Stacked thin-film superlattice thermoelectric devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

MODE(S) OF IMPLEMENTATION

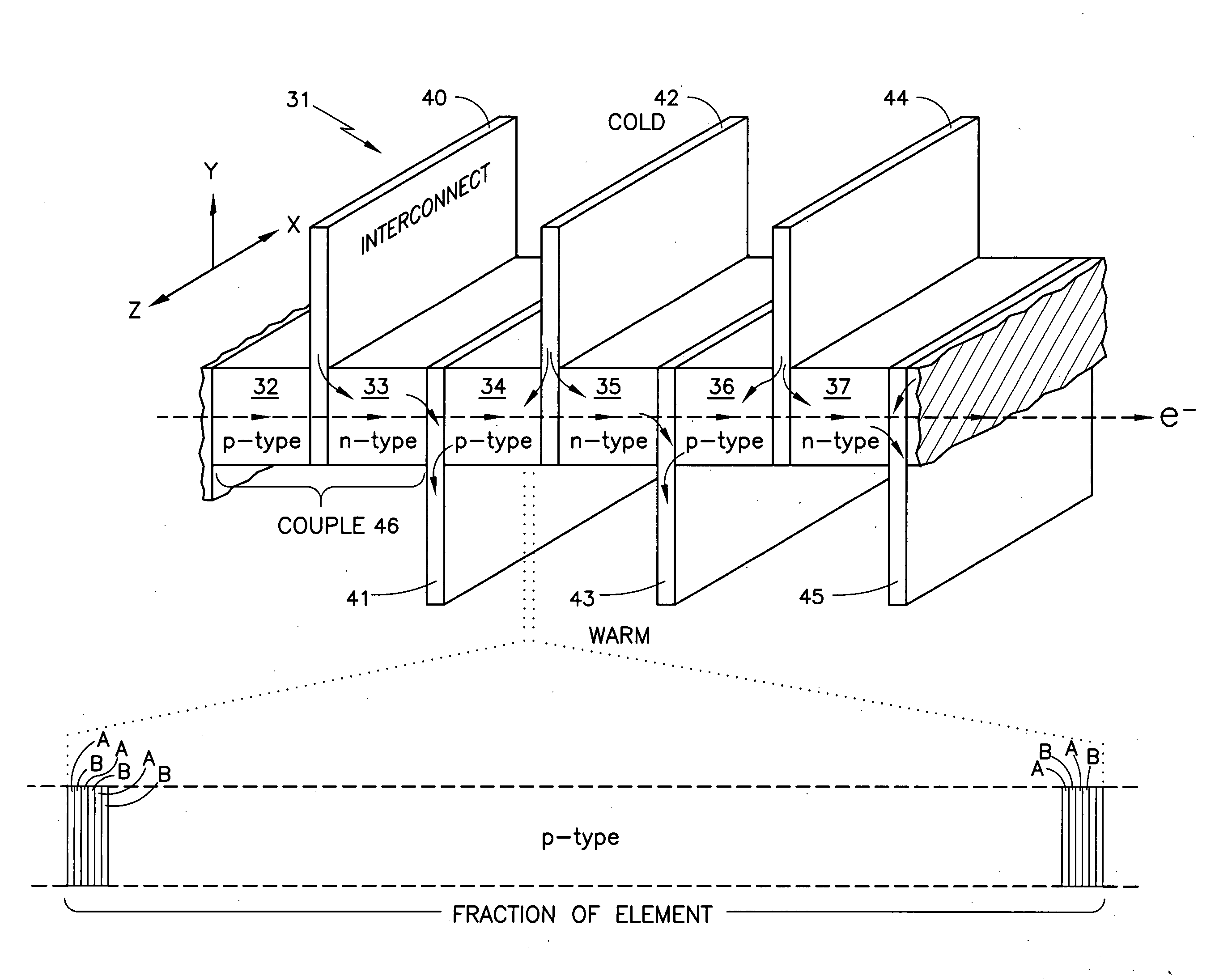

[0023]Referring to FIG. 1, a conventional thermoelectric device 7 includes a plurality of elements 10-13 each comprising a single thermoelectric alloy. The elements 10-13 are traditionally formed of Group V-VI semiconductor elements from the Bi2Te3—Sb2Te3—Bi2Se3 ternary system of materials. The alloy of the p-type elements 10, 12 may comprise, for instance, a ternary alloy of antimony, bismuth and tellurium, such as Sb1.5 Bi0.5 Te3.0. The alloy of the n-type elements 11, 13 may comprise a ternary alloy of bismuth, tellurium and selenium, such as Bi2 Te2.7 Se3.0. The bulk-material elements 10-13 may typically be approximately cubic in shape (not to be confused with cubic crystal structure), with between about 0.1 mm and 1.0 mm in each of the X, Y and Z directions.

[0024]The elements 10-13 are serially connected through interconnects (INT) 16-20. The upper interconnects 17, 19 are thermally and electrically insulated from the lower interconnects 16, 18 and 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com