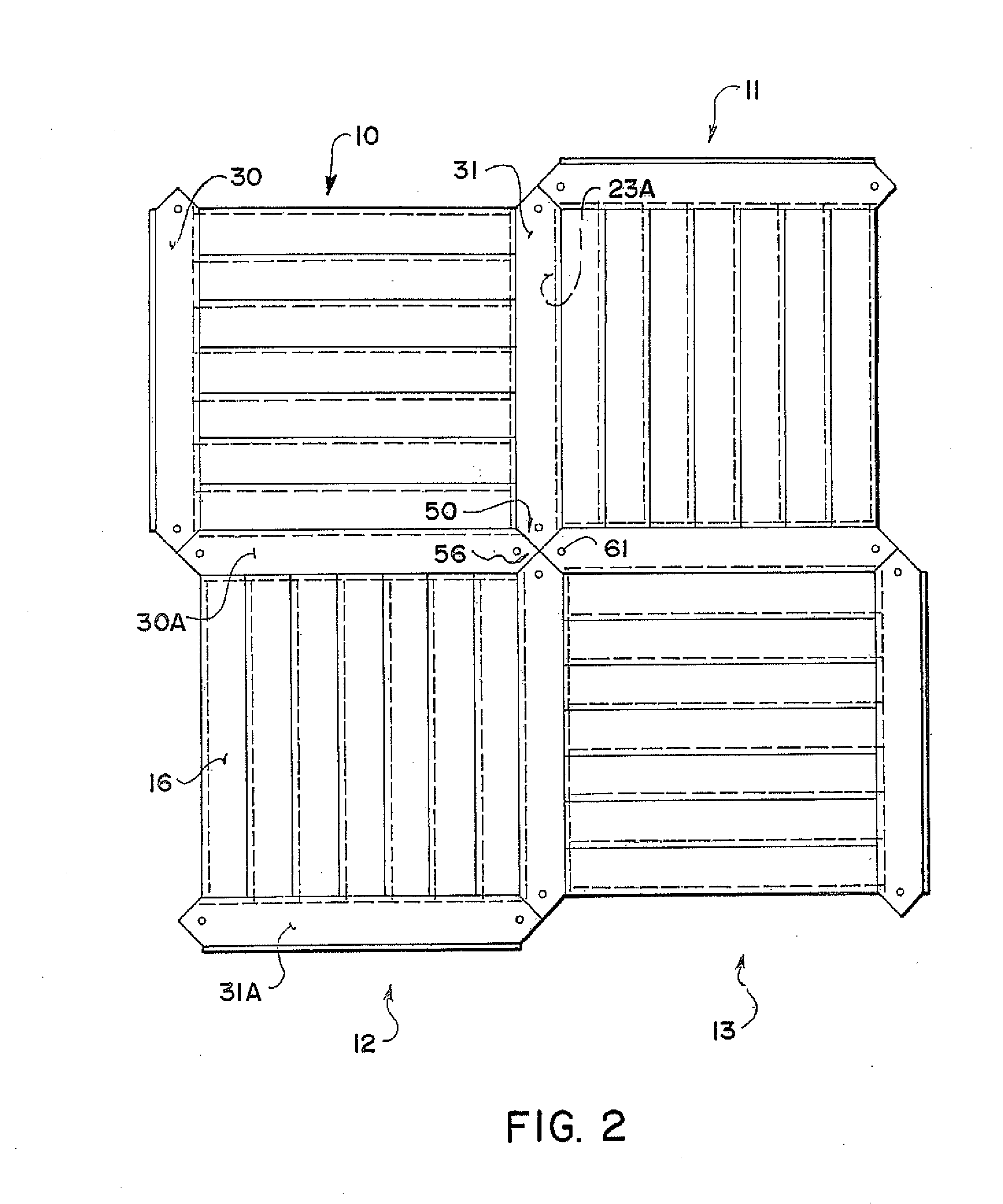

[0042]Reference is made to the above published application of Gibson which shows and describes the details of the panels with the dividing strips and the interconnection between the four corners of the panels.

[0043]The arrangement described herein comprises a floor system defined by a series of panel members, four of which are shown at 10 through 13. Each of the panel members has a top surface 16 defining a floor surface on which the user walks and providing an attractive appearance as described hereinafter. Each of the panel members includes a bottom surface 17 for sitting on a sub floor of a conventional nature.

[0044]Each of the panel members is formed from a plurality of side by side main strips 10A to 10G which are connected together side by side to form an initial panel portion which has four side edges so that for example the panel 10 has side edges 20 and 21 which form a first pair of opposed side edges and side edges 22 and 23 which form a second pair of opposed side edges.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com