Method of stringing beads and article thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

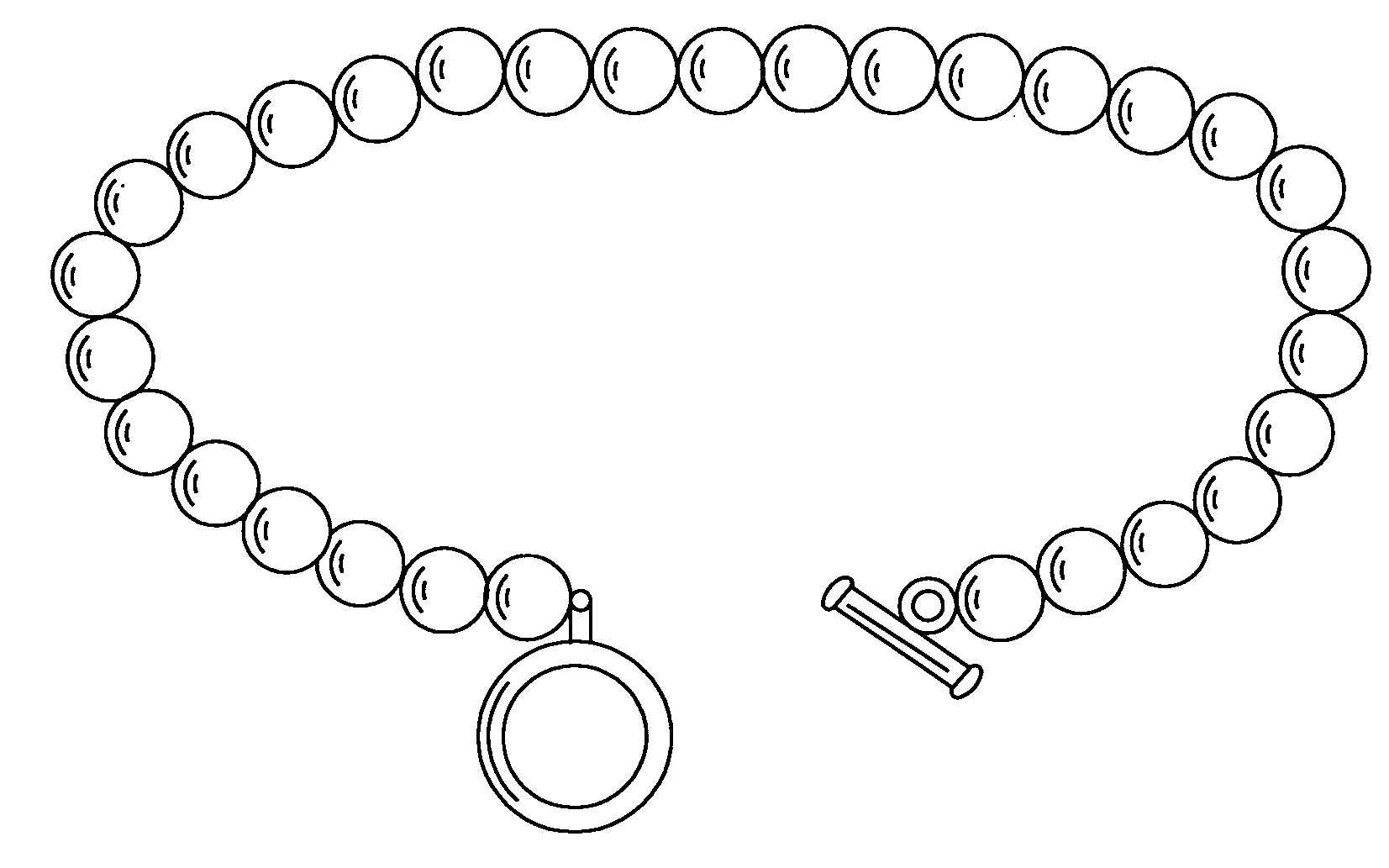

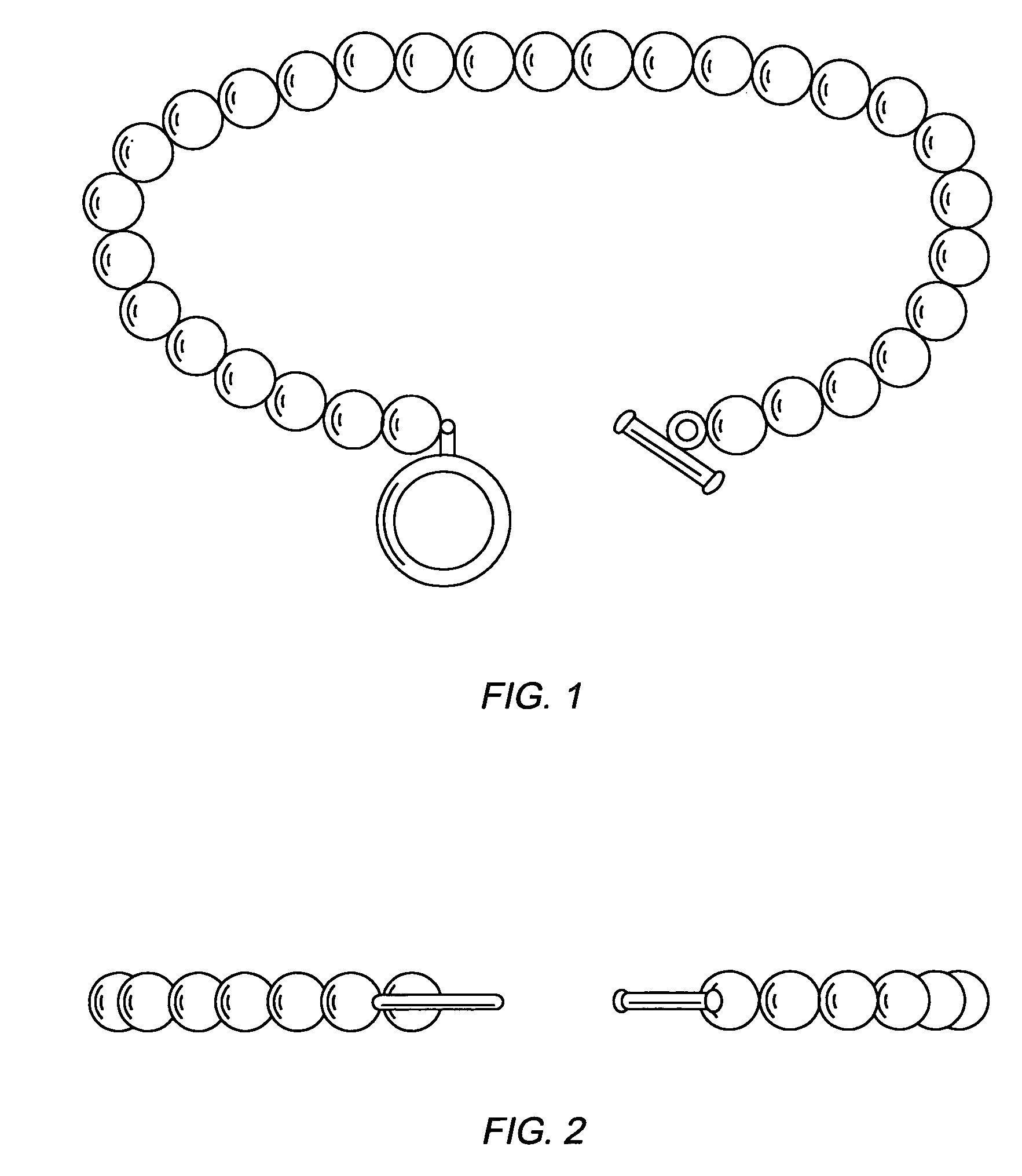

[0018]Referring now to the drawings wherein like numerals designate like and corresponding parts throughout the several views, in FIGS. 1 and 2 a crimpless necklace 20 is shown according to our invention. The distinguishing feature of our invention is that jewelry making does not require crimping or the use of special tools. Cost and time are reduced and appearance is improved.

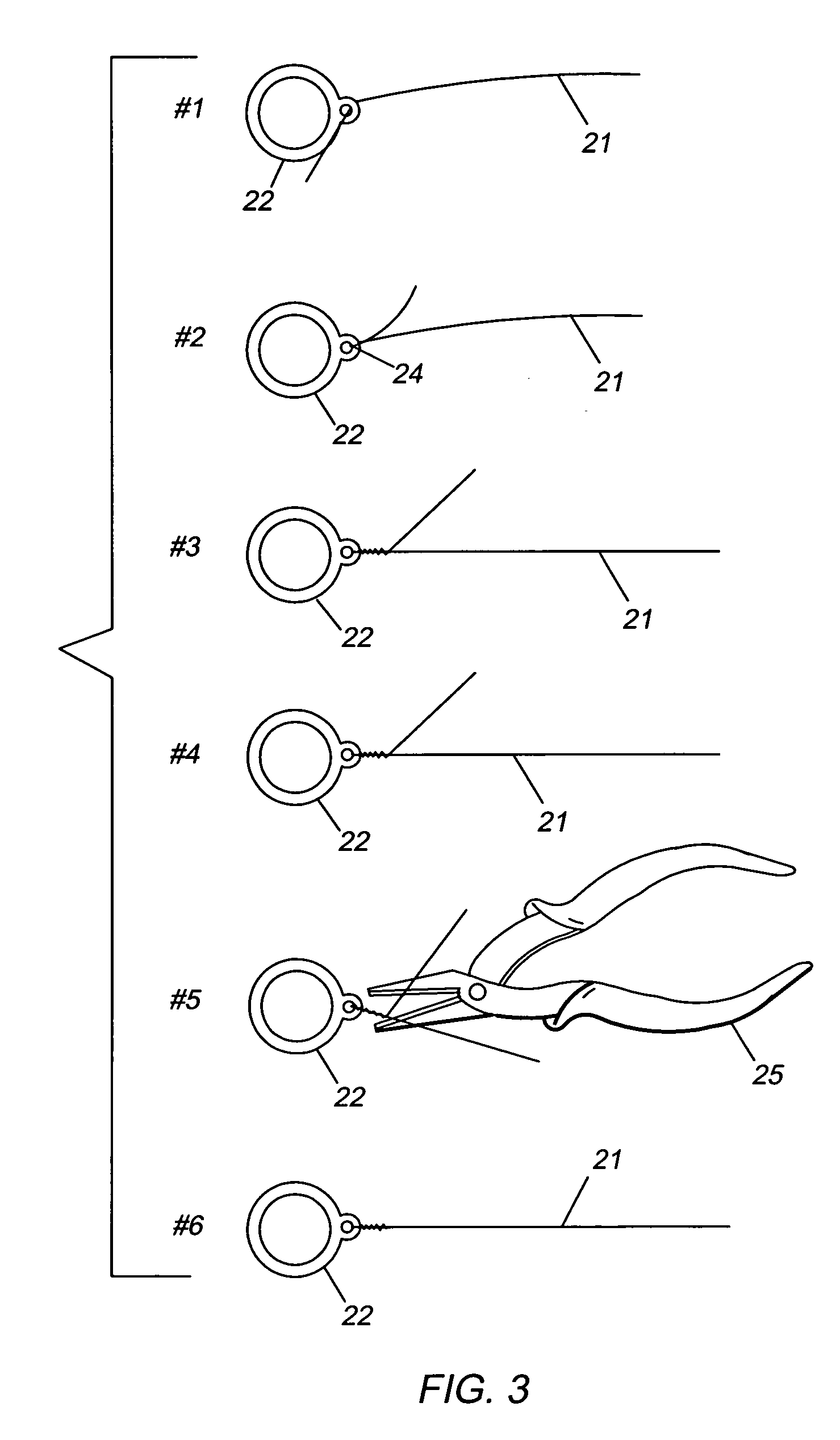

[0019]In the place of crimping beads and tubes, a wire 21 is tightly bent, twisted and knotted in a series of steps and procedures. A preferred wire 21 is a triple strand 0.015 inch diameter 1×3 nylon coated Type 403 austenitic stainless steel wire 21 with a heat number of 733497 or a wire with equivalent physical properties. The designated wire 21 is available at “5 Star Cable Company” of Rochester Hills, Mich. Deviations from the designated wire 21 that have been tested have failed to provide the desired results. The ductility and tensile strength of the designated wire 21 are high. The heat number, tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com