Heat dissipating structure and method of manufacturing same

a heat dissipating structure and heat dissipating technology, applied in the direction of heat transfer modification, indirect heat exchangers, light and heating apparatus, etc., can solve the problems of bringing hazards to human bodies, environmental pollution, environmental pollution, etc., and achieve good heat conducting and dissipating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

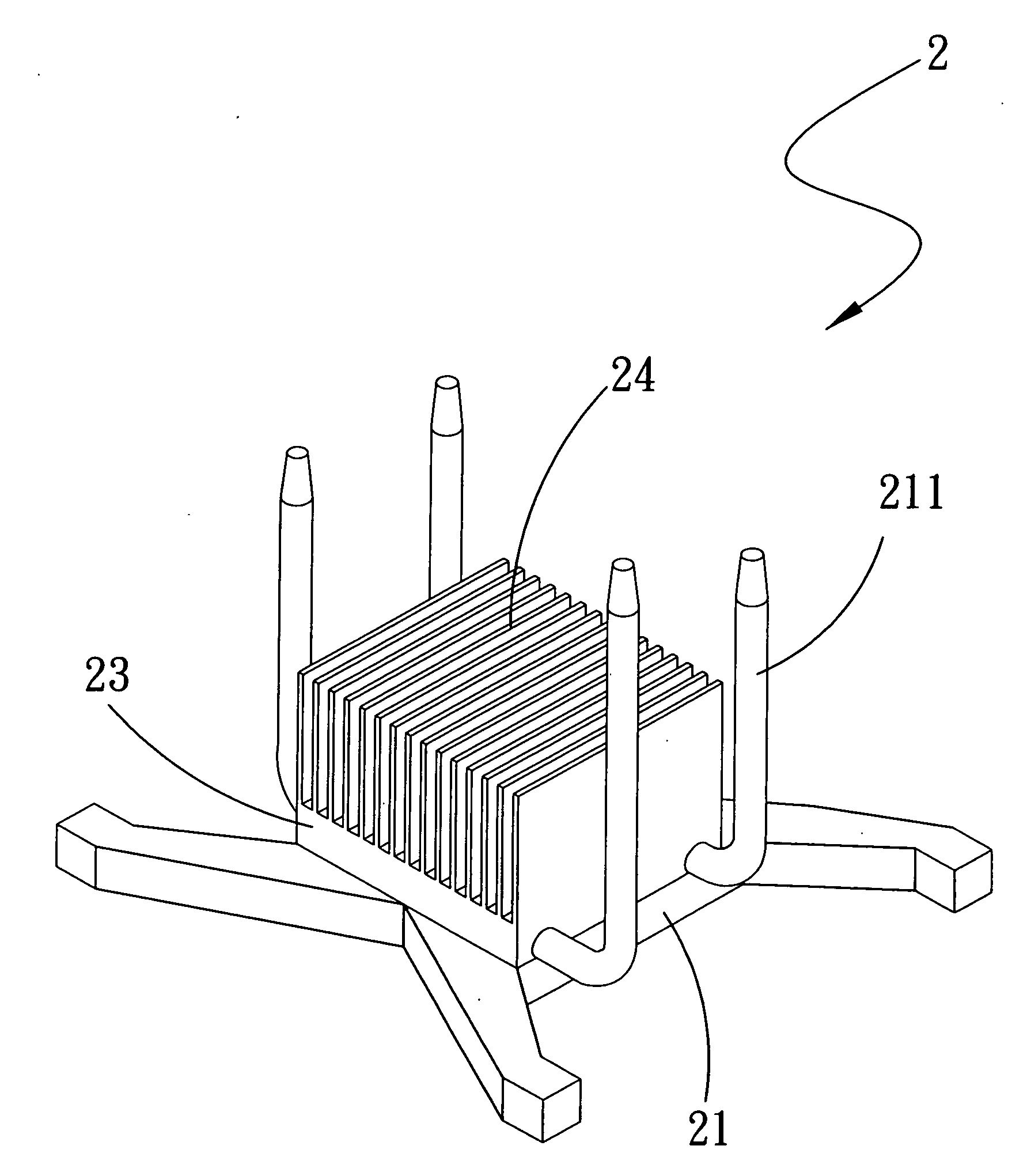

[0024]The present invention also provides a method of manufacturing the heat dissipating structure 2. Please refer to FIG. 7, in the method of manufacturing the heat dissipating structure 2 according to the present invention, the following steps are included:[0025]Step S11: positioning a plurality of heat pipes 22 in lower pipe-receiving grooves 211 formed on a base 21;[0026]Step S12: closing a cover 23 onto the heat pipes 22, so that upper pipe-receiving grooves 231 correspondingly formed on the cover 23 are engaged with the heat pipes 22;[0027]Step S13: applying a heat-conducting substance 3 between the heat pipes 22 and the base 21 and between the heat pipes 22 and the cover 23; and[0028]Step S14: pushing the cover 23 against the base 21 for them to tightly connect to each other and thereby fixedly hold the heat pipes 22 therebetween.

[0029]The heat dissipating structure 2 formed through above-described steps has tightly closed and connected base 21 and cover 23 while the heat pip...

second embodiment

[0030]In the method of manufacturing the heat dissipating structure 2 according to the present invention as shown in FIG. 8, the following steps are included:[0031]Step S21: applying a heat-conducting substance 3 in lower pipe-receiving grooves 211 formed on a base 21;[0032]Step S22: positioning a plurality of heat pipes 22 in the lower pipe-receiving grooves 211 on the base 21;[0033]Step S23: applying a heat-conducting substance 3 in upper pipe-receiving grooves 231 formed on a cover 23;[0034]Step S24: closing the cover 23 onto the heat pipes 22 with the upper pipe-receiving grooves 231 engaging with the heat pipes 22;[0035]Step S25: pushing the cover 23 against the base 21 for them to tightly connect to each other and thereby fixedly hold the heat pipes 22 therebetween.

[0036]In forming the heat dissipating structure 2 through the above-described steps, the heat-conducting substance 3 is first applied in the lower and upper pipe-receiving grooves 211, 231 on the base 21 and the cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com