Thin substrate pitch measurement equipment

a thin substrate and measurement equipment technology, applied in measurement devices, material analysis, instruments, etc., can solve the problems of inability to quantitatively measure the distance between wafers, and the inability to detect sag or concavity of wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]In order to disclose the skills applied in, the objectives of, and the effects achieved by the present invention in a more complete and clearer manner, preferred embodiments are herein described below in detail with related drawings disclosed for reference.

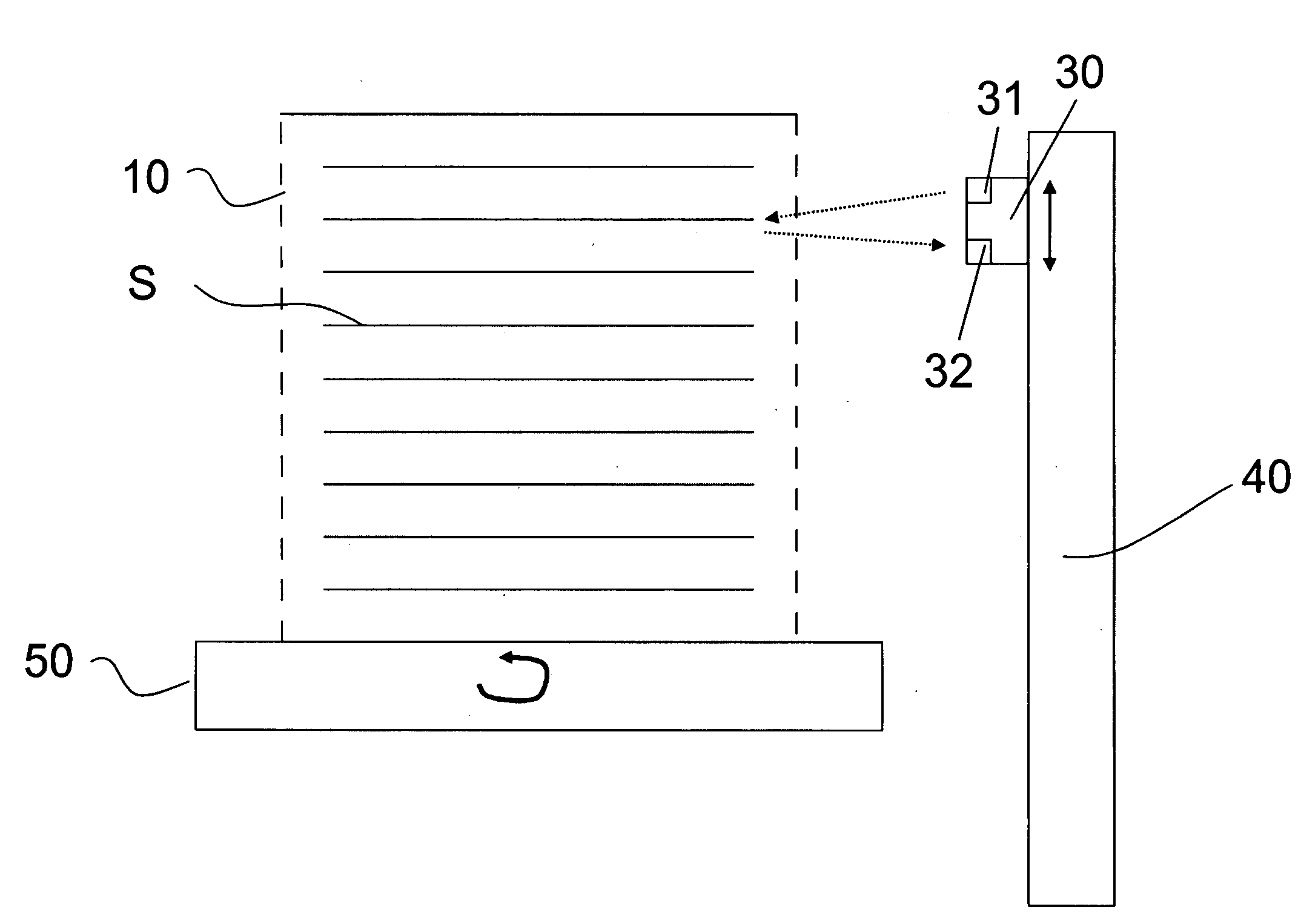

[0022]Referring to FIG. 3, which is a view of a thin substrate pitch measurement equipment of the present invention. The thin substrate pitch measurement equipment includes an optical component 30, a scanning device 40, and a rotation base 50, wherein the optical component 30 is disposed on the scanning device 40 and includes at least a light-transmitter 31 and a light-receiver 32, and the rotation base 50 carries a container body 10 having a plurality of thin substrates S within its interior. The light-transmitter 31 of the aforementioned optical component 30 can be used to transmit a light beam to one of the thin substrates S within the interior of the container body and the light-receiver 32 can be used to detect the ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plurality of angles | aaaaa | aaaaa |

| heights | aaaaa | aaaaa |

| displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com