Heat dissipating device and heat conduction structure thereof

a heat dissipating device and heat conduction technology, which is applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of heat conduction structure dissipation, and achieve the best improve the heat dissipation efficiency of the heat dissipation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

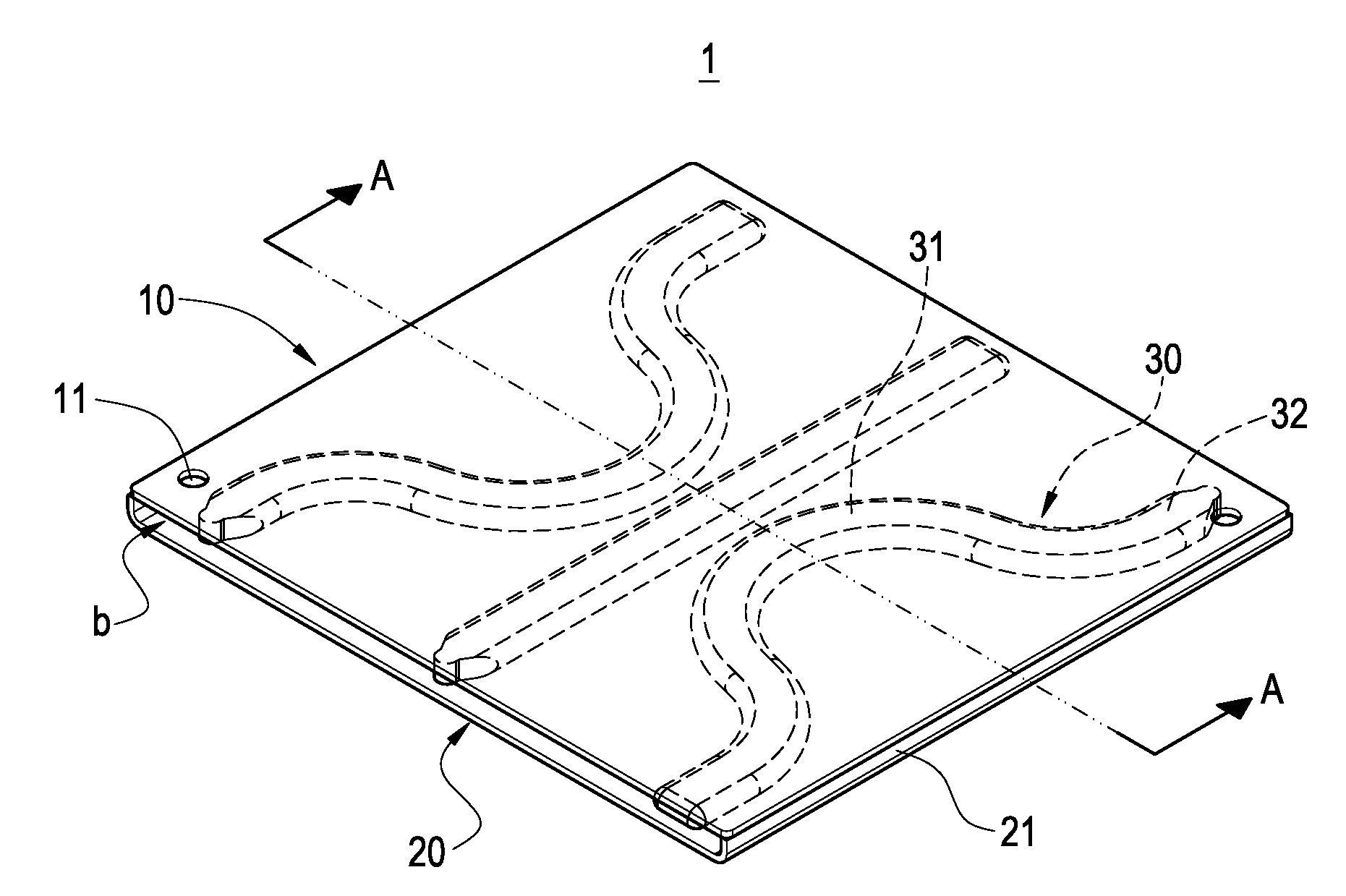

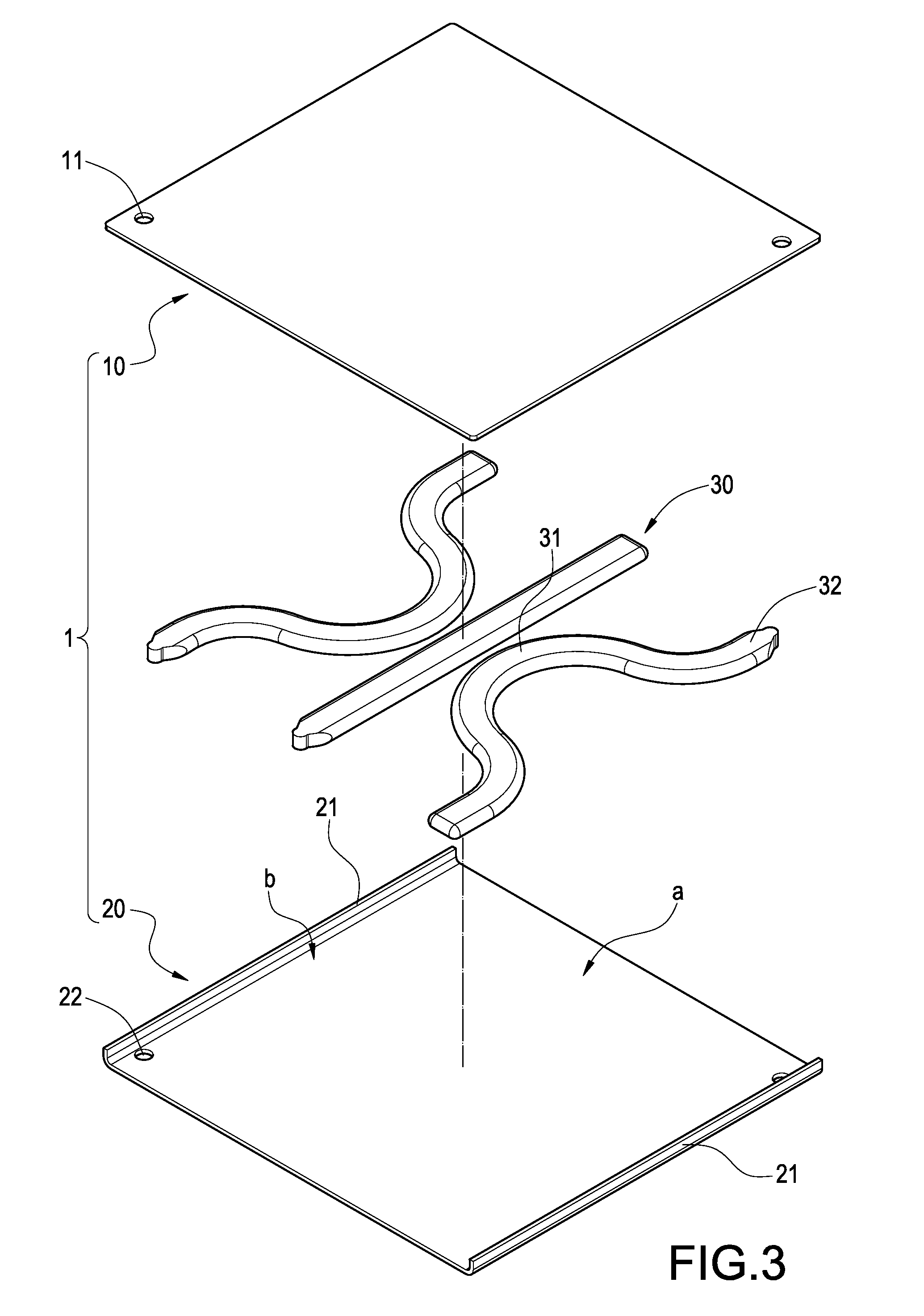

[0027]At least three heat pipes 30 are used in the present invention. The heat pipes 30 are arranged in the receiving space “a”, and sandwiched between the first heat conduction plate 10 and the second heat conduction plate 20. Each heat pipe 30 includes a heat absorbing section 31 and a heat emitting section 32 extending from each heat absorbing section 31. A plurality of heat dissipating passages “b” is formed between the heat emitting sections 32 and the walls 21. Each heat emitting section 32 is partially positioned in the heat dissipating passages “b”. Each heat pipe 30 has a tabular configuration.

[0028]Referring also to FIG. 6 to FIG. 7, an exploded view of a heat dissipating device of the present invention, and a lateral sectional view of the first embodiment of the present invention are shown. The heat dissipating device further includes a heat dissipating body 40 and a fan 50 (shown in FIG. 10). The heat dissipating body 40 is attached to the surface of the first heat condu...

third embodiment

[0032]Referring to FIG. 10, a top sectional view of the present invention is shown. This heat dissipating device includes a fan 50 disposed at a lateral side of the heat conduction structure 1 and connected thereto. The airflow generated from the fan 50 flows into the heat dissipating passage “b” to dissipate heat from the heat emitting sections 32 of the heat pipes 30. Therefore, the heat conducting efficiency of the heat conduction structure is improved. The whole heat dissipating device can be dissipated. The heat dissipating device can produce the best heat dissipating efficiency.

[0033]The heat dissipating device and the heat conduction structure of present invention has the following advantages: First, the heat pipes 30 are sandwiched between the first heat conduction plate 10 and the second heat conduction plate 20. The arrangement of the heat pipes 30 can be configured by the size of the heat generating element 61. Therefore, the heat dissipating device and the heat conductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com