Cylindrical magazine for discharging projectiles for toy guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

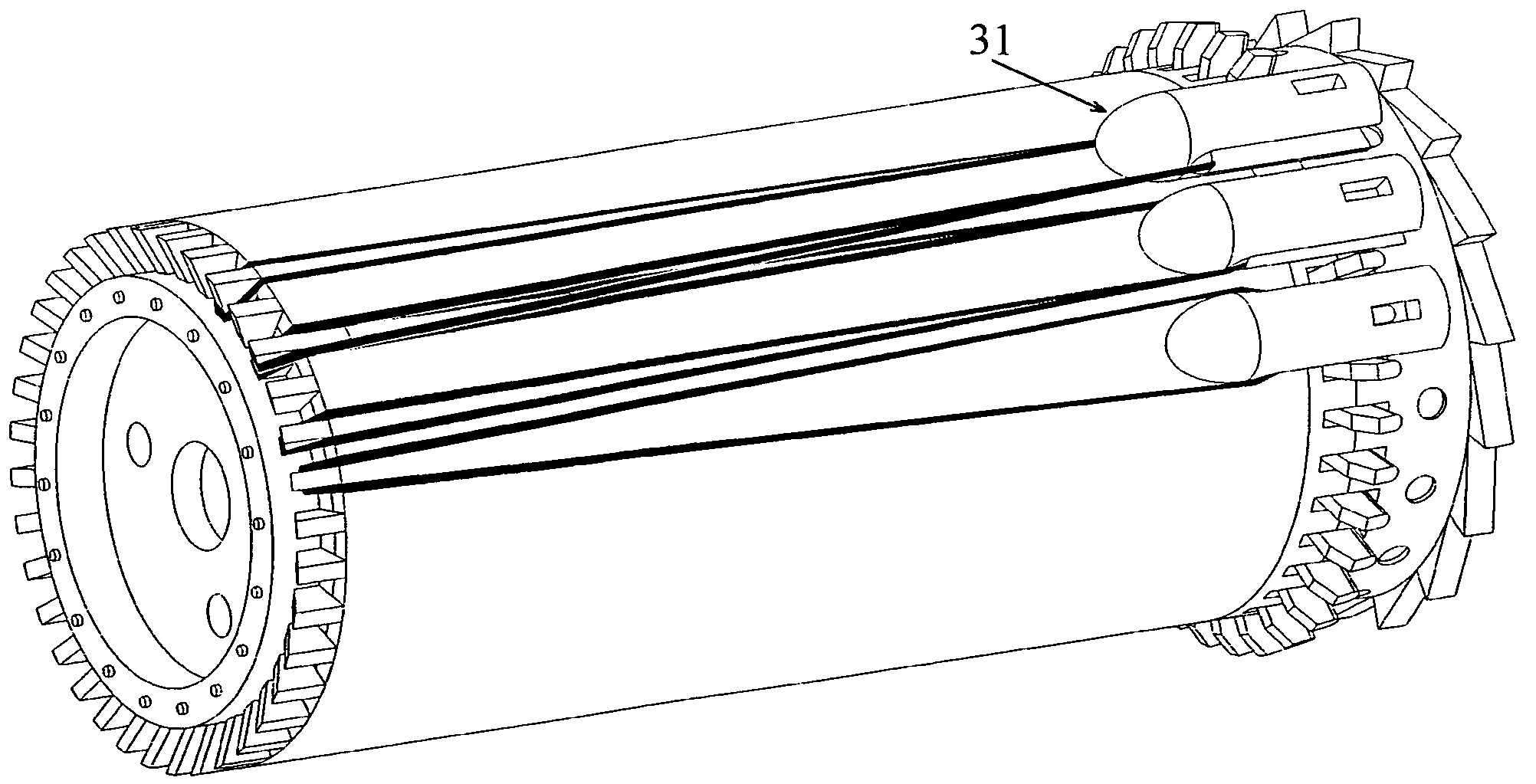

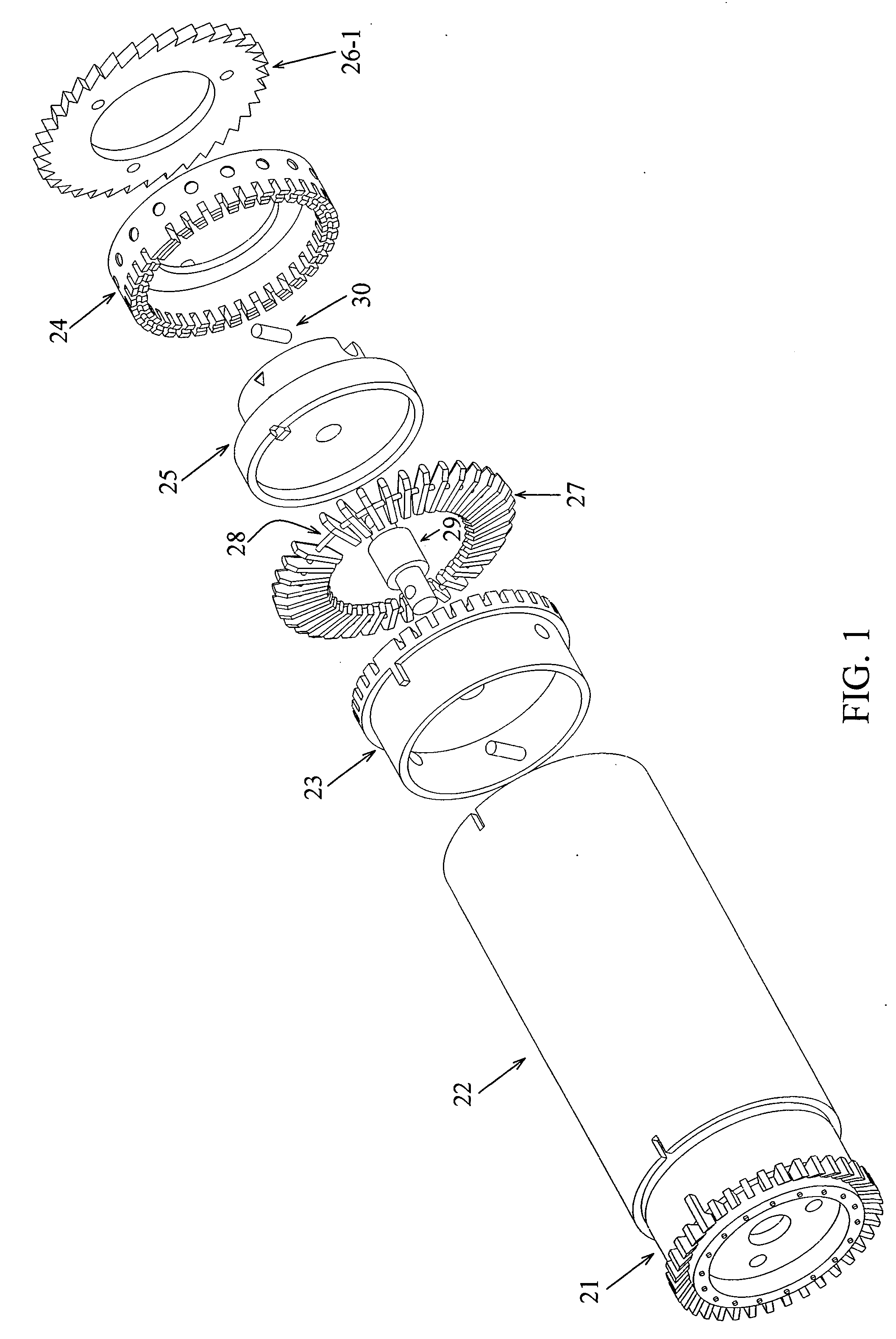

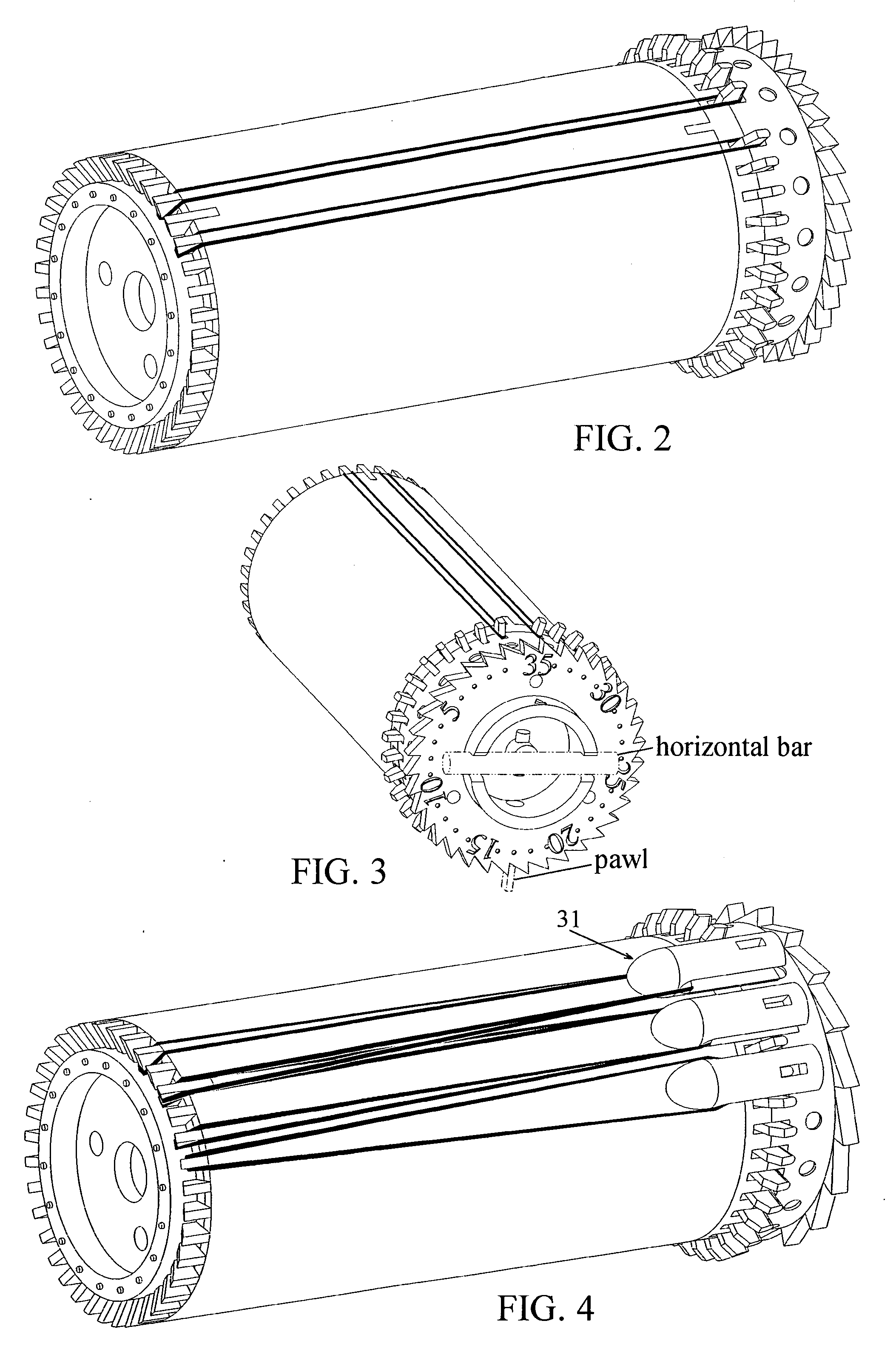

[0023]This magazine is designed to discharge stretched elastic bands in elastic band guns and projectiles propelled by stretched elastic bands in slingshot guns. For the ease of adapting to the above-mentioned purposes and to different types and numbers of elastic bands with a minimal number of components and redesigning, the magazine is assembled, referring to FIGS. 1-3 and more particularly to the drawings wherein like numerals of reference indicate corresponding parts throughout several views, from a hook block 21, a finger housing composed of a front portion 23 and a rear portion 24 to sandwich fingers 27 in the mortises formed by slots 23b (FIG. 8) and 24b (FIG. 9) strung by a circular wire ring 28 through a pivoting hole 27a (FIG. 13) in the finger and the wire ring between semicircular grooves 23d and 24d, a tube 22 of varying lengths for different types of elastic bands with slots 22a (FIG. 7) to match with a key 21a (FIG. 6) on the hook block and a key 23a on the front port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com