EXHAUST AFTERTREATMENT SYSTEMS FOR GASOLINE AND ALTERNATIVE-FUELED ENGINES, WITH REDUCTION OF HC, CO, NOx, AND PM

a technology of exhaust aftertreatment and gasoline, which is applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve the problems of no pm emission regulation, small diameter pm is more harmful to health, and the improvement of emissions has not met the emission limi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The following description is directed to emissions aftertreatment systems for use in the exhaust system of a spark-ignited engine. Examples of spark-ignited engines other than gasoline engines are alternative-fueled engines, such as engines fueled by compressed natural gas (CNG), liquefied natural gas (LNG), liquefied petroleum gas (LPG), ethanol, methanol, gas-to-liquid fuel, and coal-to-liquid fuel, and others.

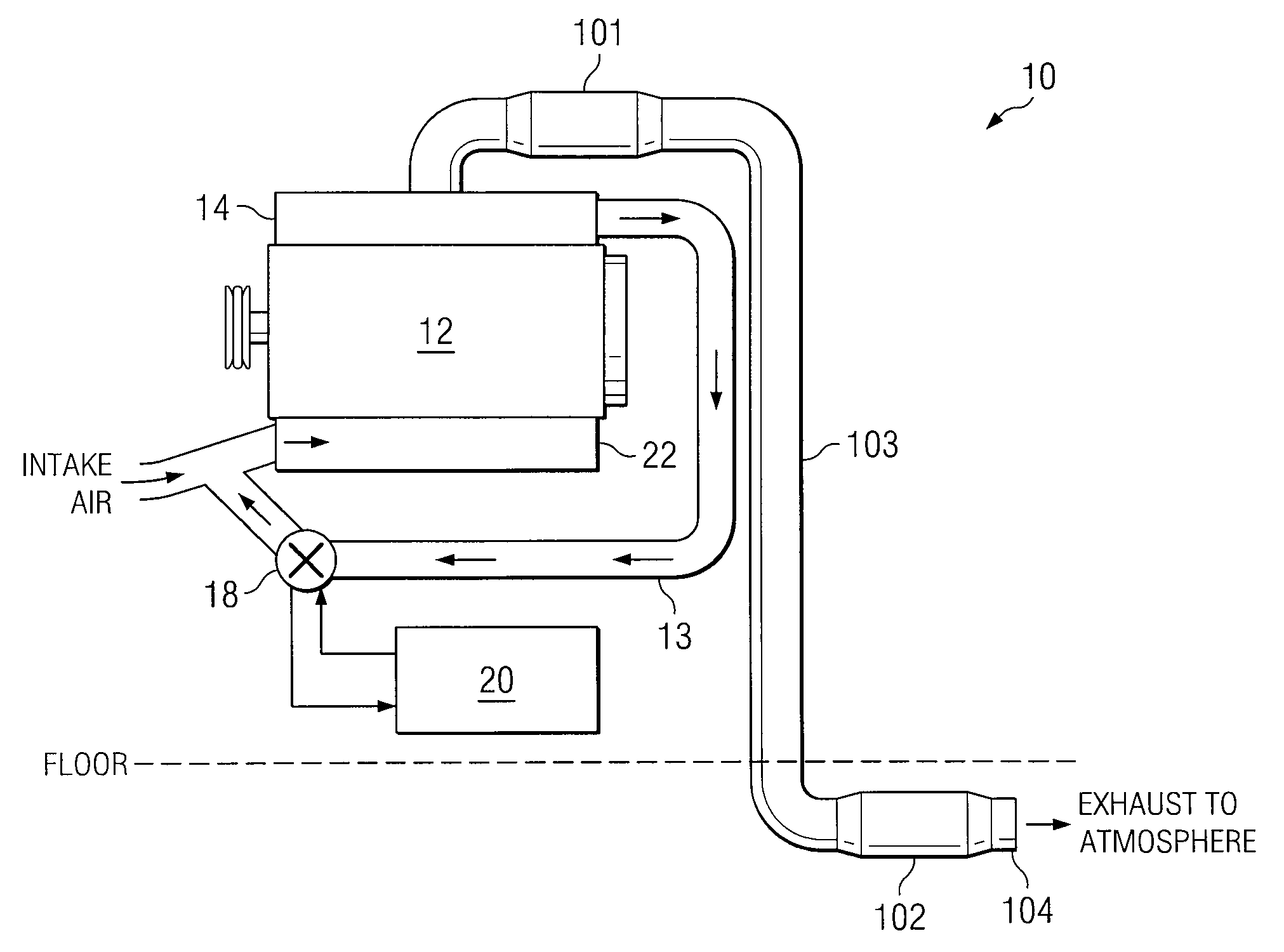

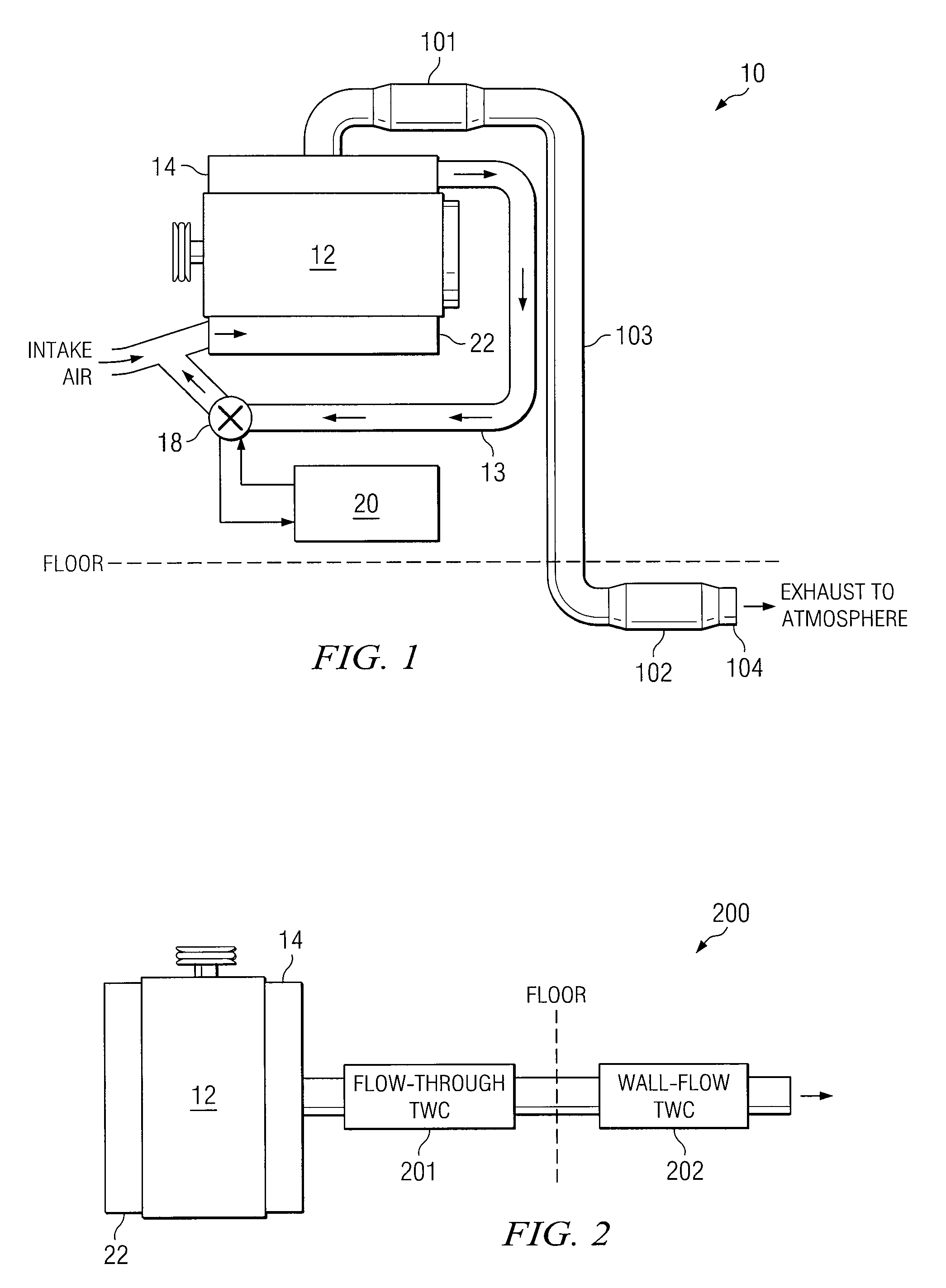

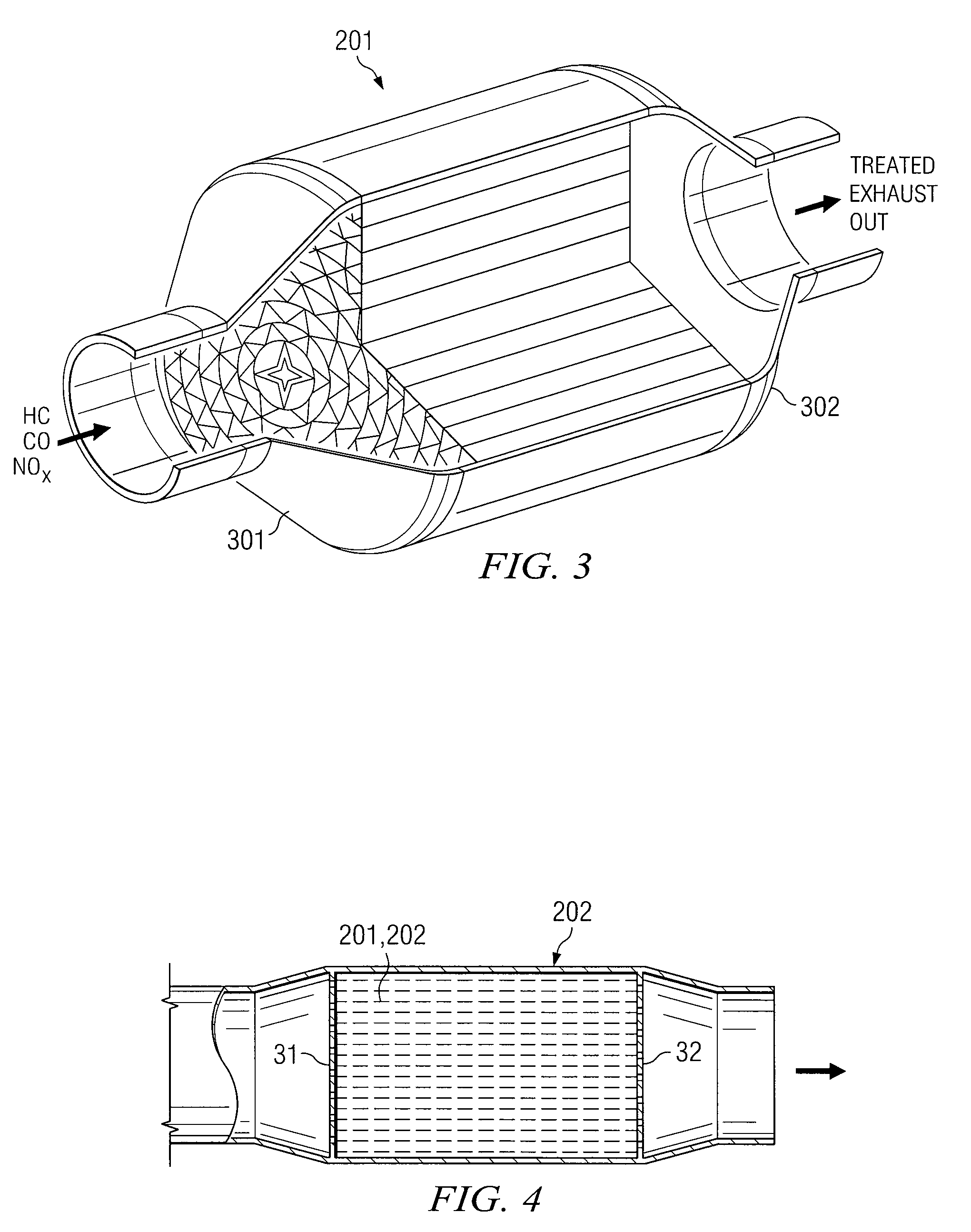

[0015]Typical applications of the exhaust aftertreatment systems described herein are with vehicles, such as automobiles, which have an engine compartment, a driver / passenger compartment with a floor above the axles and wheels, and an under-floor tailpipe. The aftertreatment systems described herein simultaneously reduce emissions of hydrocarbon (HC), carbon monoxide (CO), oxides of nitrogen (NOx) and particulate matter (PM).

[0016]FIG. 1 illustrates a spark-ignited engine system, generally identified as 10, having a “close-coupled” emissions treatment device 101 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com