Glass forming apparatus and glass forming method

a technology of glass forming and glass forming, which is applied in the direction of glass rolling apparatus, glass making apparatus, manufacturing tools, etc., can solve the problems of not being economical, affecting the quality of glass forming, and the need to discard the forming die together with the heat exchange unit, so as to achieve favorable heat conduction, reduce cost, and enhance productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

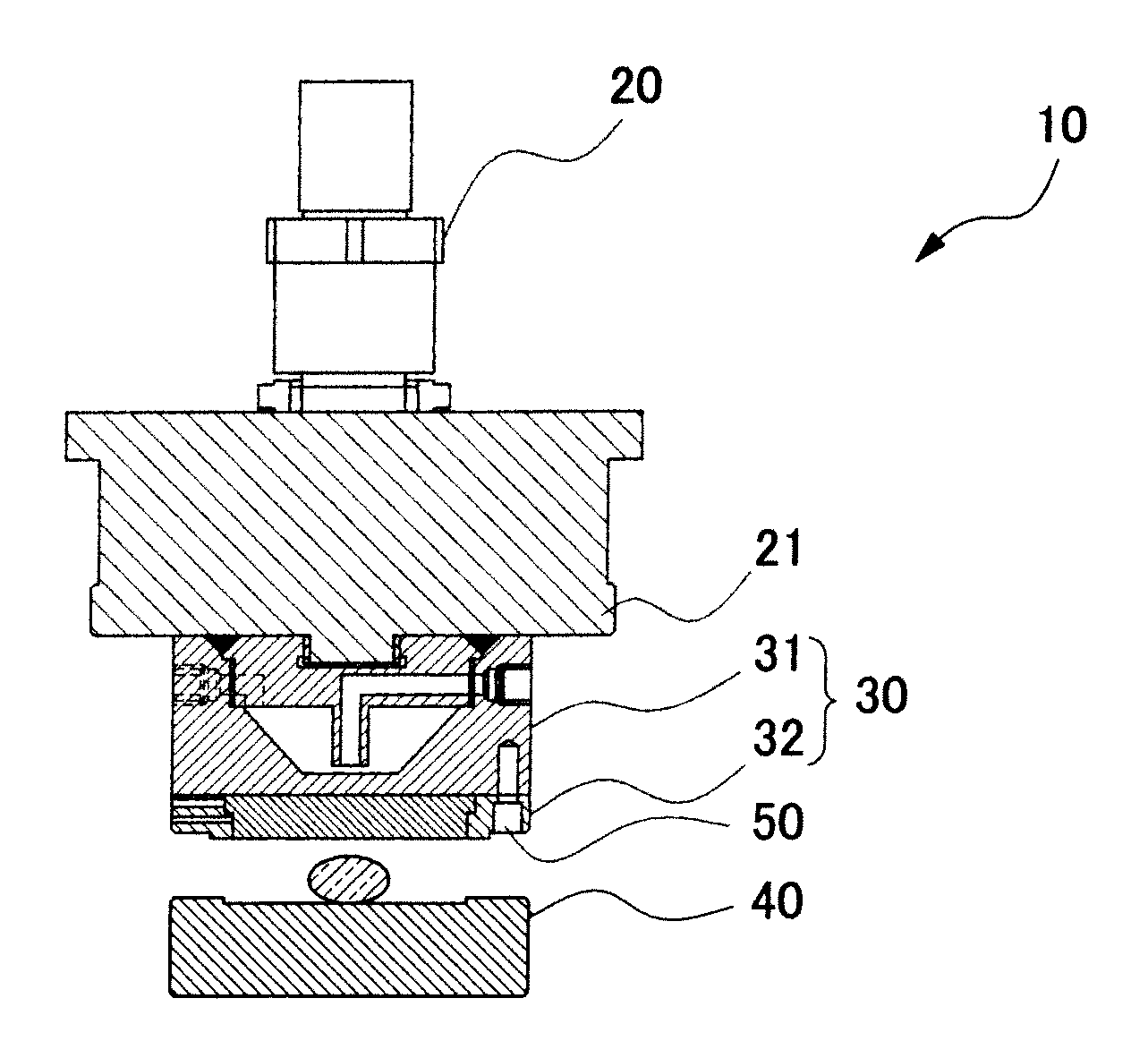

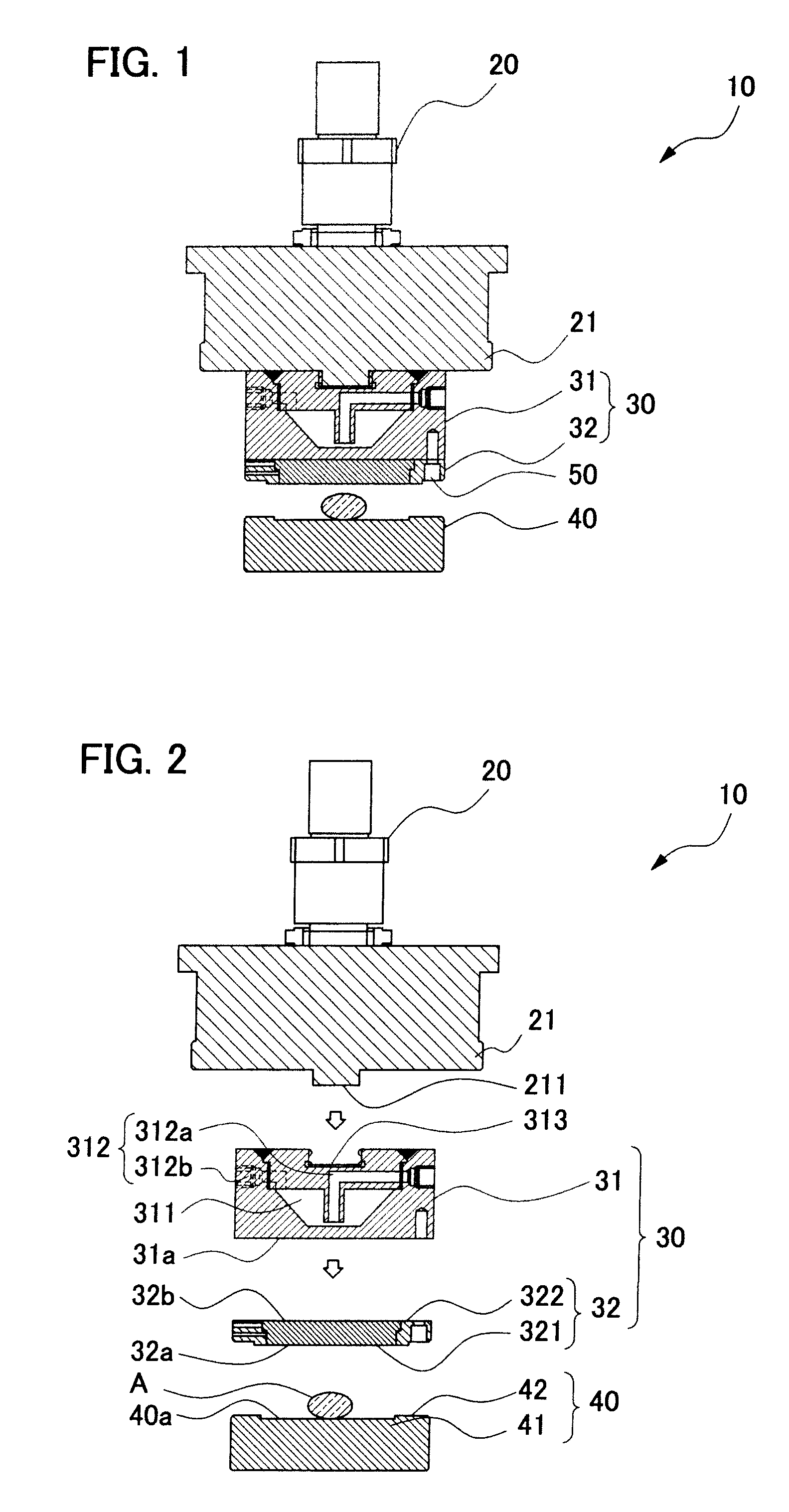

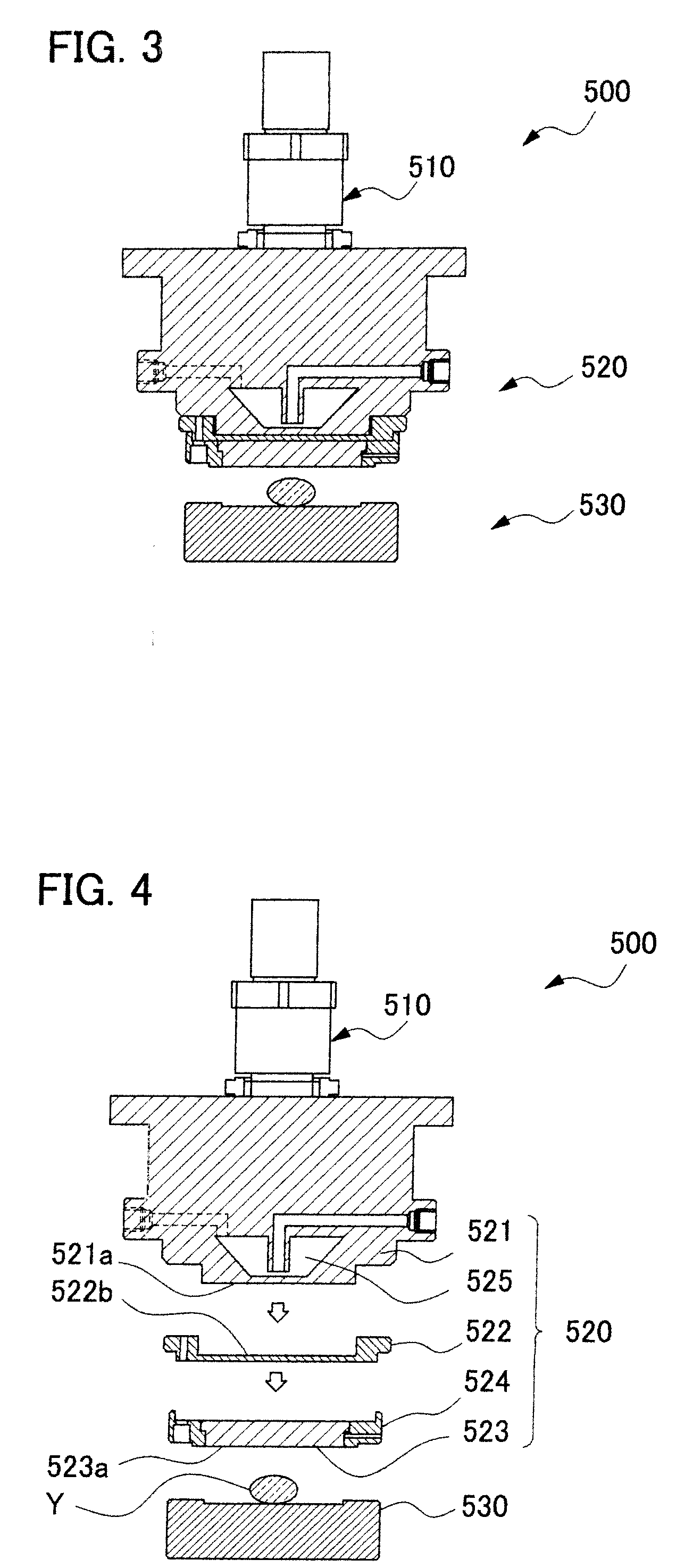

[0056]In the glass forming apparatus of the invention, the glass forming die is composed of a plurality of dies, and at least one of the dies is divided into a heat exchange unit and a press unit. In particular, since the press unit is in contact with the glass material and forms a glass product, is heavily worn, and is required to have a high surface precision, it must be replaced often; however, it is possible to replace only the press unit at this time, and the cost can be lowered. By quick replacement, productivity can be enhanced.

[0057]At least one part of dividing surfaces in contact with the heat exchange unit and the press unit has surface precision with flatness (PV) of 500 μm or less, more preferably 70 μm or less, or most preferably 10 μm or less, and surface roughness (Ra) of 100 μm or less, more preferably 20 μm or less, or most preferably 5 μm or less.

[0058]When the surface precision of at least one part of the dividing surfaces in contact with the heat exchange unit a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flatness | aaaaa | aaaaa |

| Ra | aaaaa | aaaaa |

| Ra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com