Method for producing retardation film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 3

Producing Example 3

[0107]A laminated film 3 being 1350 mm in width and 180 μm in thickness composed of the polycarbonate resin layer (layer A: 10 μm) and the styrene maleic anhydride copolymer resin layer (layer B: 170 μm) was obtained in the same manner as in PRODUCING E EXAMPLE 1, except that the thickness of layer A Was adjusted to 10 μm and the thickness of layer B was adjusted to 170 μm.

example 4

Producing Example 4

[0108]A laminated film 4 being 1350 nom in width and 180 μm in thickness composed of the polycarbonate resin layer (layer A: 80 μm) and a polystyrene resin layer (layer B: 90 μm) was obtained in the same manner as in PRODUCING EXAMPLE 1, except that the polystyrene resin (made by Japan Polystyrene Inc., HF44, a deflection temperature under load is 73° C.) was used in place of Dylark D332, the thickness of layer A was adjusted to 80 μm and the thickness or layer B was adjusted to 90 μm.

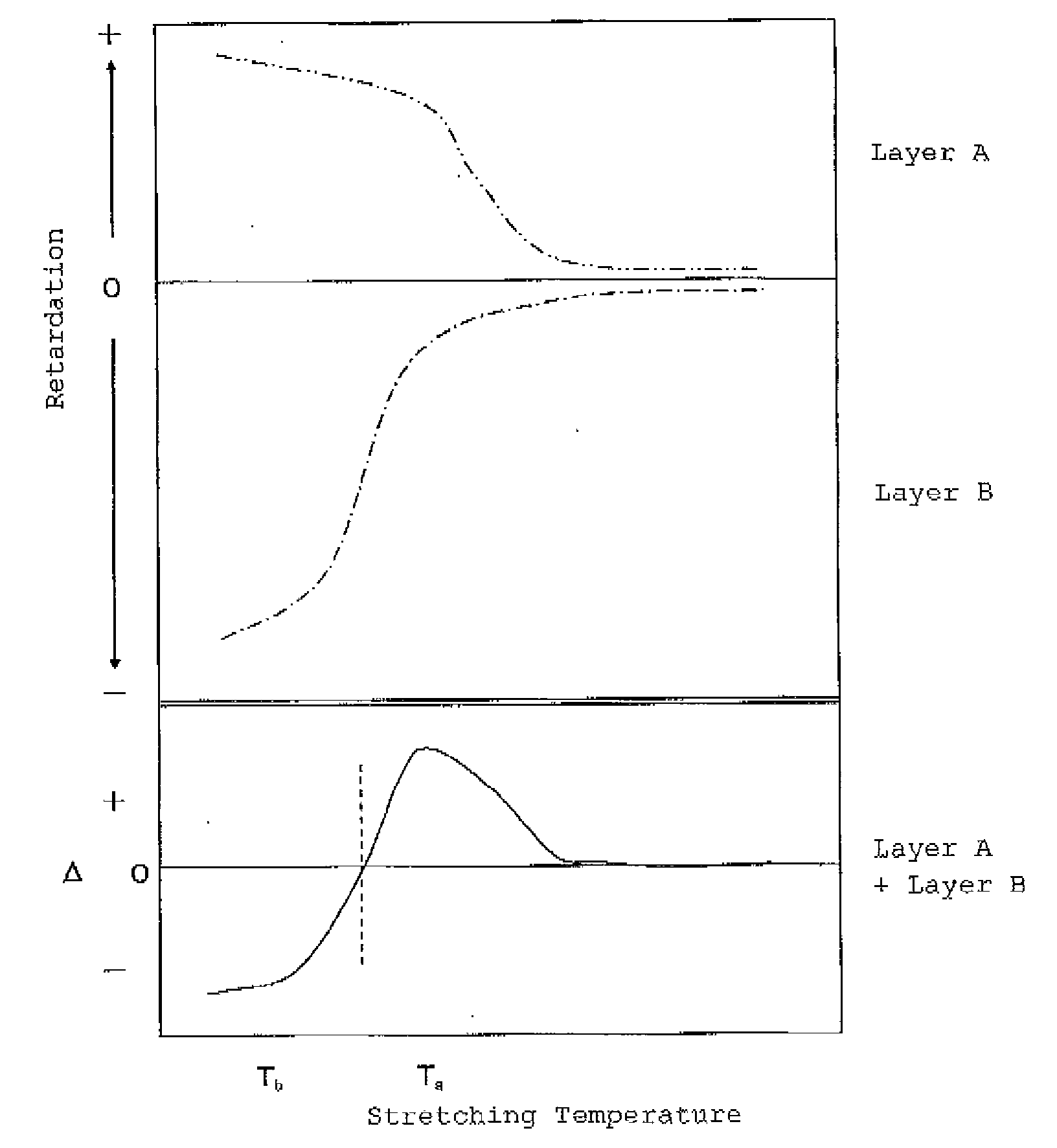

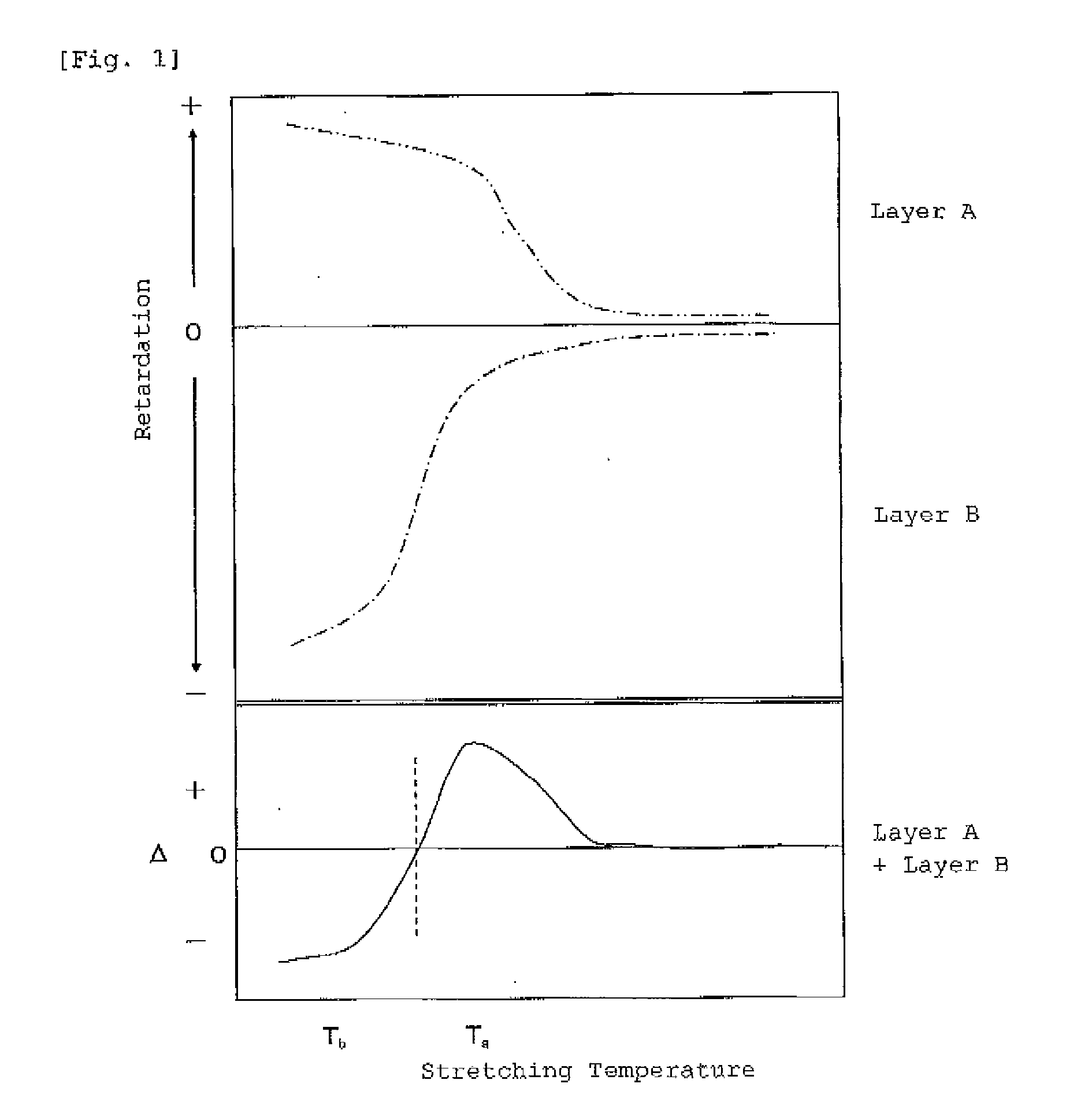

[0109]The laminated films 1 to 4 were uniaxially stretched by 1.25 times of stretching ratio in various temperatures in a longitudinal direction of the film, Table 1 shows the lag in a phase of which linearly polarized light entering vertically into the film plane and having an oscillating surface of an electric vector in an X-Z plane against linearly polarized light entering vertically into the film plane and having a oscillating surface of an electric vector in a Y-Z plane, in whic...

example 1

[0111]The laminated film 1 obtained in PRODUCING EXAMPLE 1 was supplied to a longitudinal uniaxially stretching machine, and the film was stretched in a longitudinal direction at a stretching temperature of 145° C. by a stretching magnification of 1.5 times.

[0112]Then, the stretched film was supplied to the tenter stretching machine, the film was stretched in a transverse direction at a stretching temperature of 130° C. by a stretching magnification of 1.25 times, and a retardation film 1 was obtained. The evaluation results are Shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com