Hinge lid container

a lid container and hinge technology, applied in the direction of lids, non-removable lids/covers, packaging, etc., can solve the problems of limited visible exterior surface area and small size of standard hinge lid cigarettes packs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

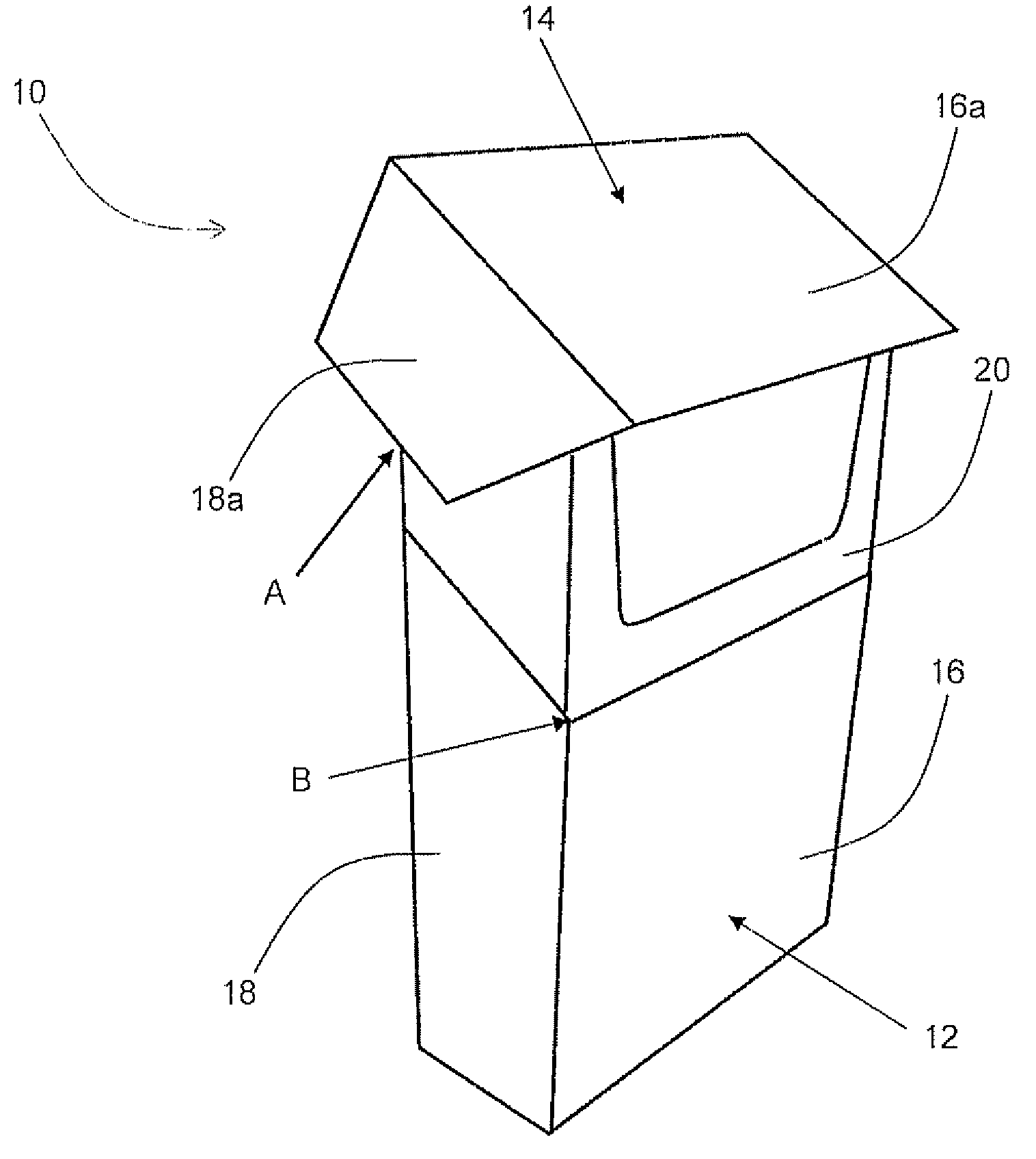

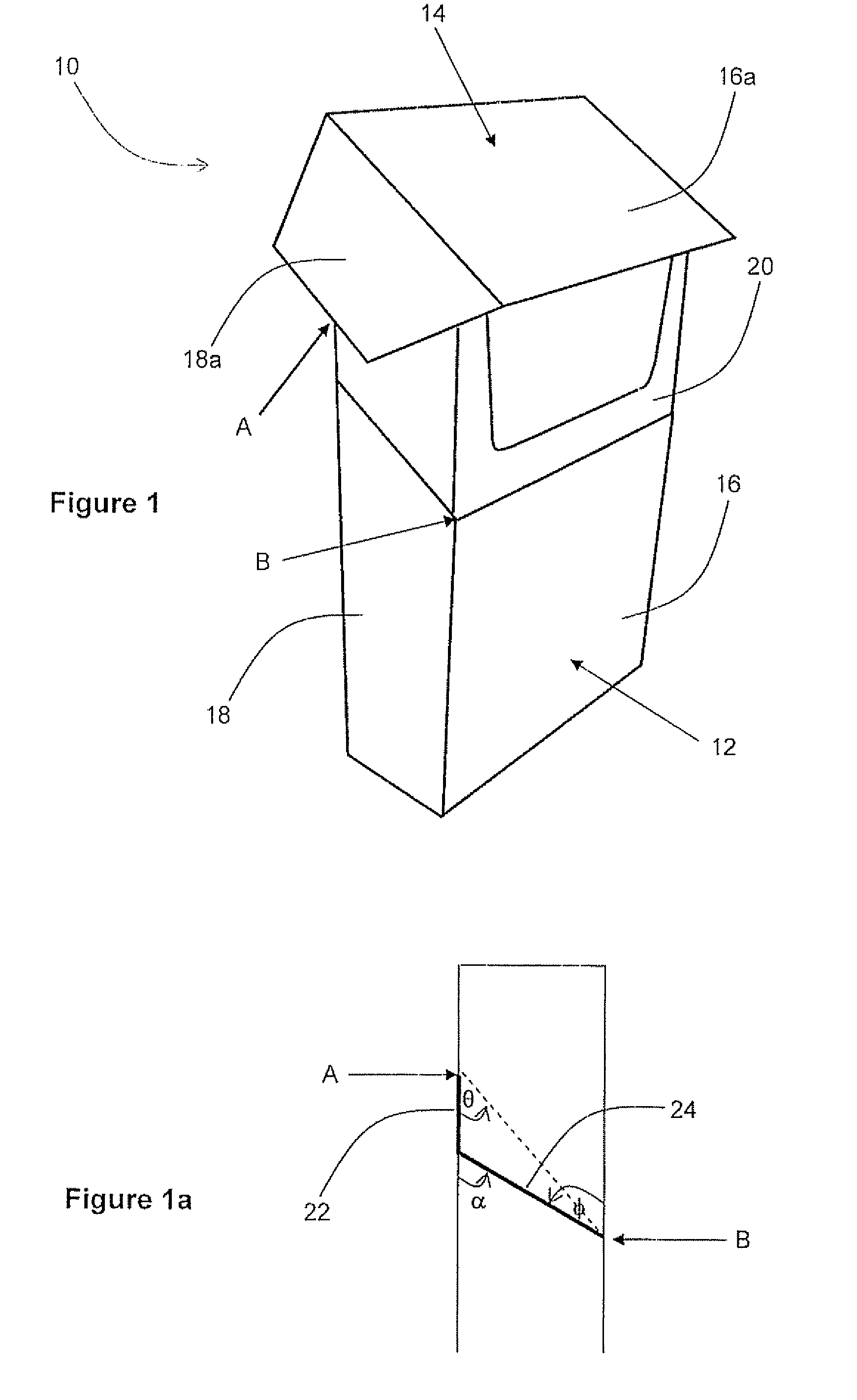

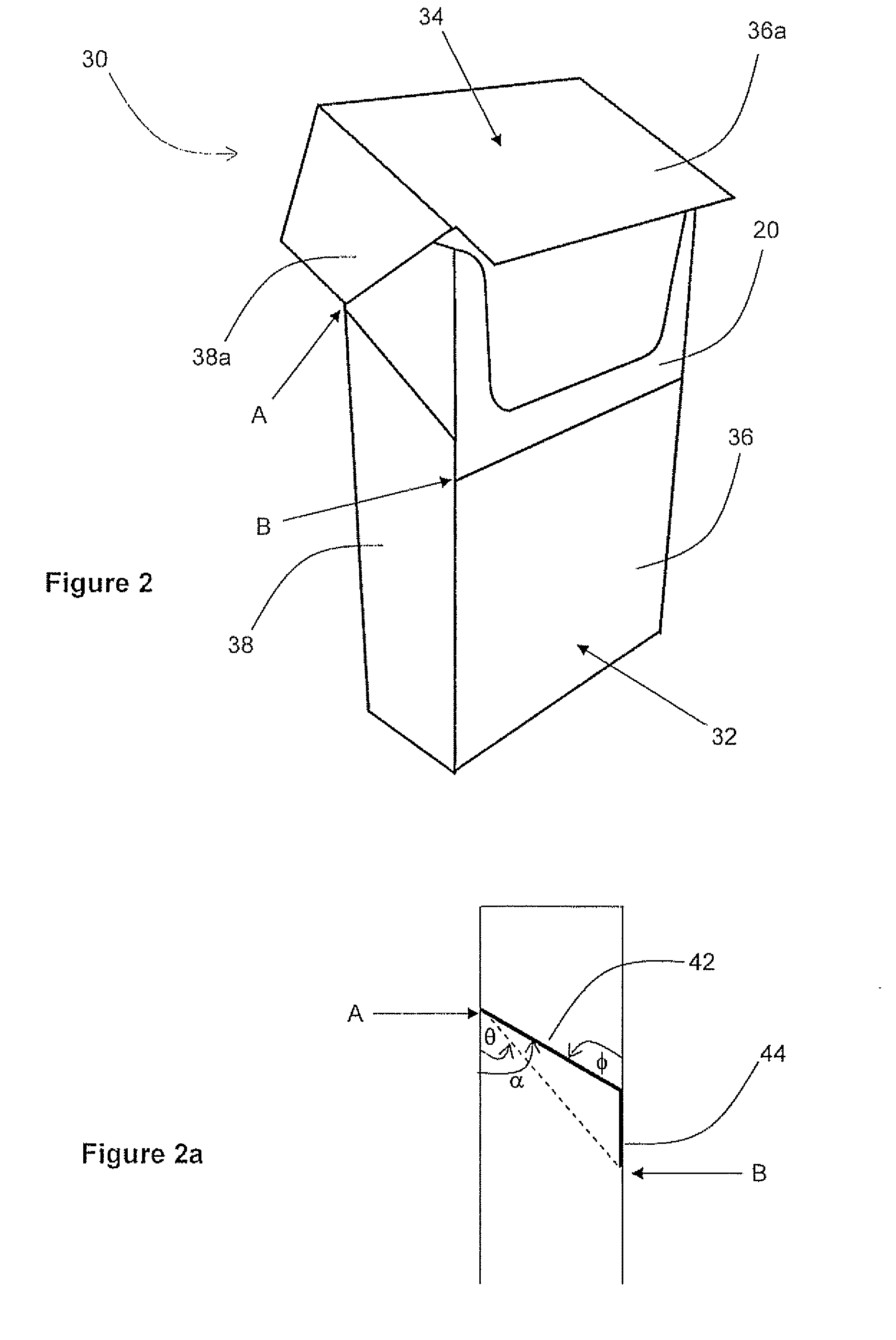

[0045]The hinge lid container 10 shown in FIG. 1 is a rectangular parallelepiped and comprises a lower box portion 12 and an upper lid portion 14 that is hinged to the lower box portion 12 along a hinge fine extending substantially horizontally along the rear wall of the container. The level of the hinge line is indicated in FIG. 1 at point “A”.

[0046]The box portion 12 has a front wall 16, a left side wall 18, a right side wall, a rear wall, and a bottom wall. The rear wall of the box portion 12 extends above the side walls thereof so that the upper edge of the rear wall is offset from the upper free edges of the side walls. The upper edge of the rear wall of the box portion is defined by the hinge line.

[0047]The lid portion 14 has a front wall 16a, a left side wall 18a, a right side wall, a rear wall and an upper wall. The side walls 18a of the lid portion extend beyond the rear wall thereof so that the lower free edge of each side wall is offset from the lower edge of the rear wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com