Wafer Container with Integrated Wafer Restraint Module

a technology of restraint module and wafer container, which is applied in the field of wafer containers, can solve the problems of slackening of the restraint module more easily, the size of the wafer container cannot be decreased, and the inability to easily clean tiny dust particles, so as to increase the accuracy of contact between the wafer and the container. , the effect of reducing the size of the wafer container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]In order to disclose the skills applied in, the objectives of, and the effects achieved by the present invention in a more complete and clearer manner, preferred embodiments are herein described below in detail with related drawings disclosed for reference.

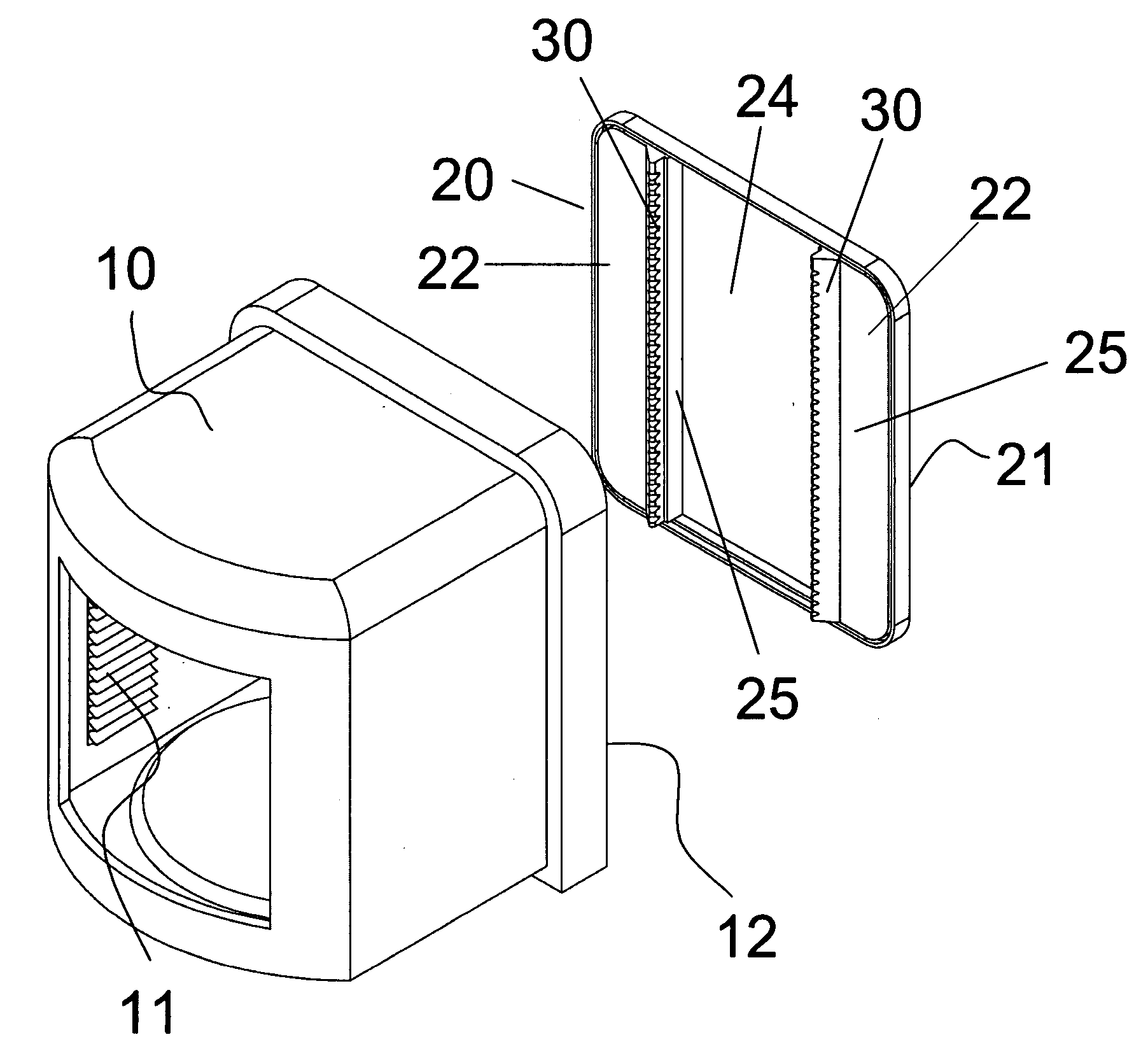

[0019]Referring to FIG. 3, which is a view of front opening unified pod (FOUP) of the present invention. The front opening unified pod (FOUP) includes a container body 10 and a door 20. A plurality of slots 11 are disposed in the container body 10 for supporting a plurality of wafers, and an opening 12 is formed on one sidewall of the container body 10 for importing and exporting the plurality of wafers. The door 20 includes an outer surface 21 and an inner surface 22. Around the central area of inner surface 22 of door 20 is disposed with a recess 24; therefore the recess 24 can separate the inner surface 22 of door 20 into two platforms 25. Since no other component is disposed in the recess 24, the recess 24 can be used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com