Sheet Metal Panel Shape for Low Sound Radiation

a sheet metal panel and low sound radiation technology, applied in the direction of transportation and packaging, mechanical equipment, layered products, etc., can solve the problems of vibrational energy of sheet metal panels and sound emission from body panels, and achieve the effect of reducing or eliminating, reducing sound radiation, and reducing sound radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

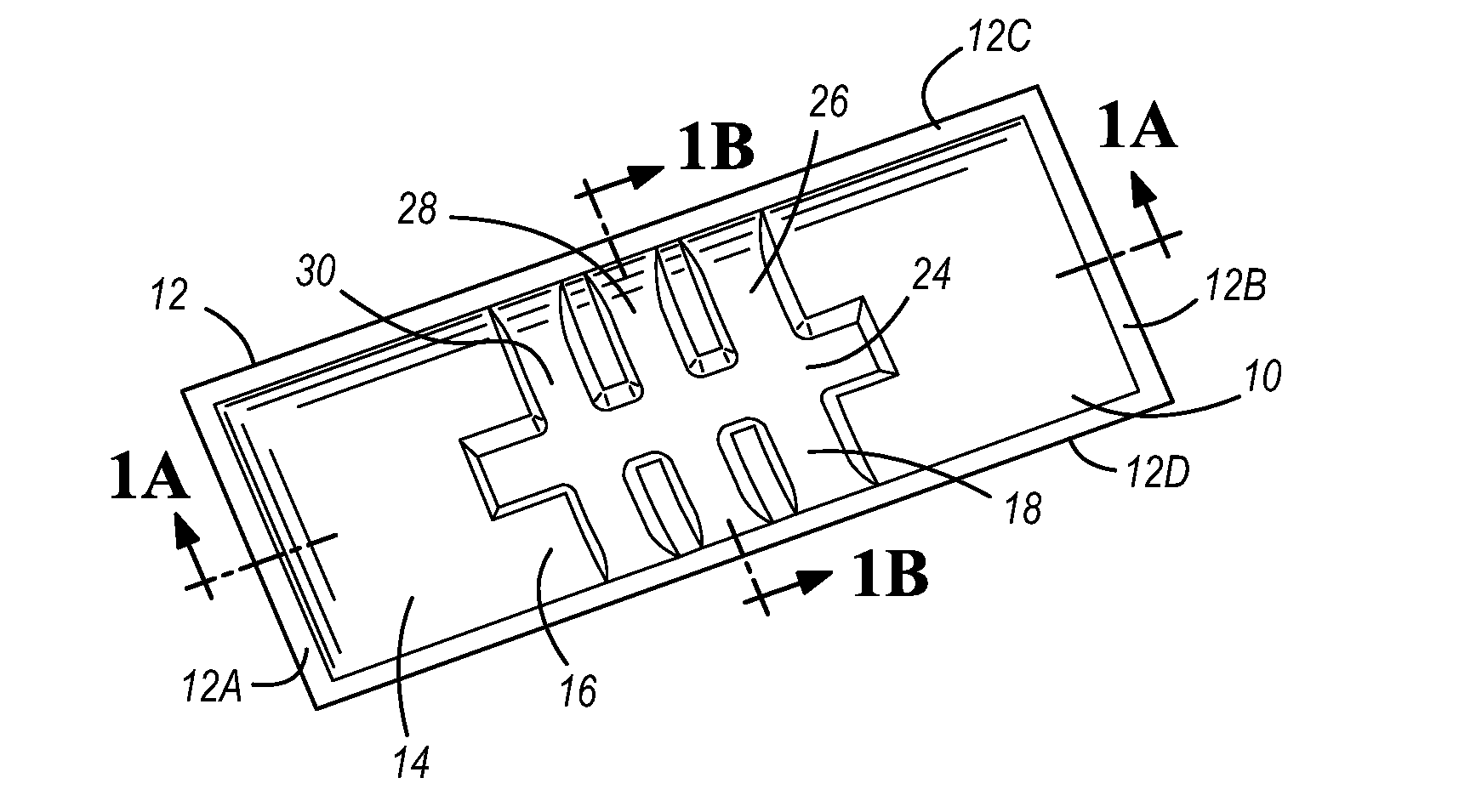

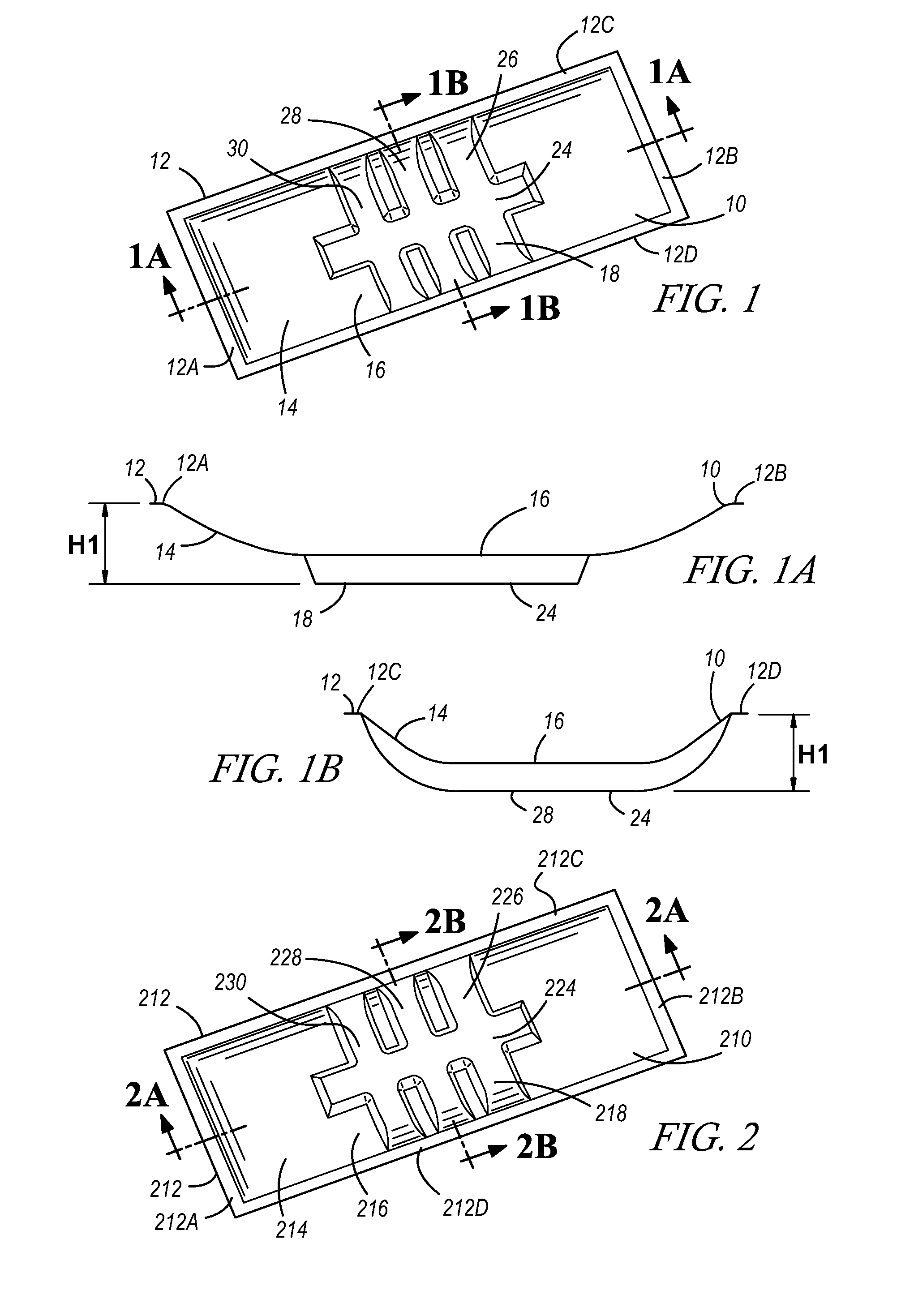

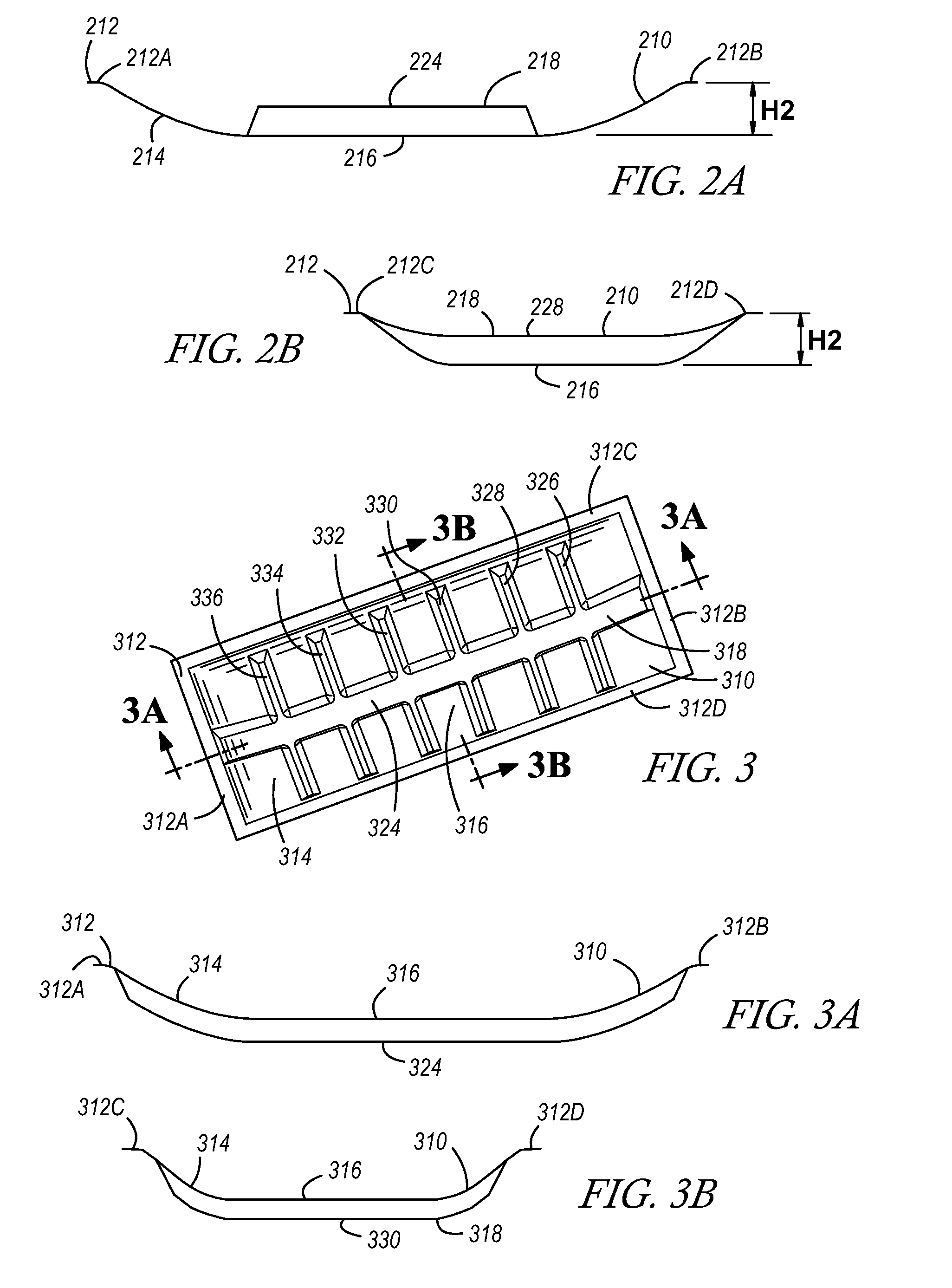

[0029]Referring to FIGS. 1, 1A, and 1B, it is seen that a sheet metal panel 10 is provided and includes a peripheral flange 12, a crown 14, a flat 16 and a bead pattern 18. The flange 12 defines the outer edge of the panel 10 and generally bounds the four sides of the crown 14. Panel 10 is shown to be generally rectangular in shape and thus the flange 12 can be seen to include end flanges 12A and 12B and side flanges 12C and 12D. The flange 12 enables the panel 10 to be welded to adjacent panels, or the panel 10 can be integral with the adjacent panels and stamped in one piece therewith. As seen in FIGS. 1A and 1B, the flange 12 is preferably in a single plane. Sheet metal panel 10 is made in a sheet metal stamping process in which the panel 10 is shaped between an upper die and a lower die which form the shape of the panel 10 including the flange 12, crown 14, flat 16 and the bead pattern 18.

[0030]As best seen in FIGS. 1A and 1B, the crown 14 is a curvilinear or bulged shape that e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| vibrational energy | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com