Support Arm for a Work Machine

a technology for supporting arms and work machines, which is applied in mechanical machines/dredgers, soil shifting machines/dredgers, constructions, etc., can solve the problems of high cost, complex production and inspection of such welding seams, and relatively complicated cross-sections to manufacture, so as to achieve the lowest intrinsic mass and manufacturing with a minimum of effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

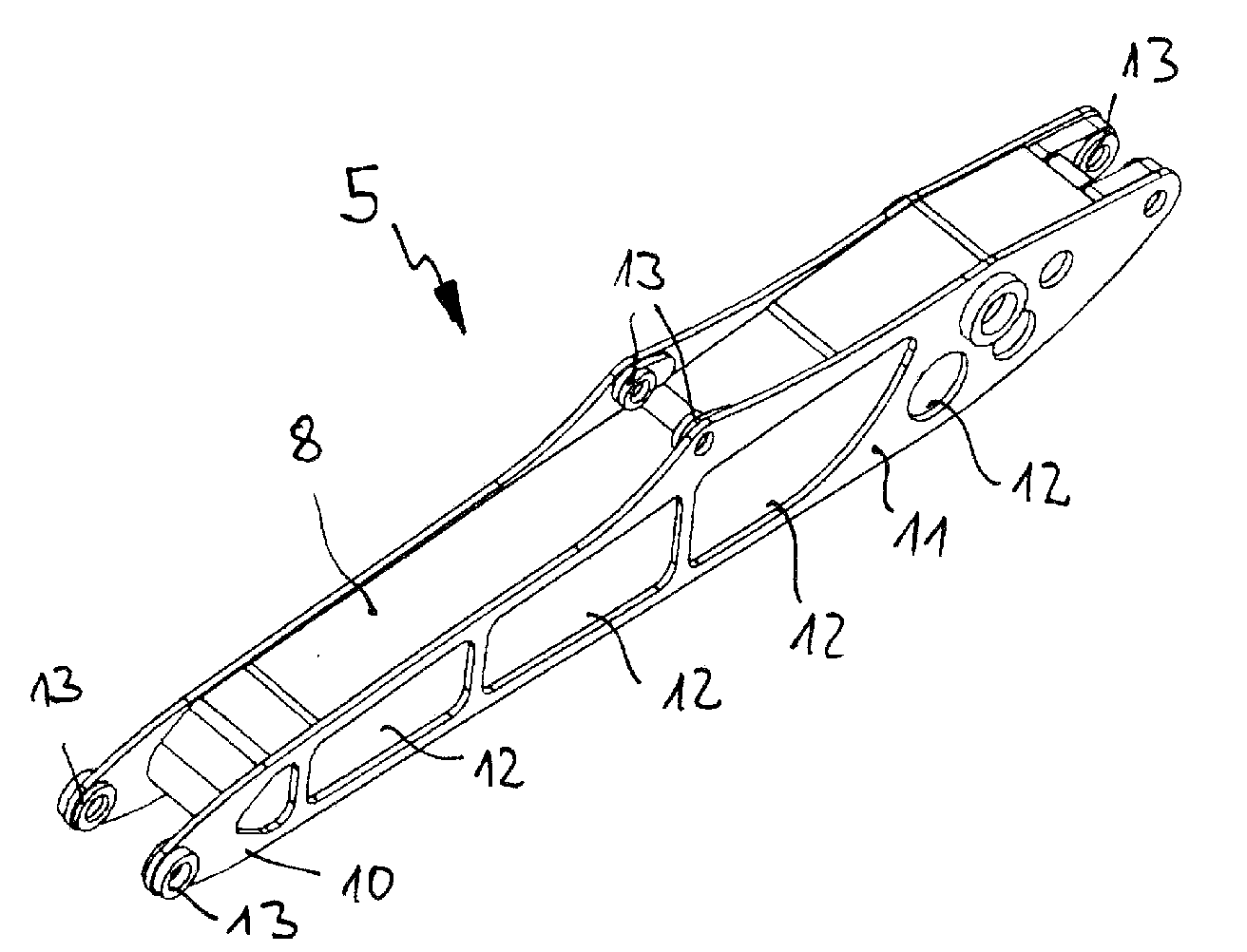

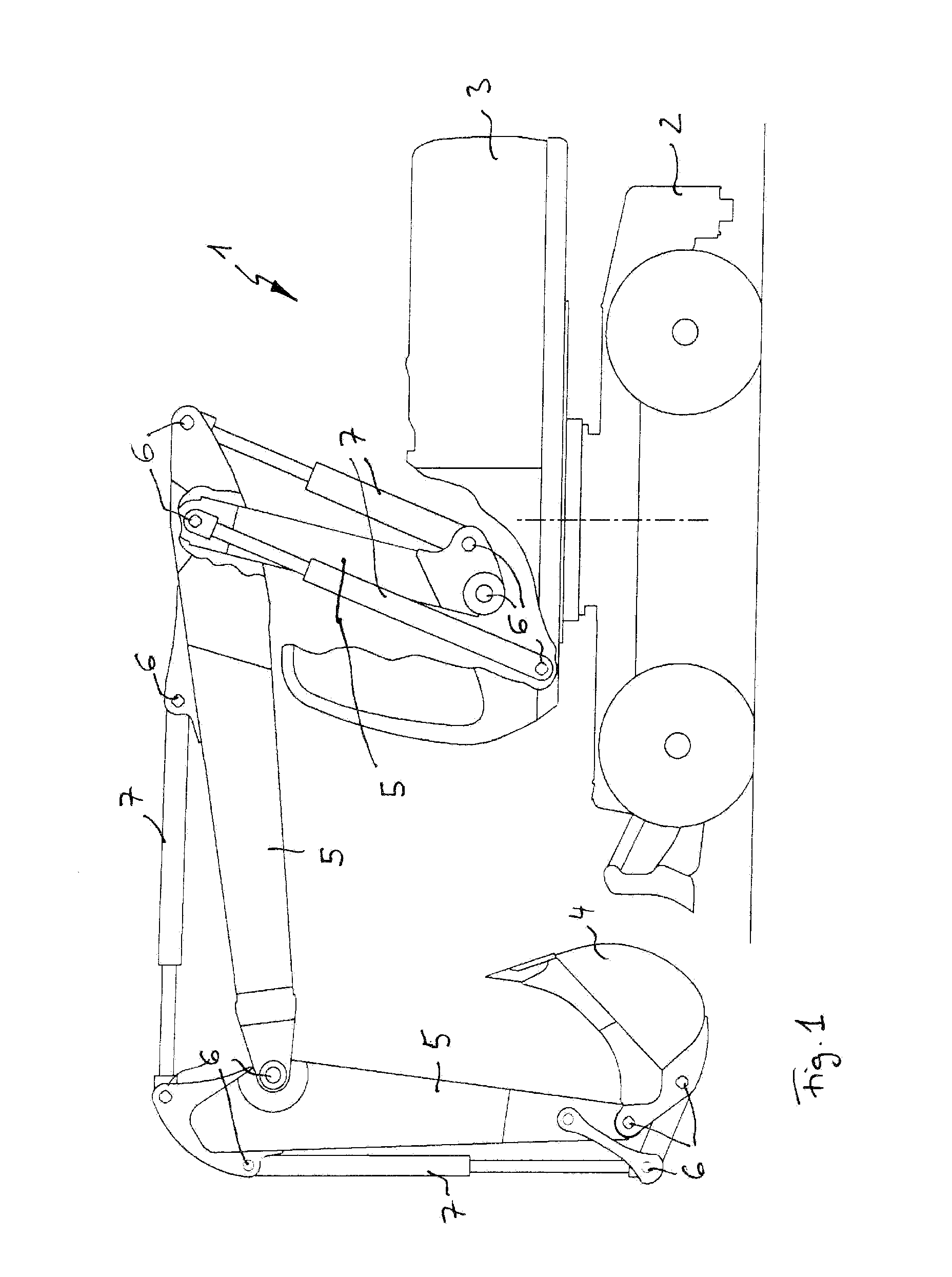

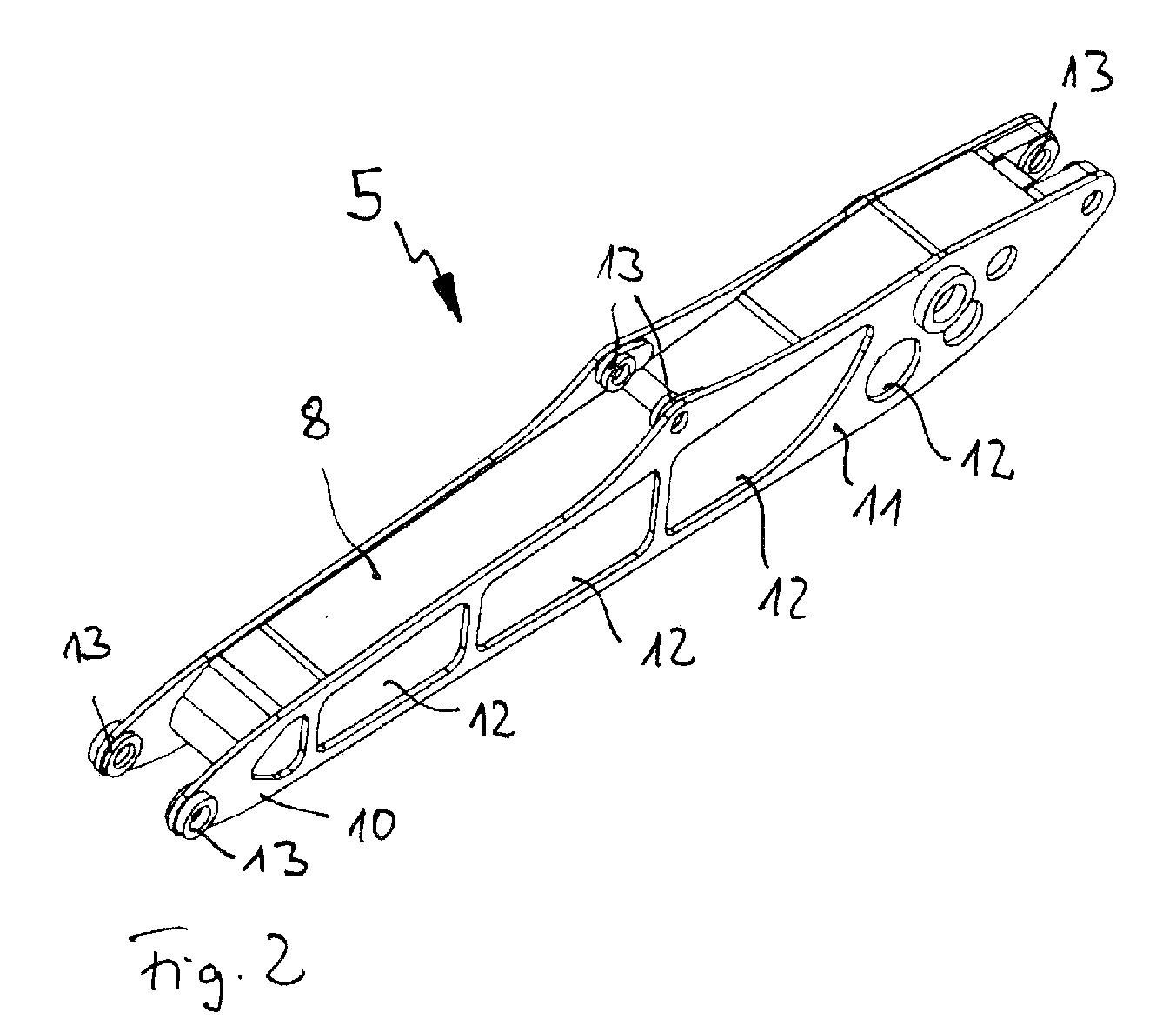

[0021]FIG. 1 shows an example of a work machine in the form of a machine generally referred to as an excavator and labeled here with 1. The following description of the design of a support arm according to the invention can be realized in general for any type of mobile or stationary work machine; excavator 1 shown in FIG. 1 is only an example of such a machine.

[0022]Excavator 1 has one lower carriage 2 and one upper carriage 3, and is equipped with a work tool in the form of a shovel 4. This shovel 4 is connected by work equipment consisting of several support arms 5 to excavator 1, and in particular to the upper carriage 3 of the same excavator. Other support arms, either individually or in combination, can also be connected to the lower carriage 2, of course, but this is not shown in detail in the drawing.

[0023]The individual support arms 5 of the work equipment of the excavator are connected by pin supports 6 to each other and to the hydraulic cylinders 7 moving the arms as well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com