Method and System for Helicopter Portable Drilling

a portable drilling and helicopter technology, applied in the field of methods and systems for drilling, can solve the problems of high risk for pilot and driller, unfavorable safe landing, and high risk of pilot and driller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

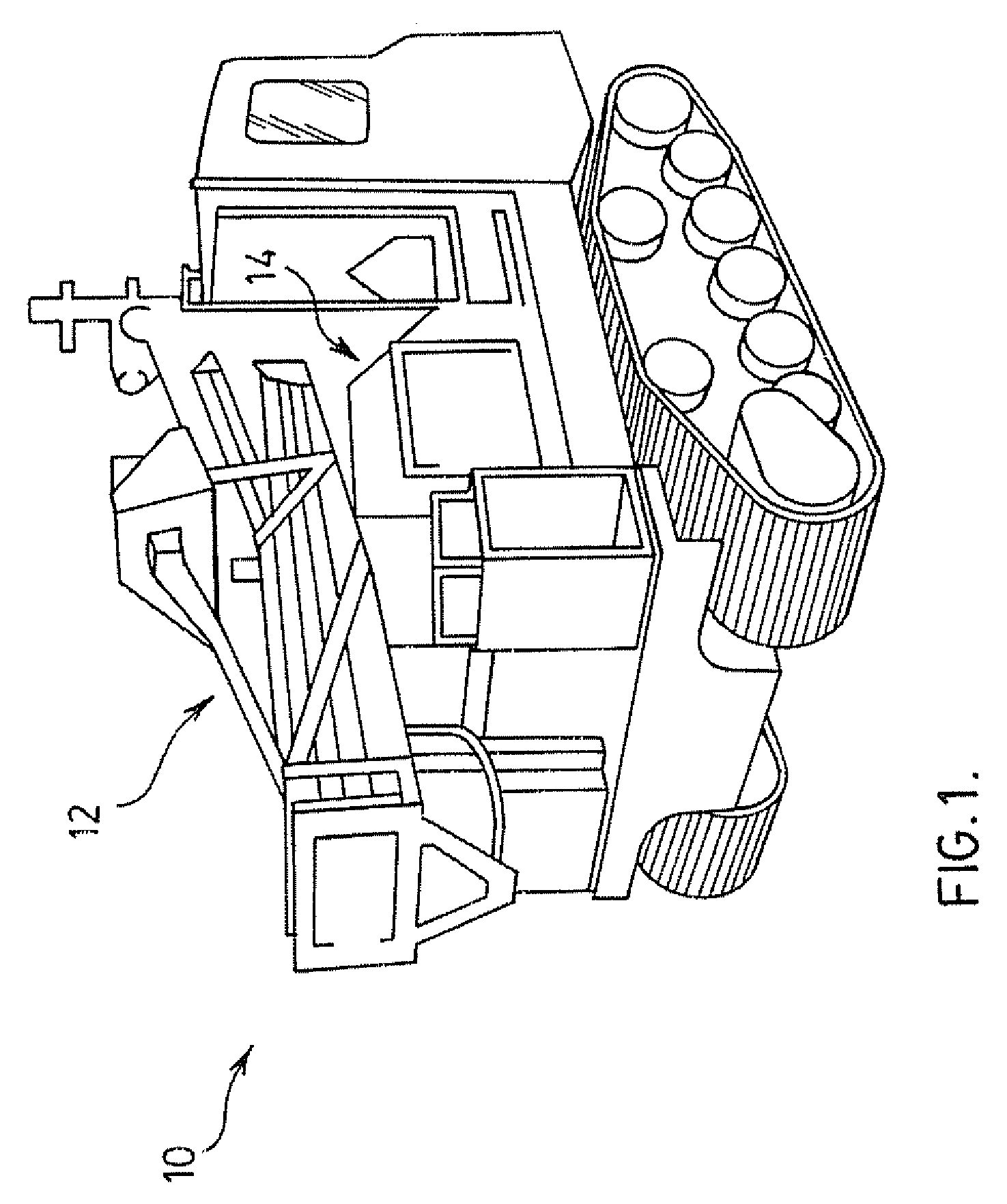

[0047]Referring to FIG. 6 there is illustrated in a right side view a single pick drilling system in accordance with an embodiment of the present invention. The single-pick drilling system 100 includes a drill frame 102, a drill mast 104, a combined power source, compressor and hydraulic pump 106. The single-pick drilling system 100 also includes a fuel tank 108, hydraulic tank 110 (110 not seen in drawing 100, a detonator magazine 112, an explosives magazine 114, loading poles 116, drill stems 118 and air and oil separator 120. The drill frame 102 stands on four adjustable legs 122.

[0048]Referring to FIG. 7 there is illustrated in a right front perspective view the single-pick system of FIG. 6. FIG. 7 shows the driller's station 124 with hydraulic and pneumatic controls. Hydraulic tank 110 is in bottom right corner under drill stem 118.

[0049]Referring to FIG. 8 there is illustrated in a left side view the embodiment of FIG. 6. FIG. 8 shows the detonator magazine 112, the explosives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com