Assembly and method for vehicle suspension

a vehicle and suspension technology, applied in the field of truck assembly, can solve the problems of undesirable use of all lower power motors in a first model in place of all higher power motors in a second model, increase of parts inventory, etc., and achieve the effect of linear effective spring rate and non-linear effective spring ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

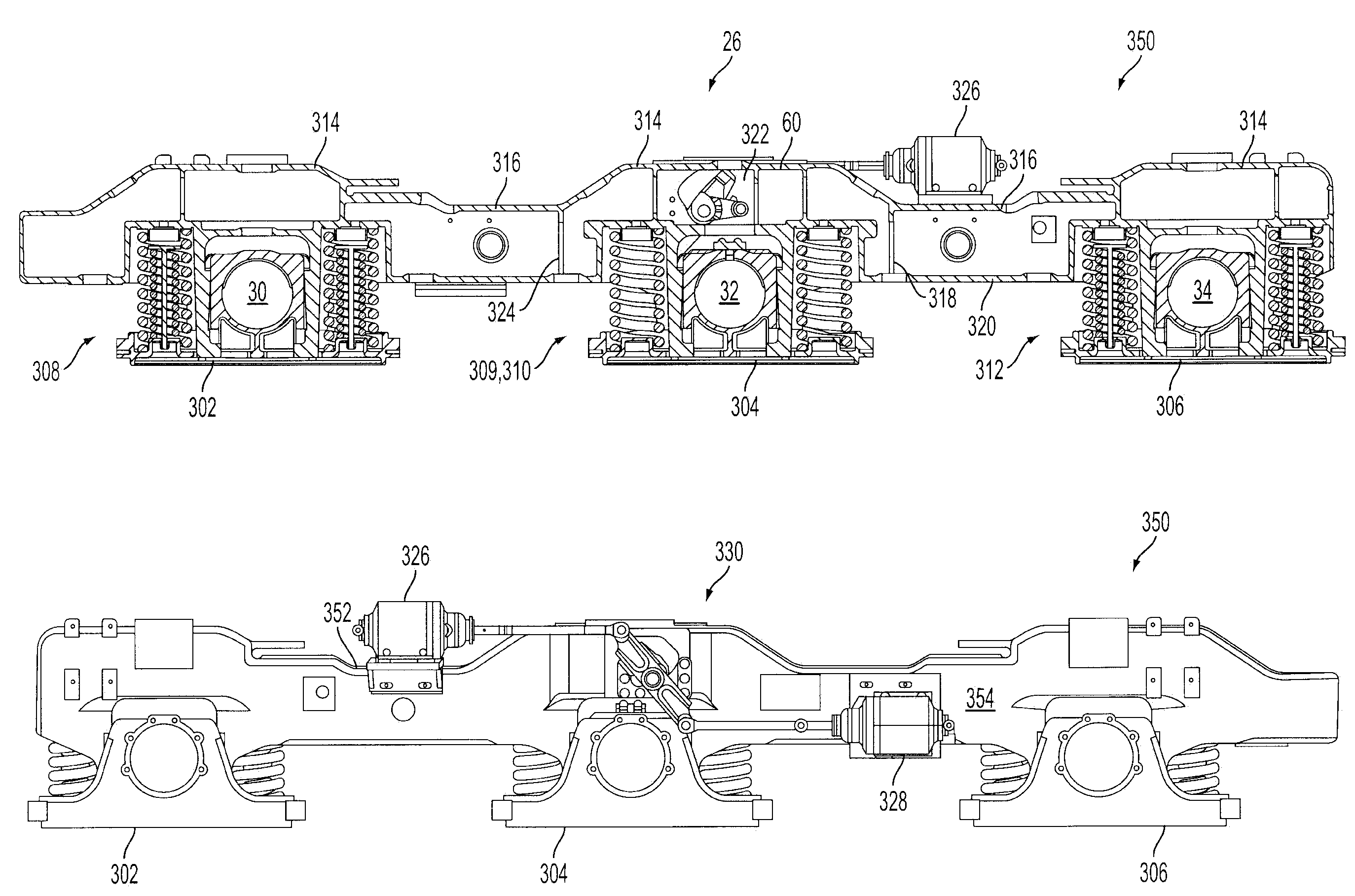

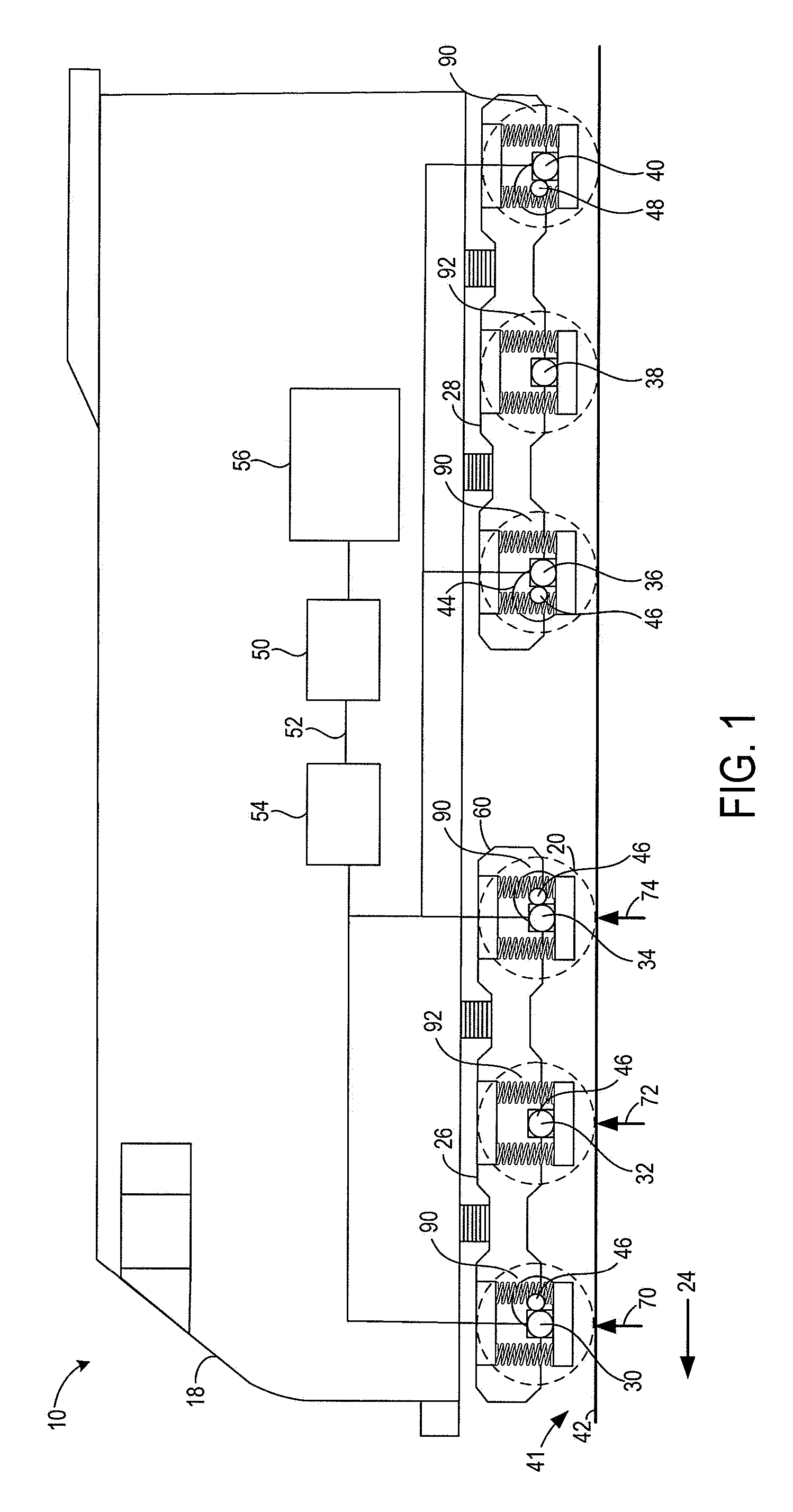

[0016]Embodiments of the invention may relate to a truck (or bogie) assembly, a vehicle having the truck assembly, and a method of operating the truck assembly. Vehicles, truck assemblies, systems and / or methods are provided for transferring weight among wheels and / or axles supporting the rail vehicle. As an example, the vehicle may be a locomotive or rail vehicle that can be positioned on a rail.

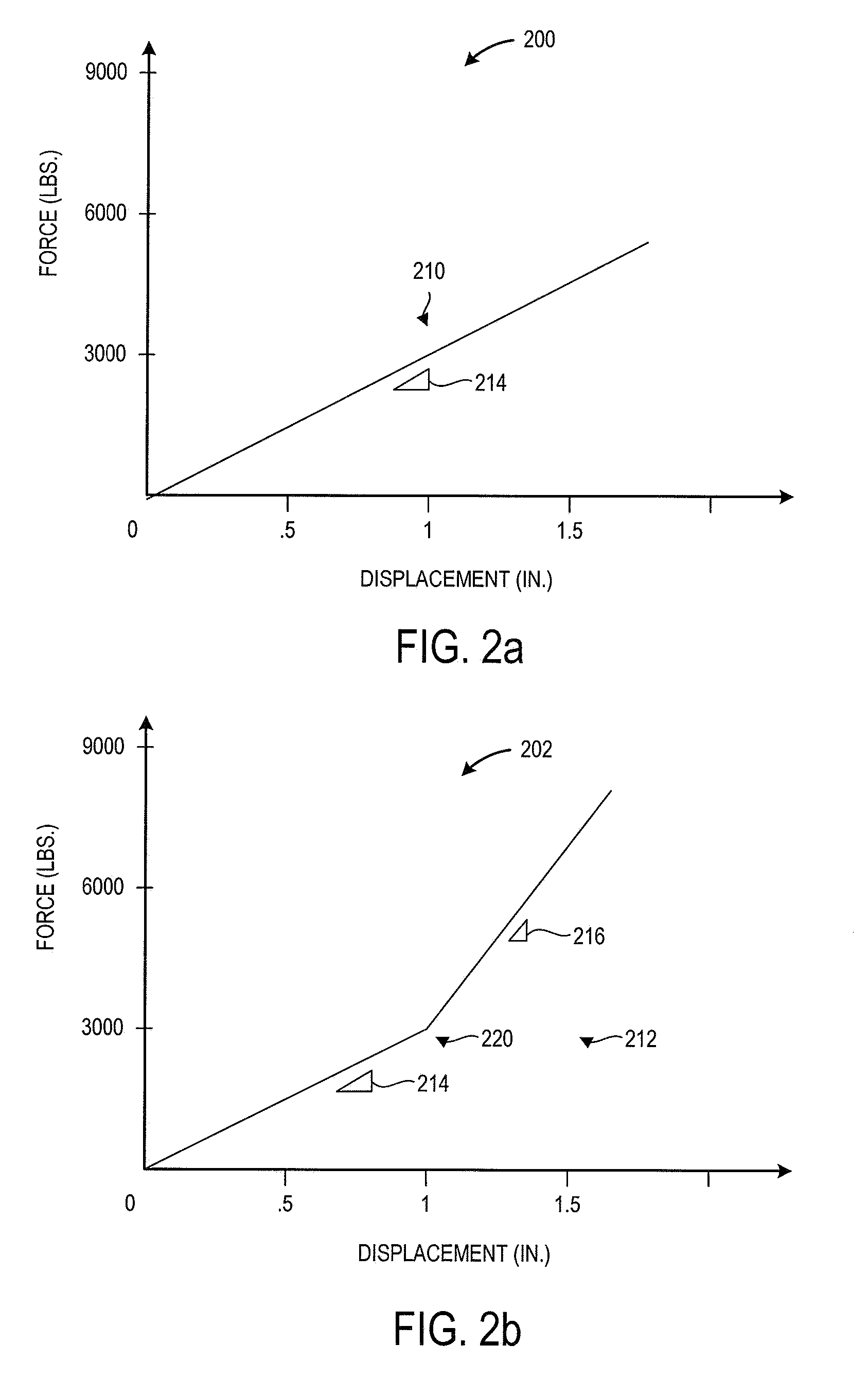

[0017]In one embodiment, an example method includes operating a vehicle having a suspension. The method may include operating the suspension in a first mode with a first effective suspension spring rate; and operating the suspension in a second mode with a second, different, effective suspension spring rate.

[0018]The suspension may comprise one or more springs, where the one or more springs together have an effective spring rate that varies with displacement of the suspension. In some conditions the rail vehicle selectively, and in some cases dynamically, increases normal force on the rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com