Methods for less invasive glenoid replacement

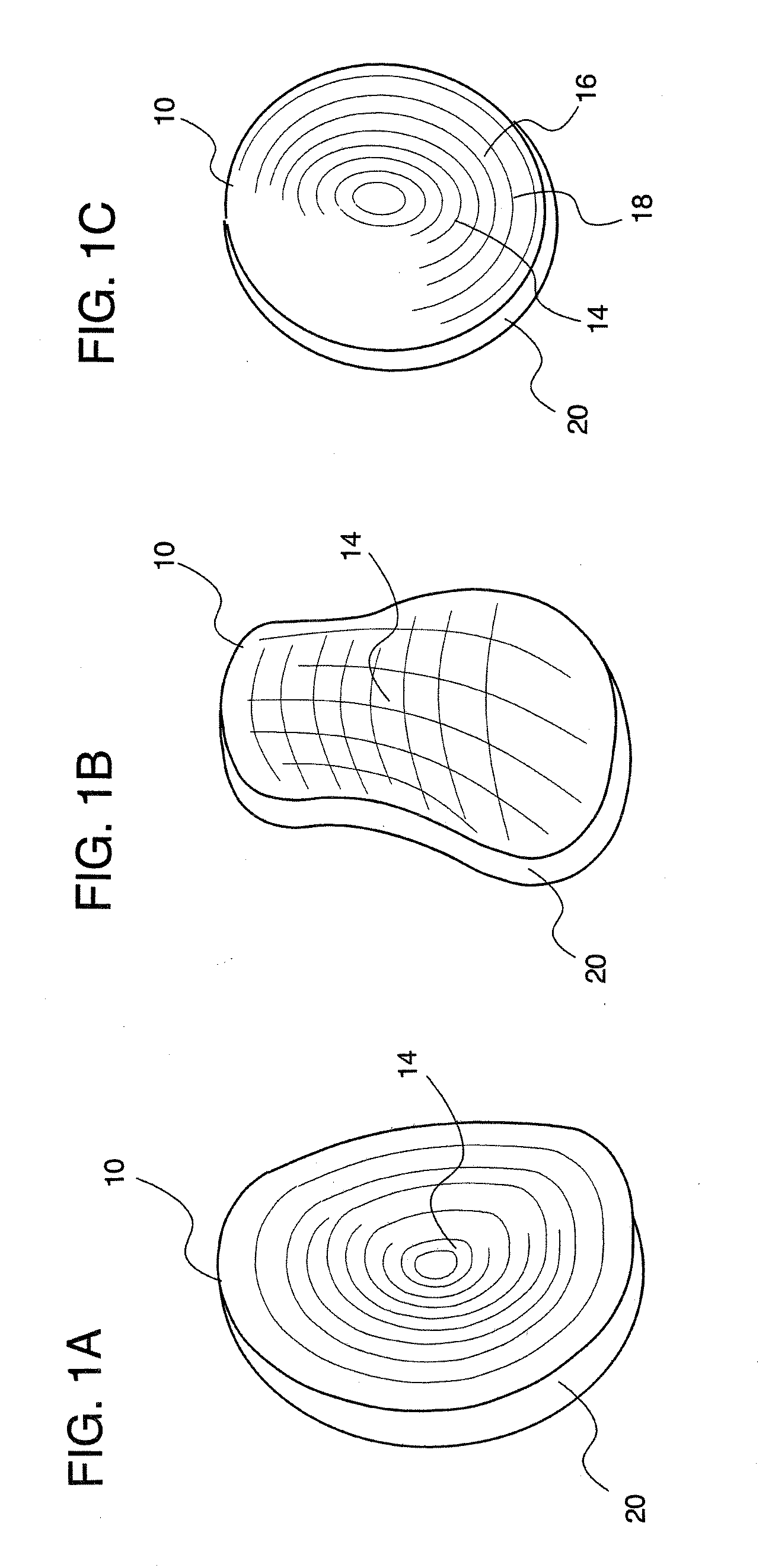

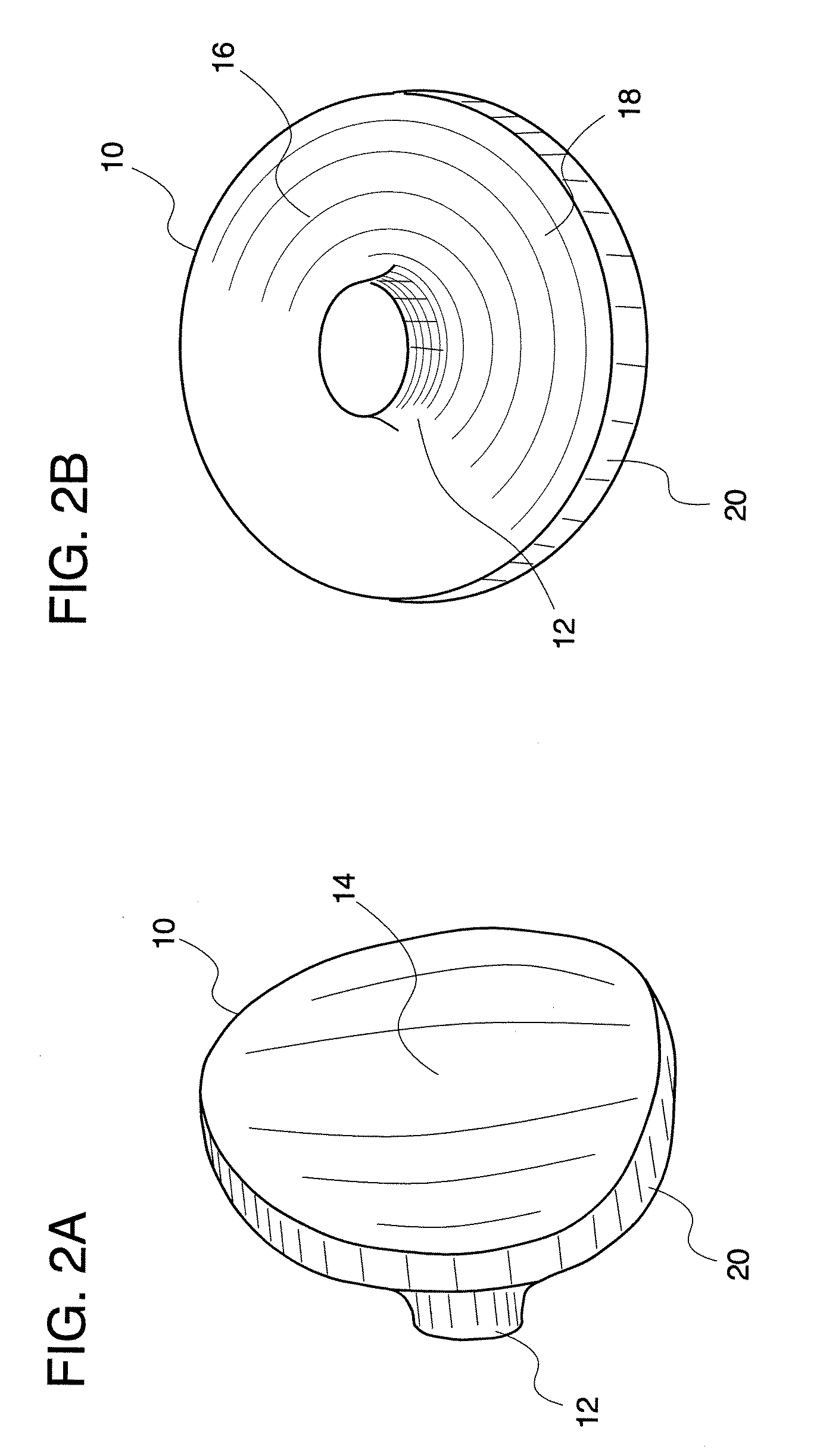

a glenoid surface and less invasive technology, applied in the field of glenoid surface replacement, can solve the problems of limiting the life of glenoid implants, and reducing the number of indications for which they can be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0095]A 62 year old woman presented with progressive, debilitating shoulder pain from osteoarthritis, which she had experienced for approximately 15 years. She had constant pain (rated 9 / 10) and difficulty washing her hair, fastening her bra, lifting a cup of coffee, and performing other daily activities. The preoperative radiographs and CT scan showed severe shoulder arthritis and glenoid bone loss that would preclude the use of a keeled or pegged glenoid implant. There was concern that a hemiarthroplasty procedure (replacement of the humeral ball, which would leave the arthritic glenoid socket bare) would not relieve the patient's pain.

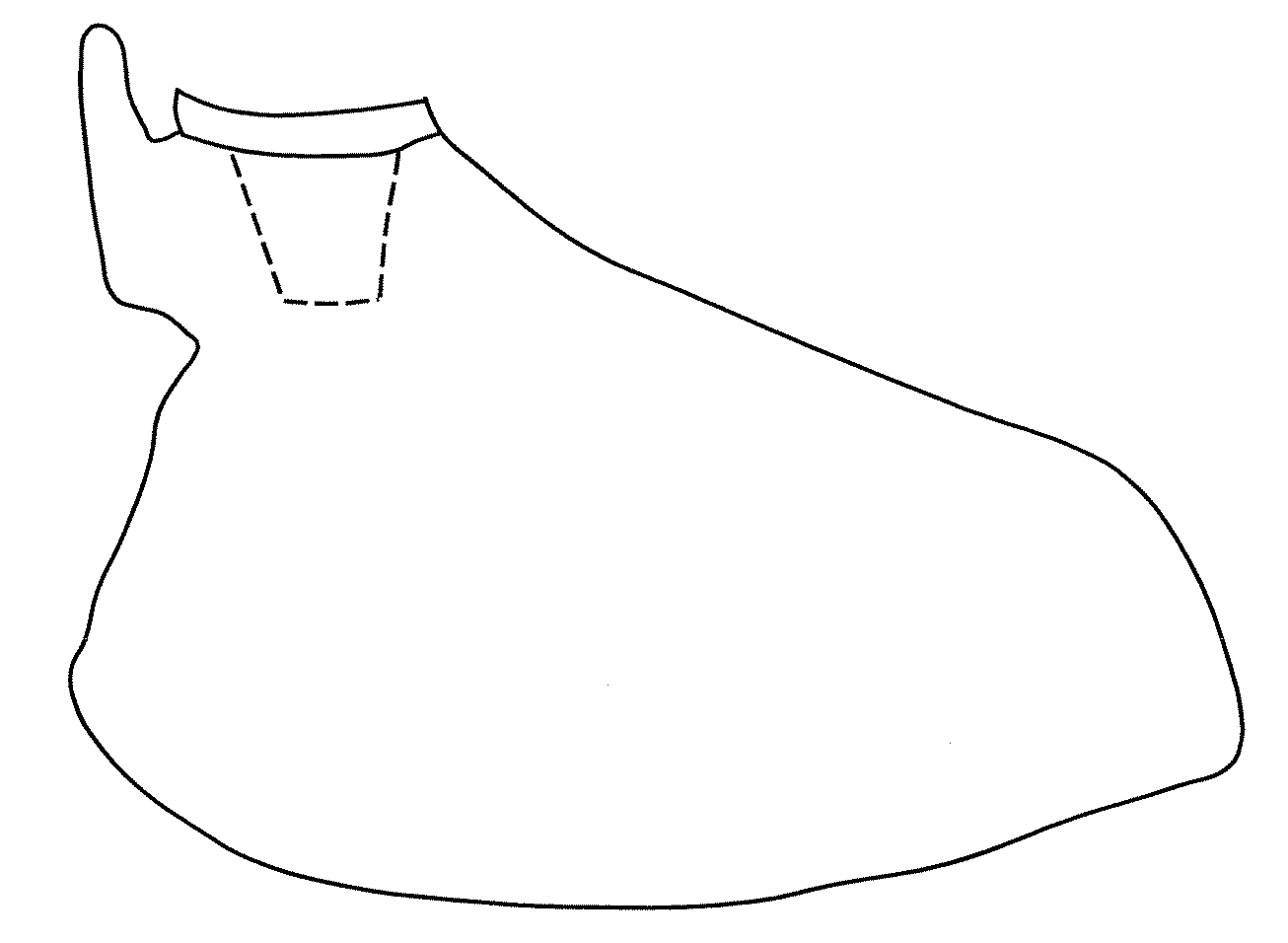

[0096]A total shoulder replacement using an inset glenoid implant of the invention and a standard humeral implant was performed. The smaller size and circumferential fixation of the inset glenoid implant allowed safe placement of the prosthesis within the confines of the patient's deficient glenoid cavity.

[0097]The deficient glenoid vault was not fr...

example 2

[0099]An 81 year old woman presented with severe shoulder pain and stiffness. She had severe shoulder arthritis with medial wear causing glenoid bone loss. Her own assessment of shoulder function was 25% of normal (American Shoulder and Elbow Society validated outcome score [ASES score] was 25).

[0100]A total shoulder replacement using an inset glenoid implant prosthesis was performed. Two months after her surgery, the patient had no pain and exhibited improved function. Her own assessment of shoulder function was 70% of normal (American Shoulder and Elbow Society validated outcome score [ASES score] was 70).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com