Cyclically operating machine for filling containers

a container and cycle technology, applied in the direction of liquid handling, applications, caps, etc., can solve the problems of time-consuming, difficult, and complicated construction of continuous operating machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

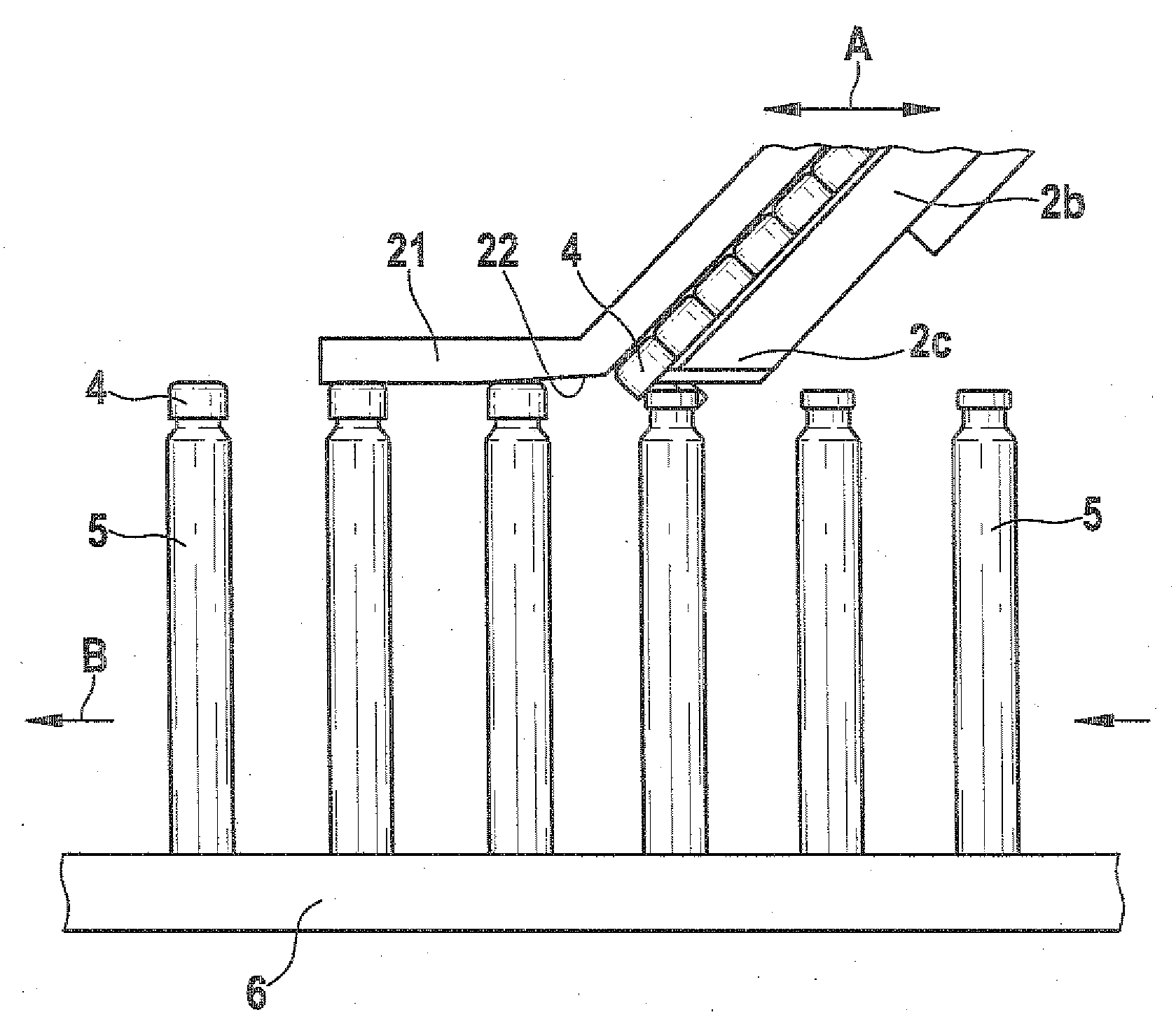

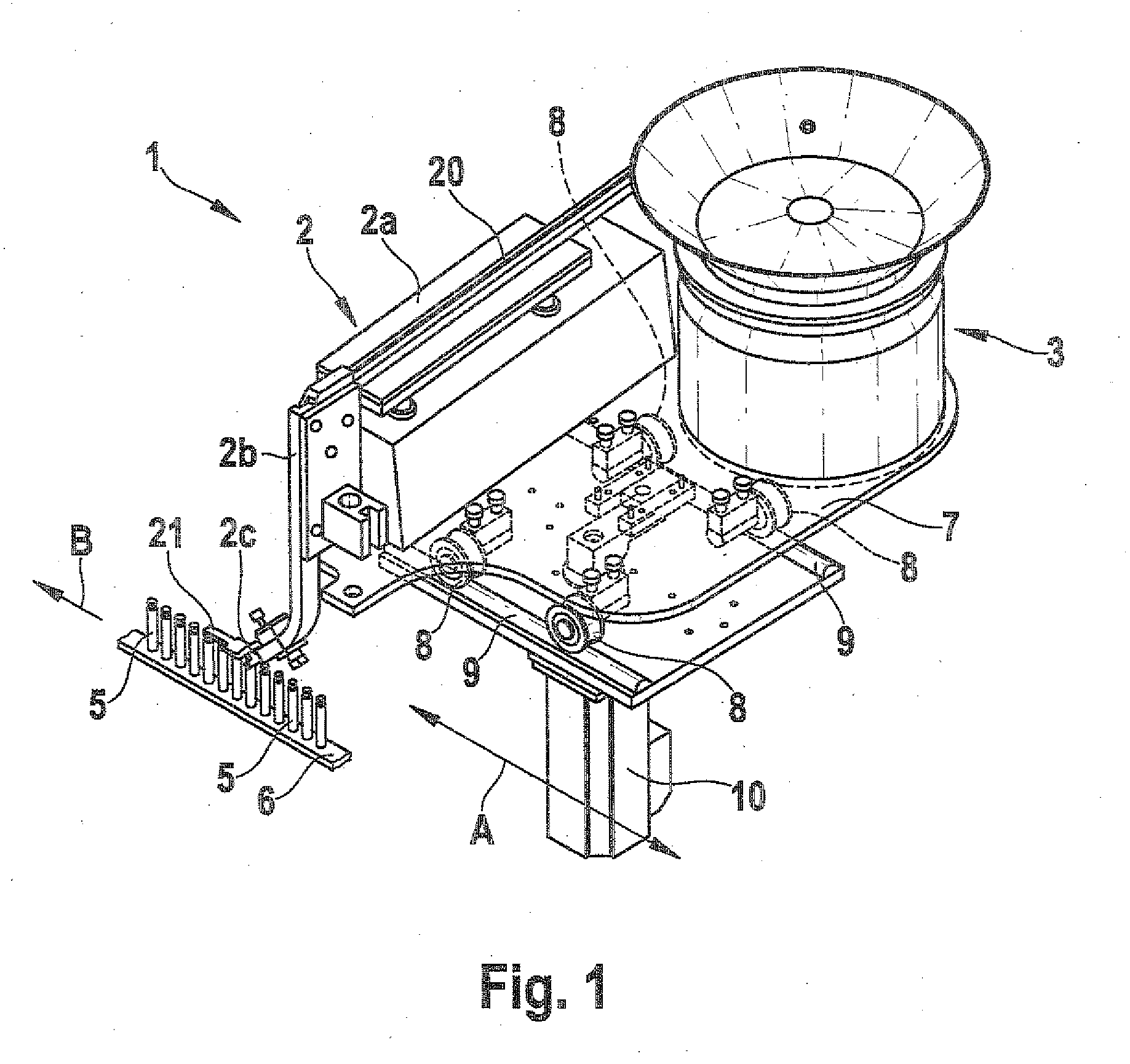

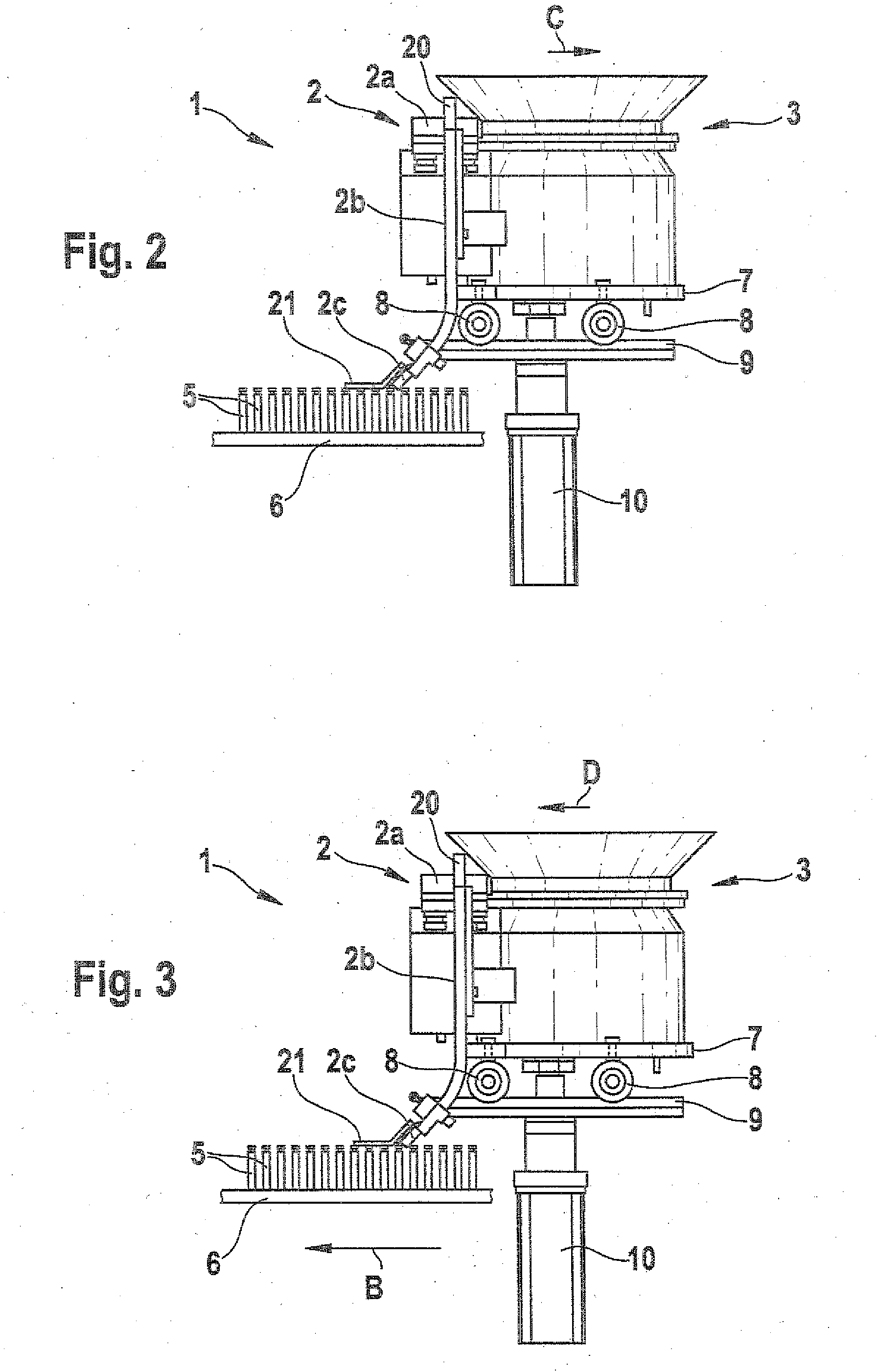

[0022]Below, in conjunction with FIGS. 1 through 4, a cyclical machine for filling and closing containers 5 in a first exemplary embodiment will be described in detail; in FIGS. 1 through 4, only a closure station 1 of the cyclical machine is shown, to which already-filled containers 5 are delivered. The cyclical filling of the containers, for instance with medications or the like, is effected in a known manner.

[0023]As shown in FIG. 1, the closure station 1 of the cyclical machine includes a cap feeder 2 and a sorting device 3. The sorting device 3 has the task of orienting and separating the caps and delivering them to the cap feeder 2. The cap feeder 2 includes an essentially horizontal rail region 2a with a delivery rail 20 and an essentially vertical rail region 2b. In the cap feeder 2, the caps 4 are delivered individually and in succession in the correct position to one end 2c of the vertical rail region 2b. At the end 2c of the vertical rail region 2b, there is a cap shoe 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com