Composite steel claded mill liner

a technology of composite steel and mill liner, which is applied in the direction of instruments, foundry patterns, and moulding apparatus of foundries, can solve the problems of finer particles grinding, material individual limitations, and degradation of grinding media and drum liner, and achieve the effect of extending the wear life cycl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

:

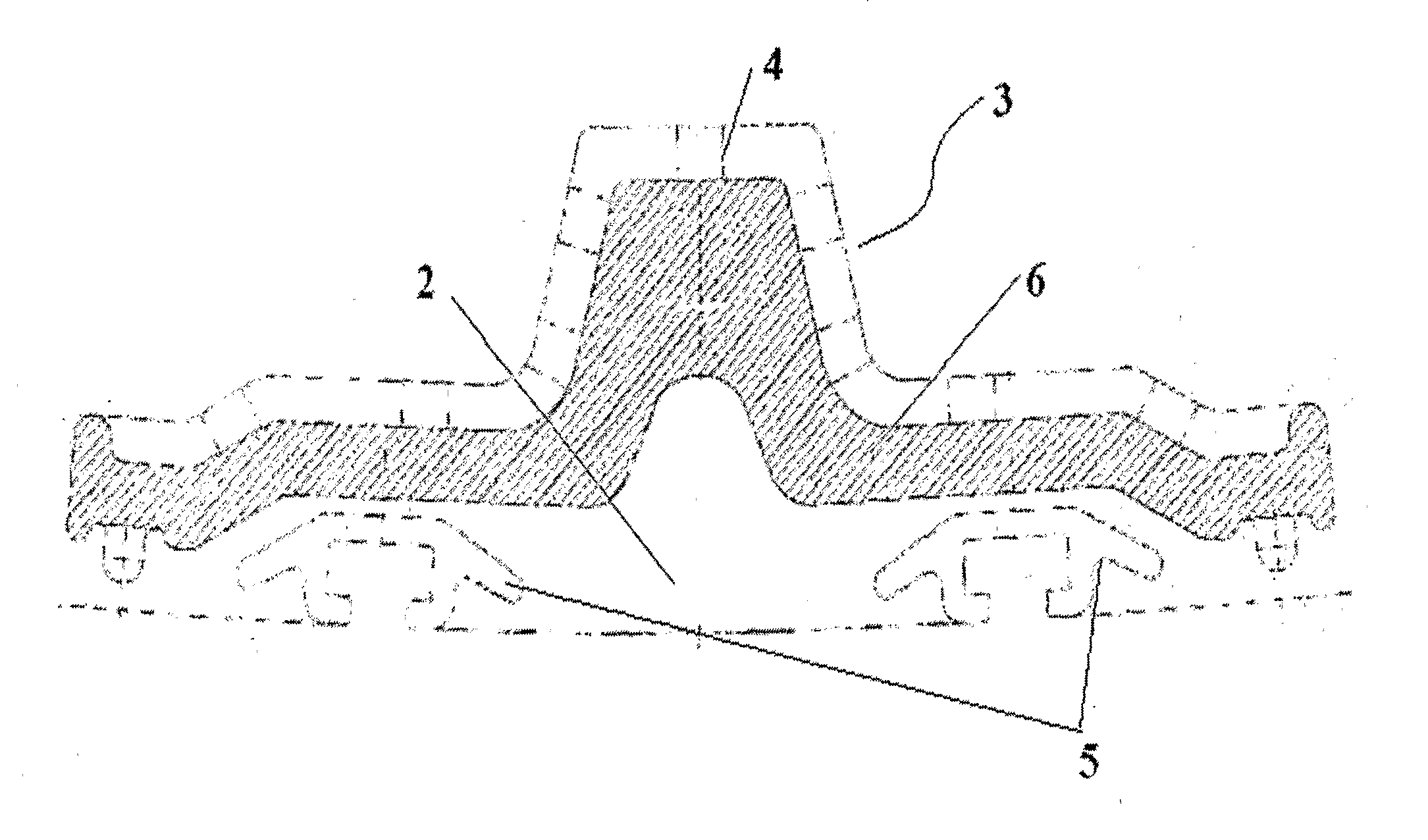

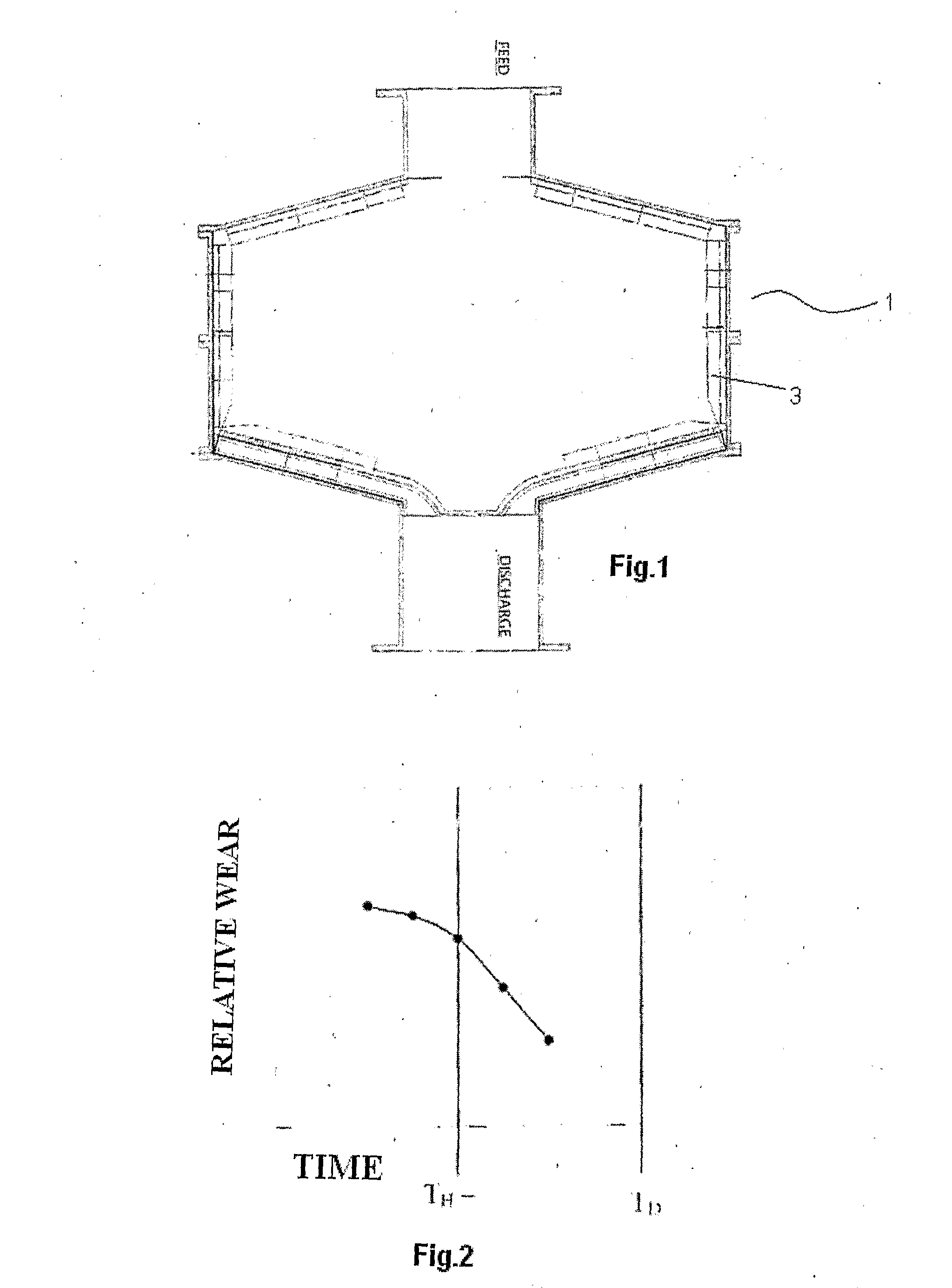

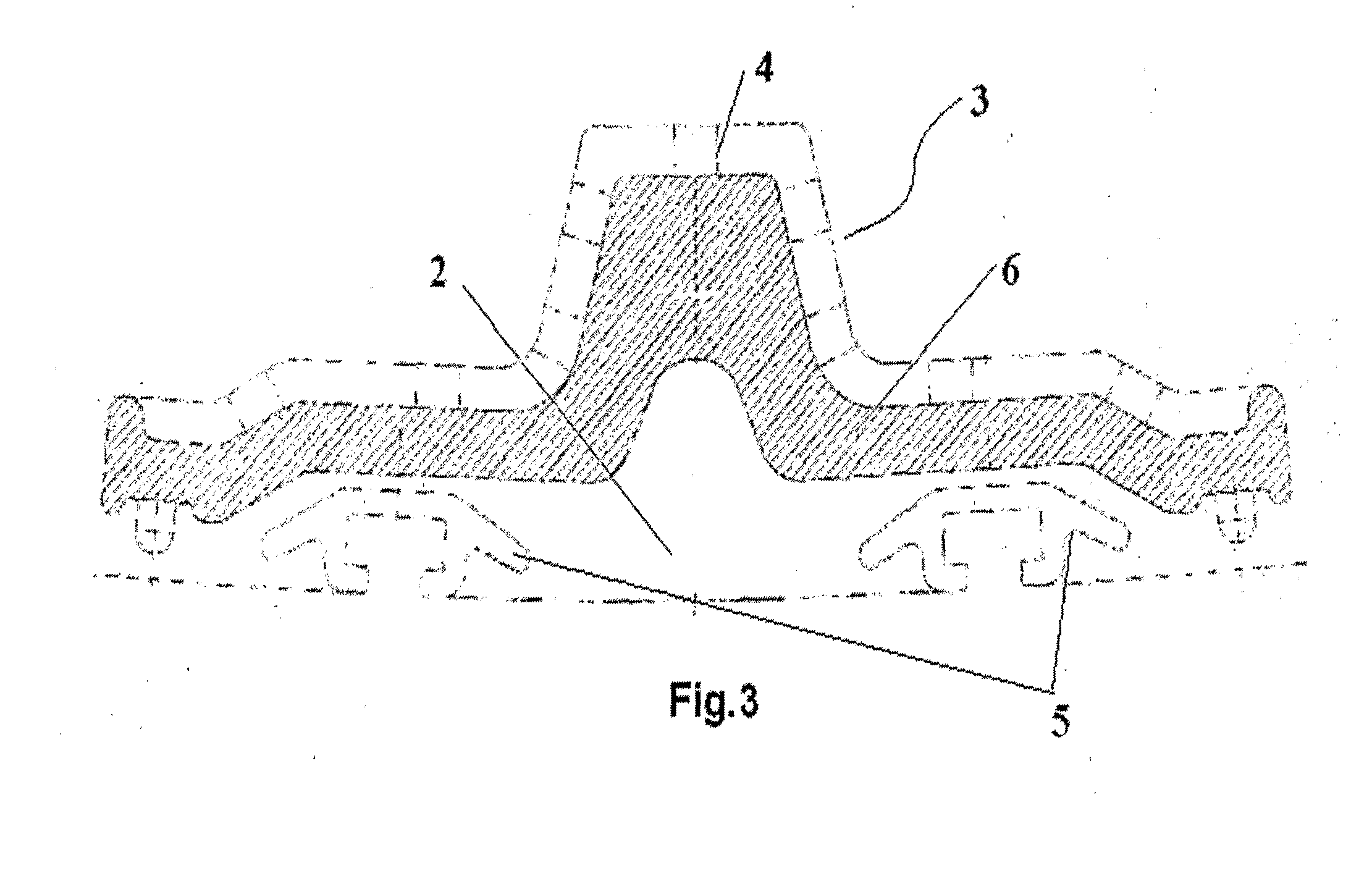

[0029]According to the invention, a symmetrically distributed soft rubber backing on a composite liner system, as shown in FIG. 1 is disclosed. The inside wall of the shell of the grinding mill, (1) is retrofitted with a rubber backed composite mill liner (3). The liner has a top layer made of cast steel. An example of the inventive liner is chrome-moly cast steel layer with integrated rubber back layer. Natural rubber can be used to make the rubber layer. These two layers make an integrated system of rubber backing and composite lining. The two layers are joined together by hot vulcanization in course of transfer moulding.

[0030]The inventive liner has done away with the present concept of fixing lifter bars on the shell. Instead the instant liner is an integrated single profile of bar or bars and plate or plates. Therefore, independent of any number of holes available in a row but depending only on the number of lifts required for a specific application individual profile can be d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap