Compact Vacuum Material Handler

a vacuum material and handler technology, applied in the direction of positive displacement liquid engines, couplings, fluid couplings, etc., can solve the problems of not being able to move from one piece of equipment to another with the material held in place, and the application of prior art vacuum material handlers has been limited, so as to achieve the effect of reducing additional cost, weight and siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

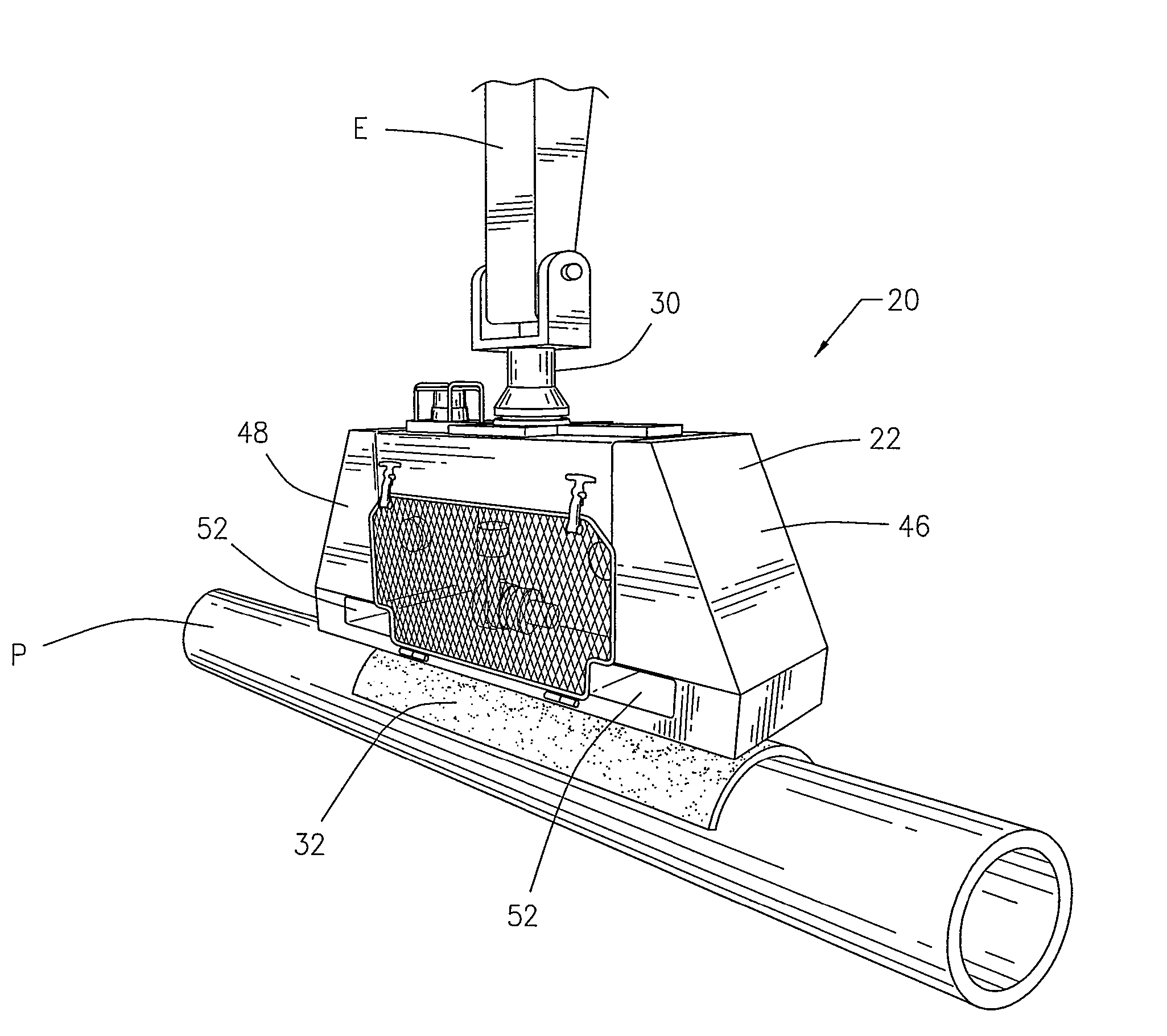

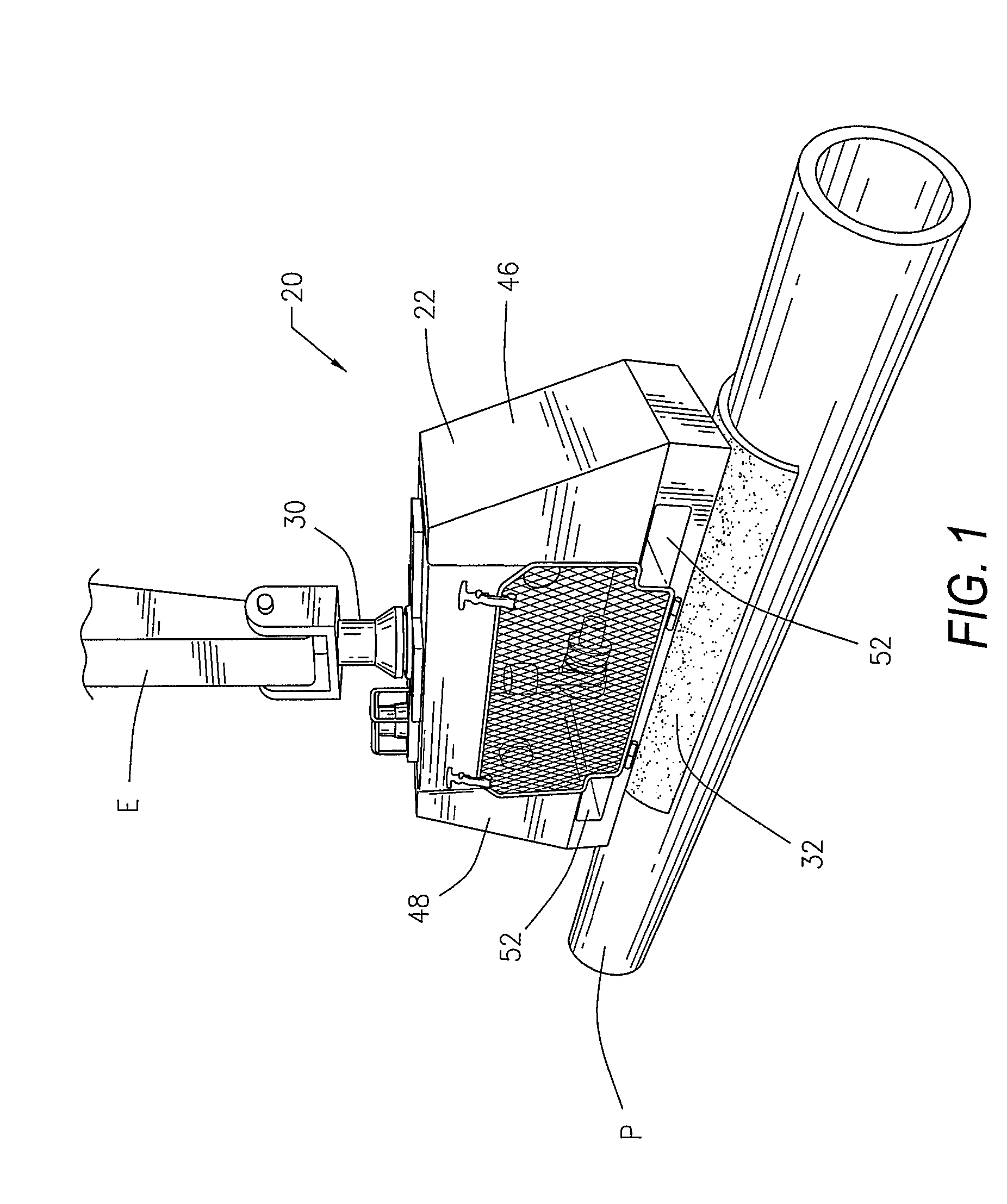

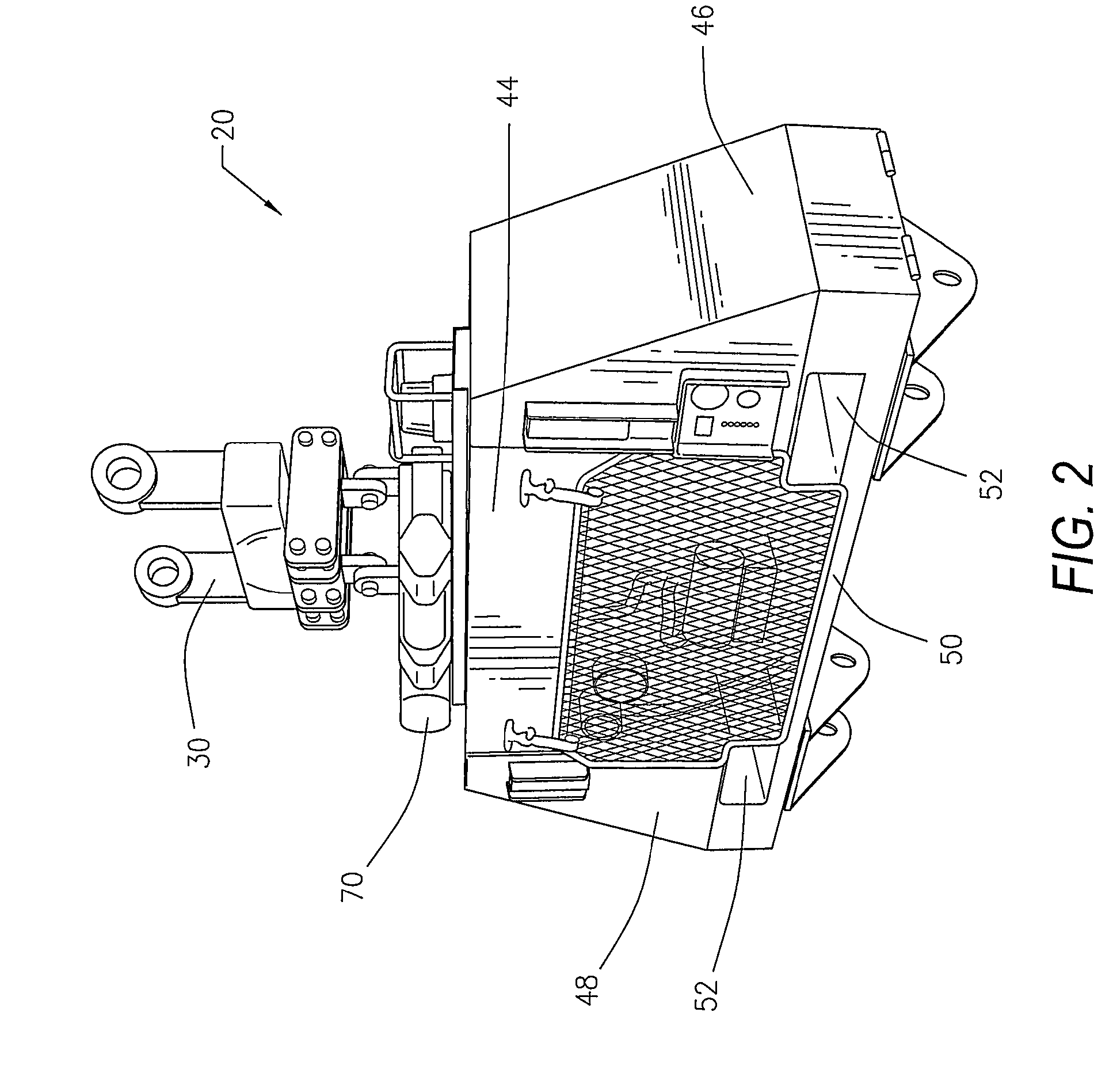

[0023]Turning now to FIGS. 1 through 6, the compact vacuum material handler of the present invention 20 has a frame 22, onboard drive engine 24, onboard vacuum pump 26, onboard hydraulic pump 28, rotator 30 and pads 32. When in use the vacuum material handler 20 can be coupled to an excavator, boom, backhoe or other equipment E by connecting it to the rotator 30. The material handler 20 can also be used in connection with a crane or other hoist by replacing the rotator 30 with a pick eye (not shown). When the material handler 20 is mounted to a excavator or other equipment E it can be used to pick up sheet metal, pipe P or other large items with a relatively smooth and uniform surface. The operator of the excavator lowers the vacuum handler 20 until the pads 32 come into contact with the pipe P or other material to be lifted.

[0024]Once the pads 32 are in contact with the pipe P the vacuum solenoid 18 opens placing the pads in fluid communication with the vacuum reservoir 54 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com