Micro-channel heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Various embodiments of the micro-channel heat exchanger of the present invention will be described in conjunction with the accompanying drawings. It shall be noted that various embodiments described below are only for illustration of the present invention but not intended to limit the present invention.

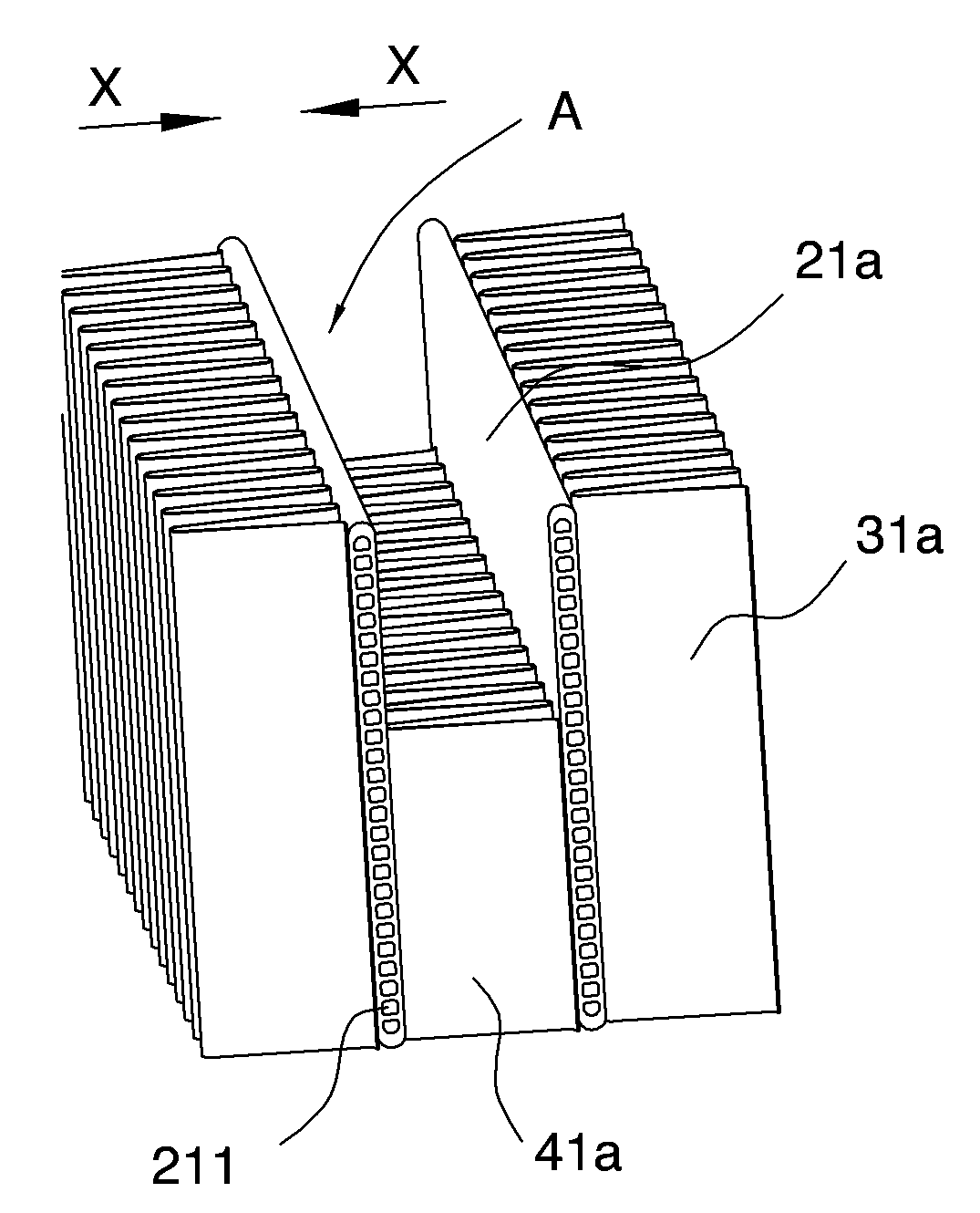

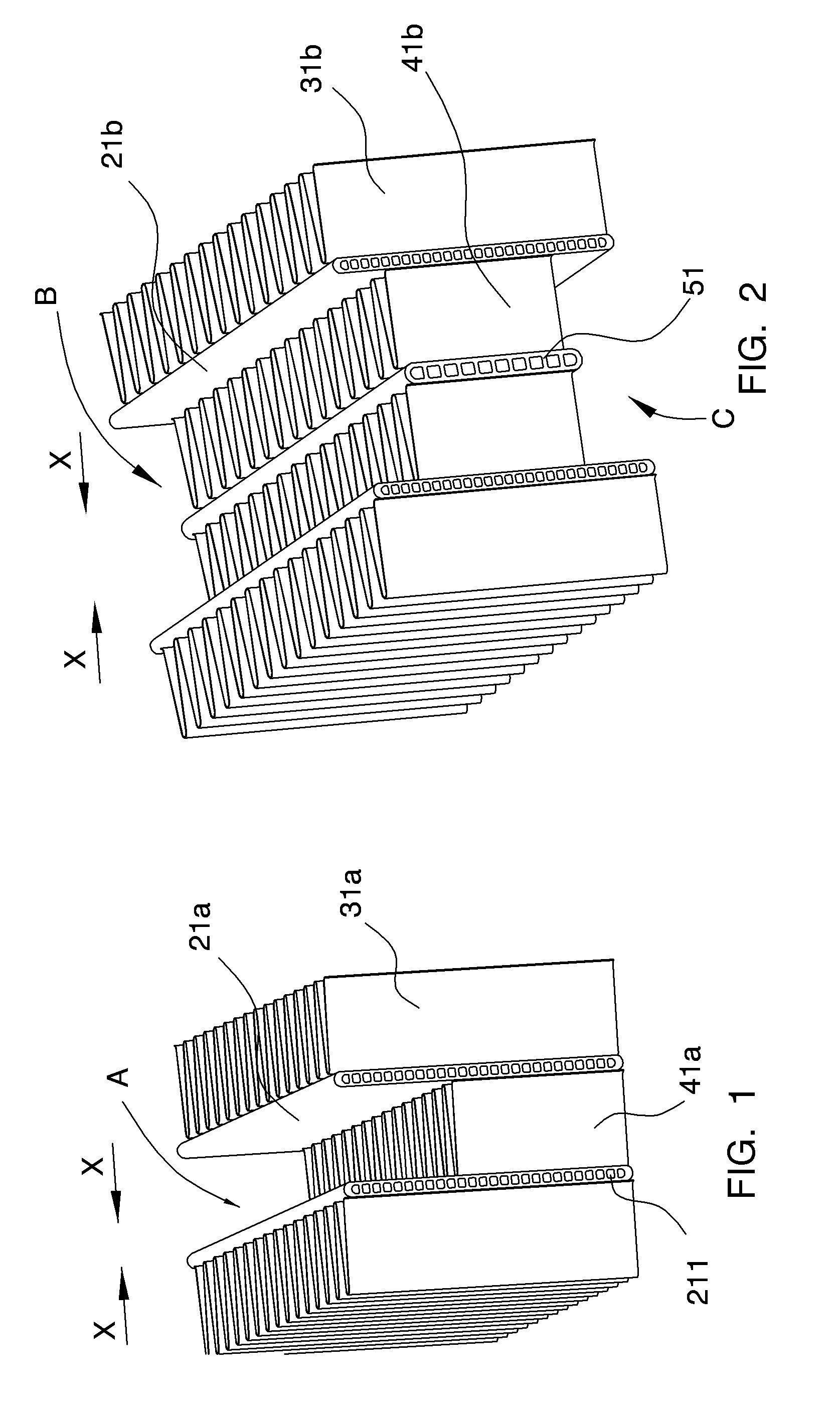

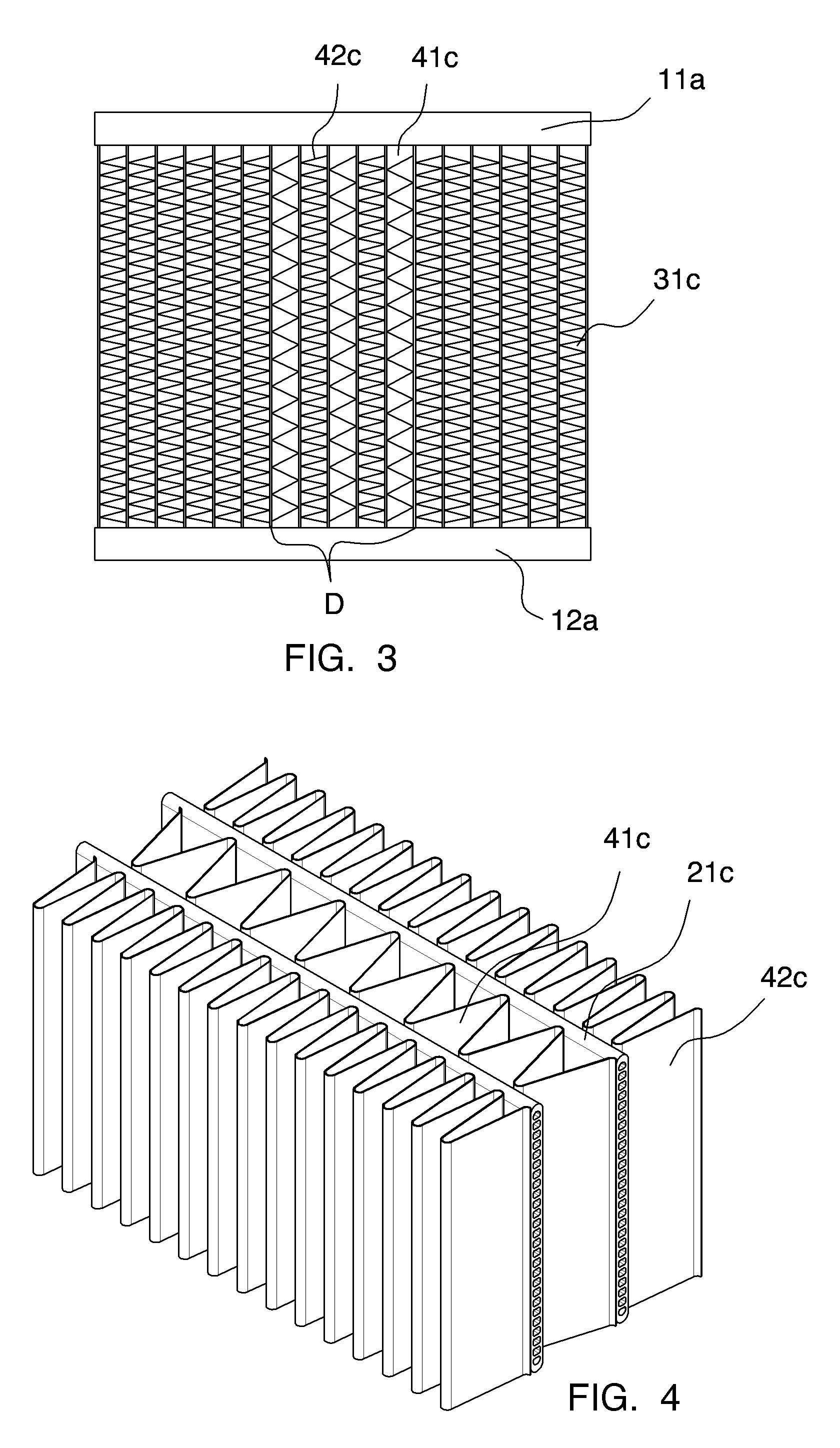

[0022]FIG. 1 is a partial perspective view of a first preferable embodiment of the micro-channel heat exchanger of the present invention. A micro-channel heat exchanger in accordance with the present invention typically comprises an upper manifold 11a, a lower manifold 12a (see FIG. 3), a plurality of micro-channel flat tubes 21a respectively connected to the upper manifold 11a and the lower manifold 12a, and a plurality of rows of fins 31a spaced apart by the micro-channel flat tubes 21a. Both ends of each micro-channel flat tube 21a are respectively inserted into the interiors of the upper manifold 11a and the lower manifold 12a and are fixed with the upper and lower manifolds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com