Temperature adjustable airflow device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

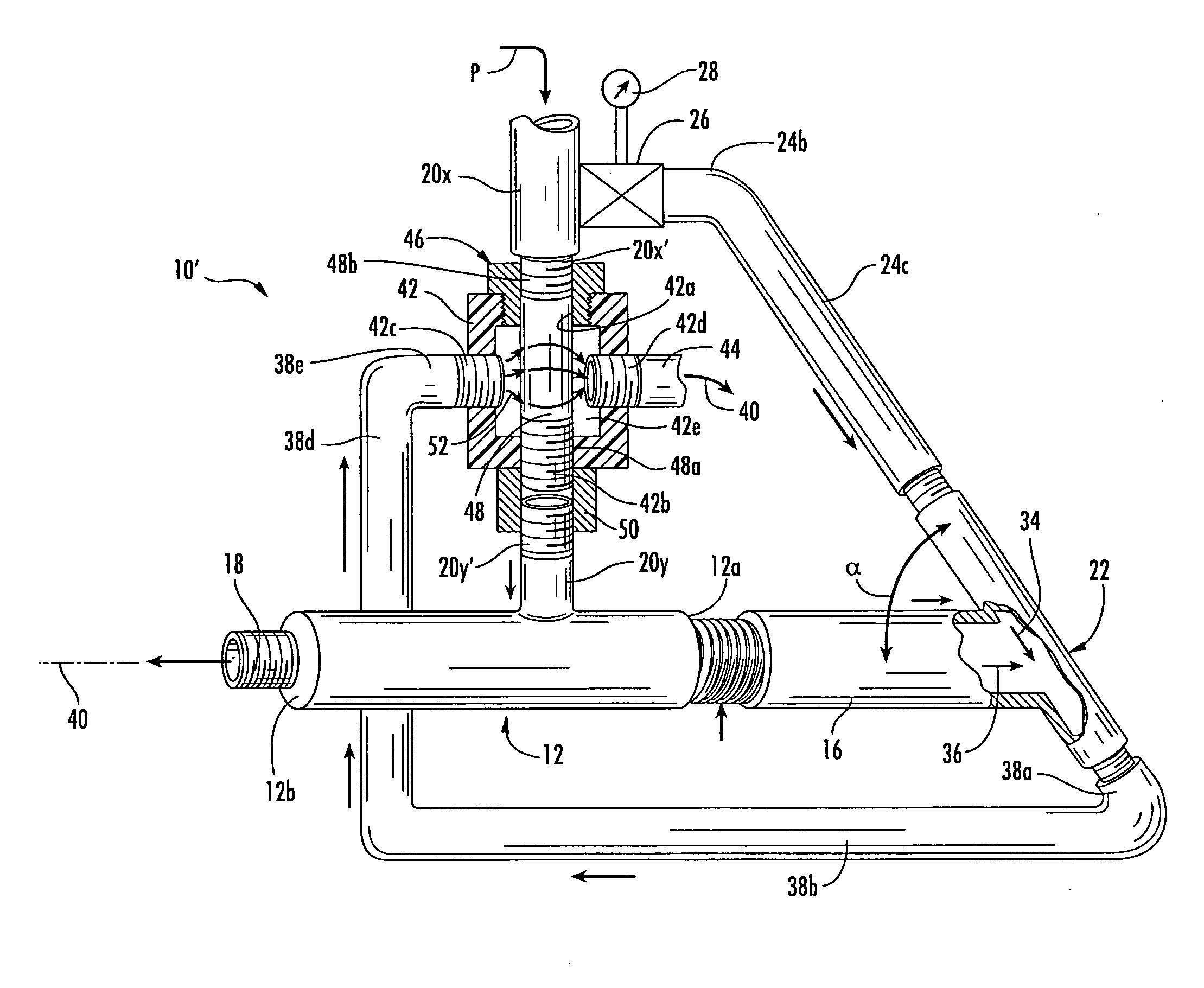

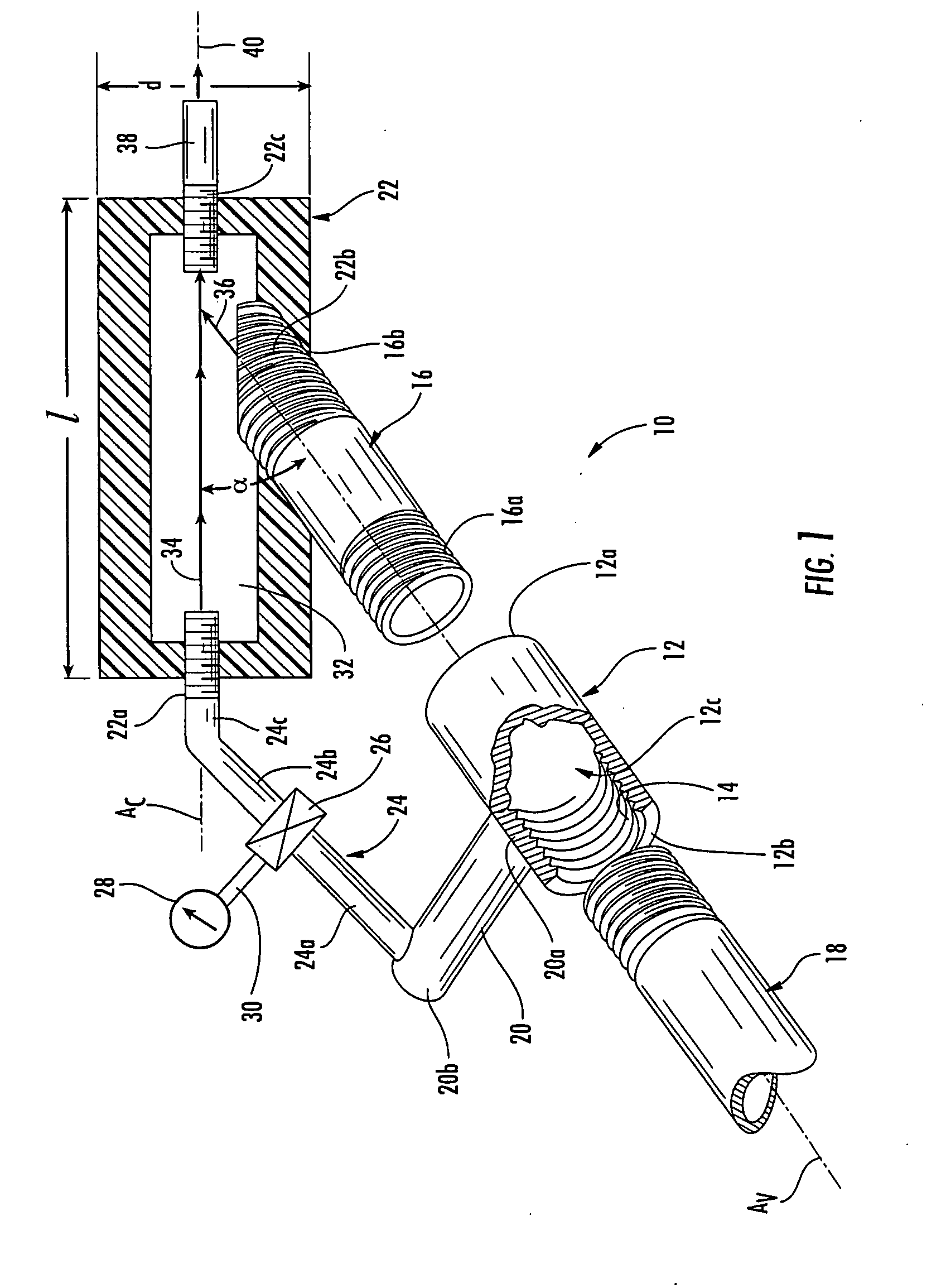

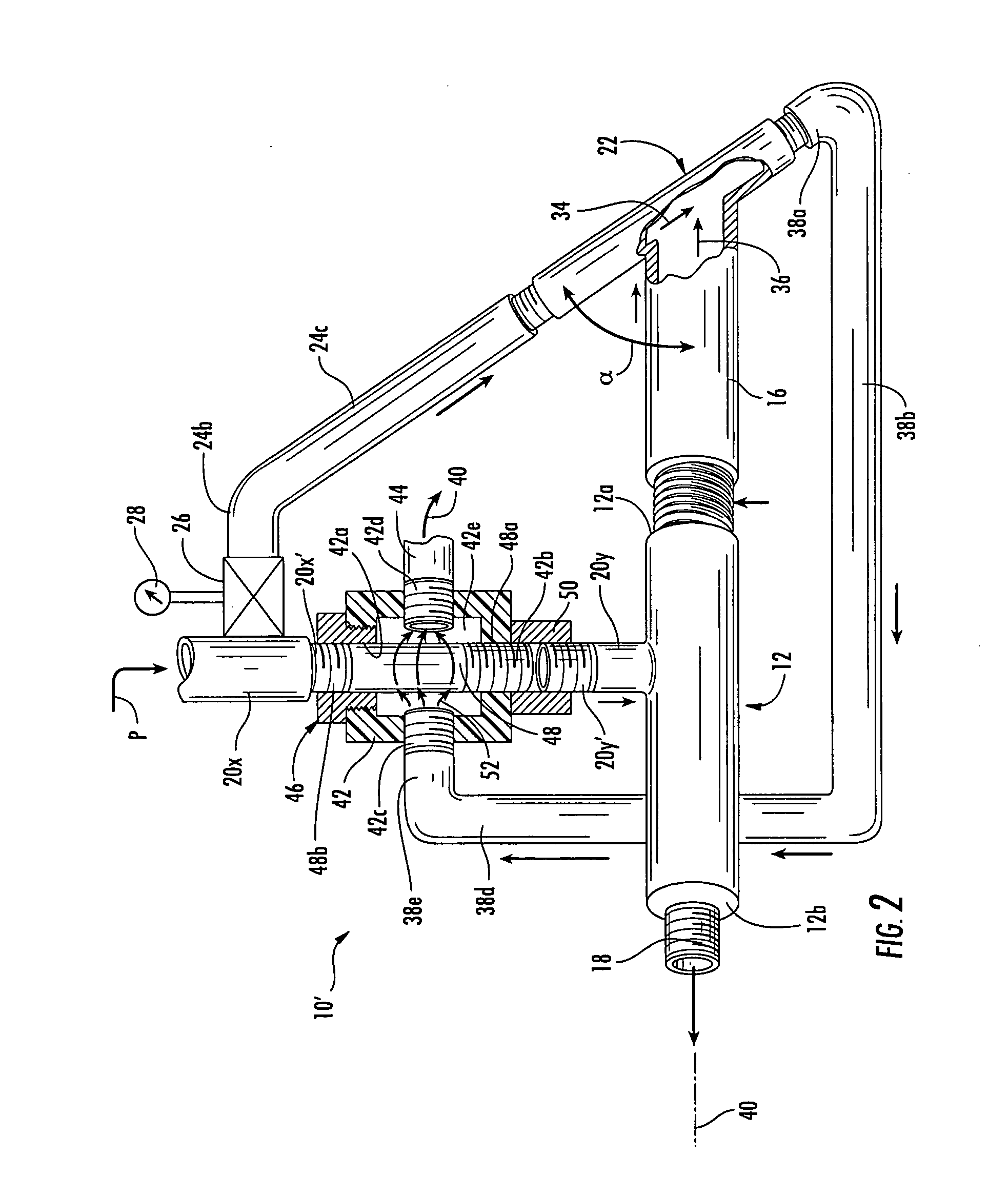

[0027]Referring specifically to the single Figure, a temperature adjustable airflow device in accordance with the invention is generally designated by the reference numeral 10.

[0028]The device 10 includes a vortex tube 12 having a cold end outlet 12a, a hot end outlet 12b, and a spiral chamber 12c. The internal construction of the vortex tube is conventional and the details need not to be described. All of the patents that mentioned in the background of the invention are incorporated herein for the teachings of the details of the vortex tubes, and any such construction can be used. The specific construction or details of the vortex tube are not critical and the subject invention may be used with any conventional or modified vortex tube of the type well known to those skilled in the art.

[0029]The vortex tube 12 has at each of the ends 12a and 12b internal threads 14. A cold air pipe 16 is provided with an external tread 16a at one end and an external tread 16b at the other end, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com