Floor sanding sponge pads

a sponge pad and floor technology, applied in the field of floor sanding sponge pads, can solve the problems of difficult intercoat adhesion in the subsequent application of the coating, several problems for users, and the combination of two products is problematic, so as to prolong the life of the product, improve the appearance of the floor surface, and soften the scratch pattern. fine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

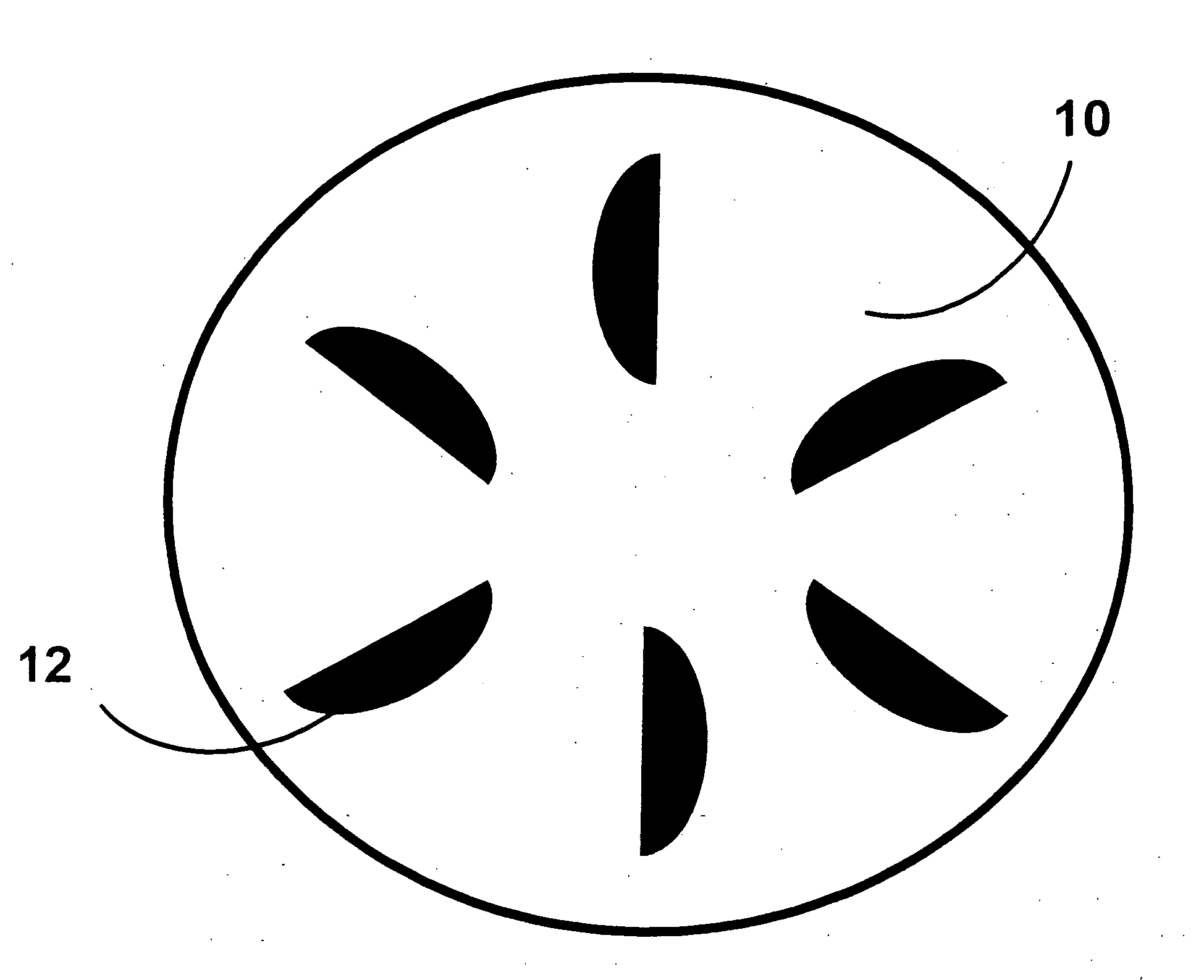

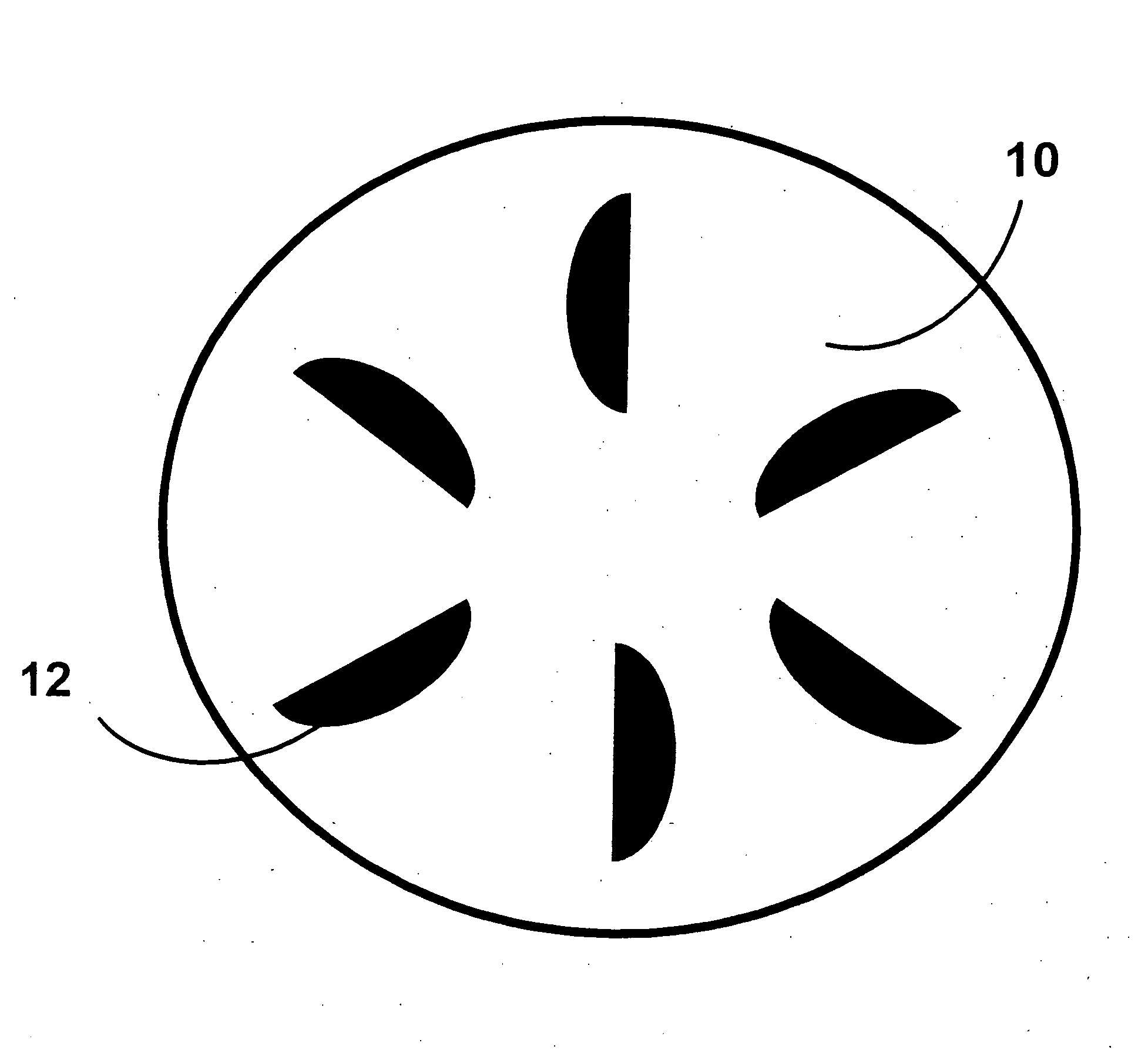

[0034]A ¼″ foam from Rempac Foam Corporation (Clifton, N.J.) is covered with aluminum oxide (A / O) abrasive grain. The grain is applied to the ¼″ foam by using gravity to coat a resin system that locks the grain in place. The material is then cut into a 16″ disc with six dye-cut vacuum holes. The vacuum holes allow the finish dust that is sanded off the floor to be collected by the vacuum system on the buffer.

example 2

[0035]Materials

[0036]Sol-Gel (SG) coated, A / O coated between coat pads. Grits tested were 100 grit for the SG, and 100, 120, 150 and 180 grit for the A / O. Testing was conducted using a standard 16″ diameter rotary floor buffer, equipped with dust collection. Products tested were compared against existing pad and coat system of Norton 16′ Maroon Conditioning Pad part #6626100020566 and Norton Aluminum Oxide Pressure Sheet Rolls (PSA) in 150, 180 and 220 grit.

[0037]Floor Sanding Method

[0038]The floor sanding sponge was used on a test floor of approximately 400 square feet. The floor was sanded, stained, and finished with two coats of Lenmar Rapid Seal Polyurethane, and two coats of BonaKemi Mega water-based urethane. The floor was divided into several sections to test each product by abrading after each coat of finish was applied. The products were then evaluated after each section was abraded, and after each coat of finish was applied.

[0039]Product Evaluation

[0040]The products were e...

example 3

[0043]Materials

[0044]SG coated in 60 and 100 grit, A / O coated between coat pads in 100 and 120 grit. Testing was conducted using a standard 16″ floor buffer.

[0045]Floor Sanding Method The floor sanding sponge was used on a test floor with an existing polyurethane finish that was approximately 15 years old. Four separate areas of 100, 150, 150, and 200 square feet were tested. The two 150 square feet areas were rated as in poor condition, with paint spills, deep scratches, and heavily worn areas throughout. The 100 and 200 square foot areas were in fair condition and contained areas of normal wear and scratching. The floors were sanded, stained, and finished with two coated of BonaKemi Mega Semi-Gloss urethane. The products were then evaluated after each section was abraded, and after each coat of finish was applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com