Water pump

a water pump and pump body technology, applied in the field of water pumps, can solve the problems of high construction cost, high construction cost, and high cost of transportation, shipping and construction, and achieve the effects of less equipment, convenient work, and affordable access to safe water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

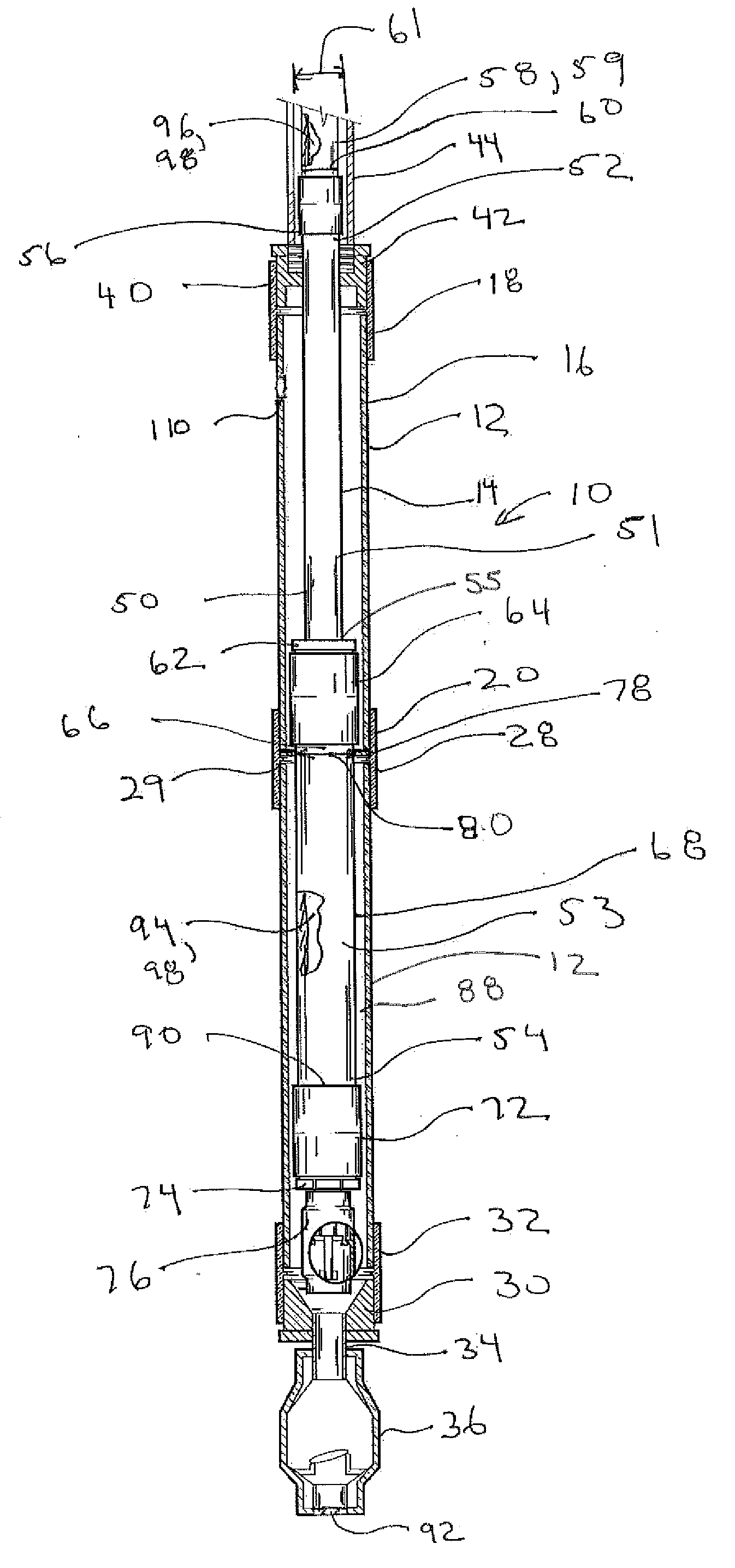

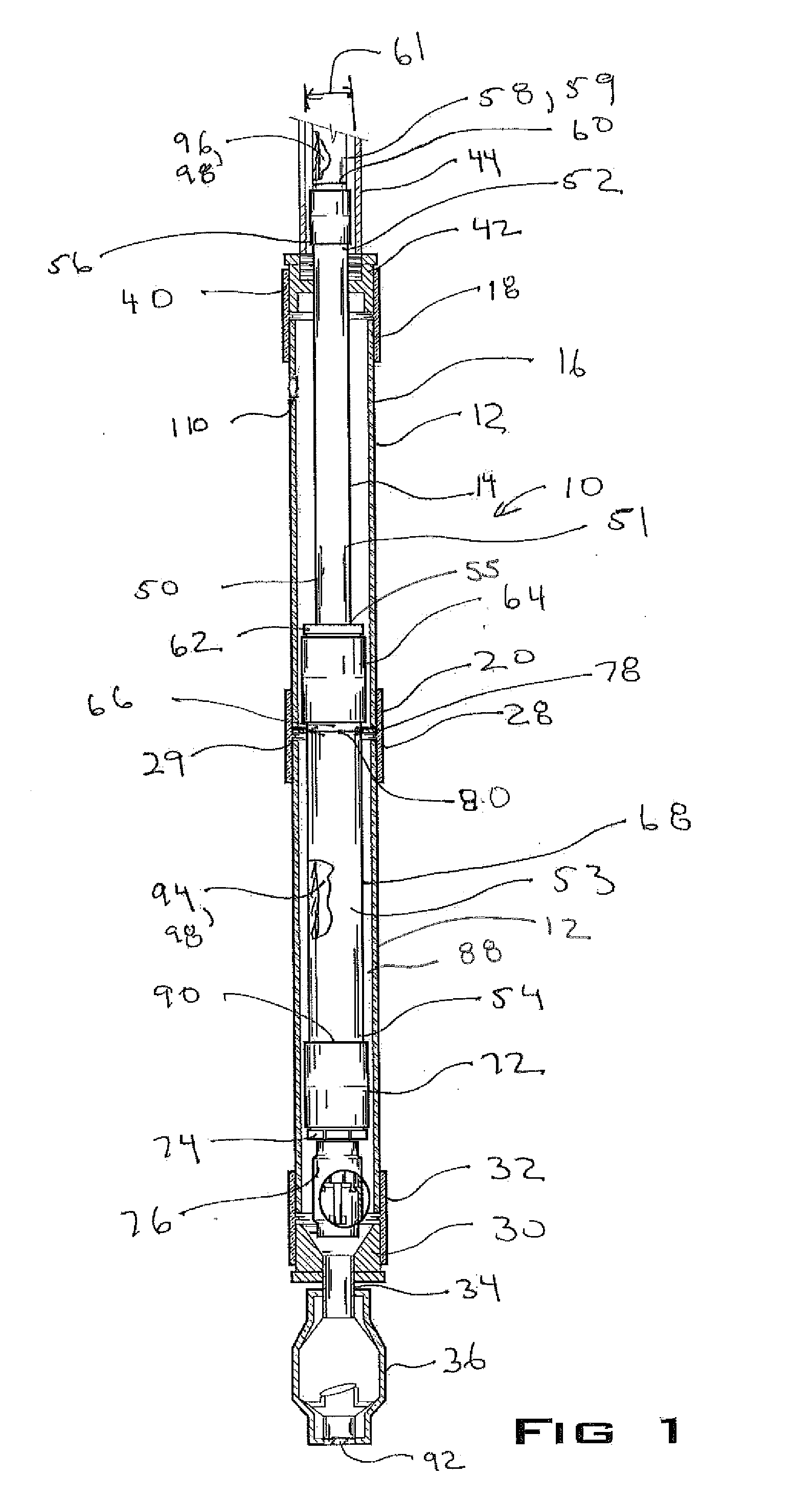

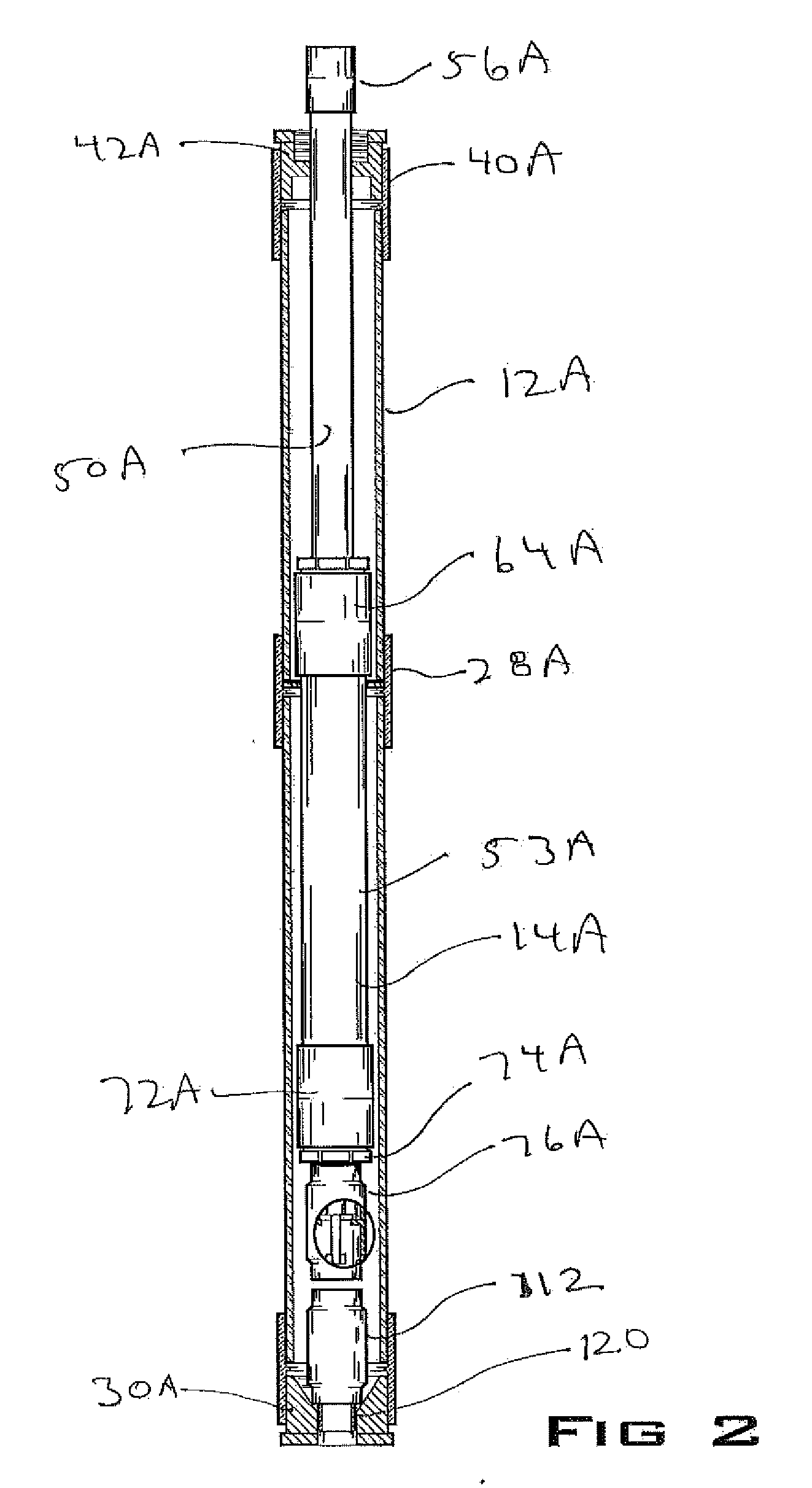

[0012]The water pump 10 of the current disclosure comprises a housing 12 with a plunger assembly 14 disposed therein. Housing 12 includes an upper, or guide cylinder 16 having upper end 18 and lower end 20 connected to a lower, or pressure cylinder 22 having upper and lower ends 24 and 26, respectively. Lower end 26 of pressure cylinder 22 may be referred to as the first end thereof, and is also the first, or lower end of housing 12. Guide cylinder 16 is connected to pressure cylinder 22 with a coupling 28. Guide cylinder 16, pressure cylinder 22 and coupling 28 may be, for example, PVC, and may be connected with adhesives, or may be threadedly connected. Coupling 28 has a radially inwardly extending shoulder 29 positioned between lower end 20 of guide cylinder 16, and upper end 24 of pressure cylinder 22.

[0013]A reducer bushing 30 is connected to pressure cylinder 22 at the lower end 26 thereof with a coupling 32. A nipple, or pipe stub 34 is attached to reducer bushing 30, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com