Apparatus for mounting a load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

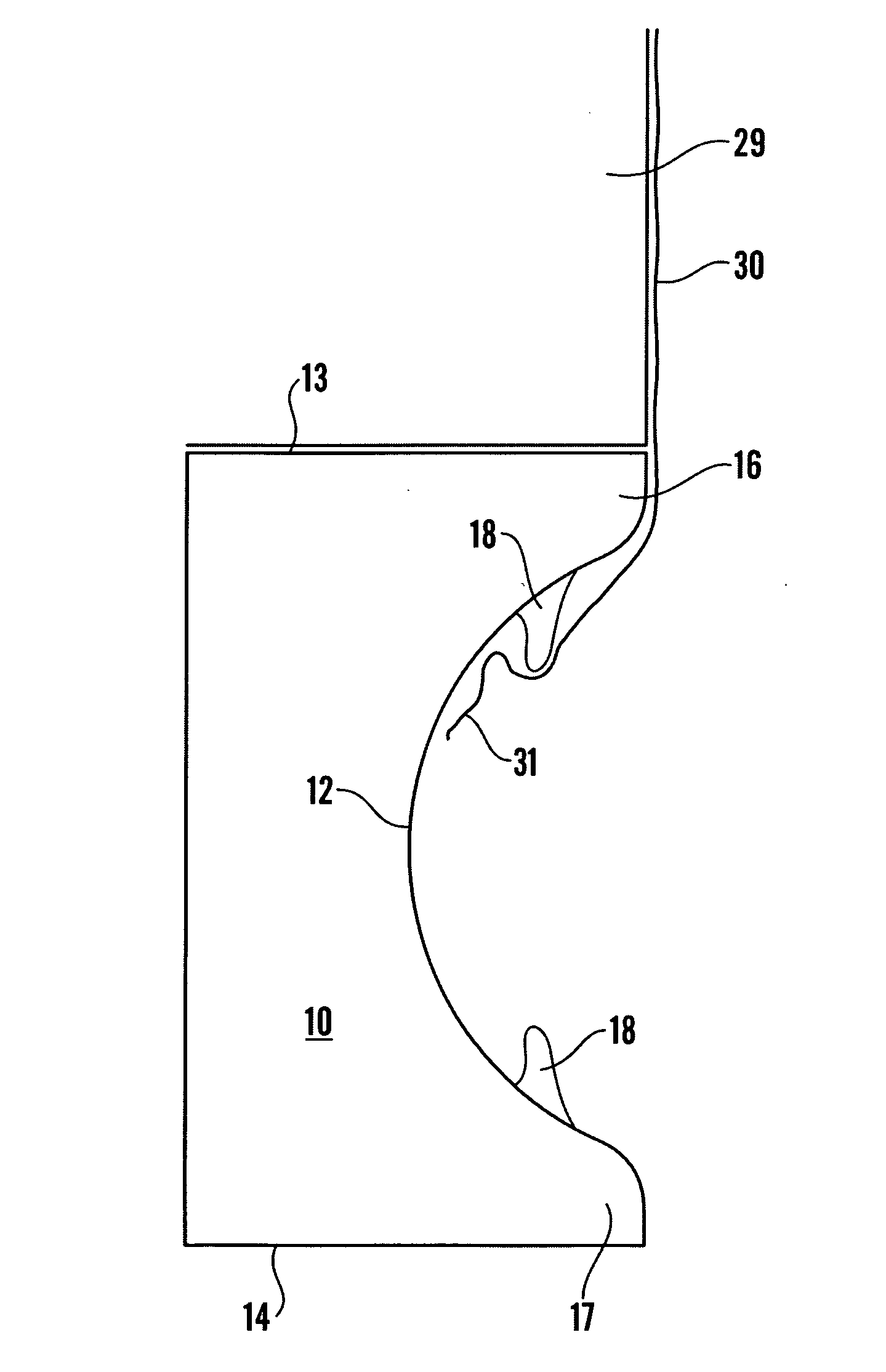

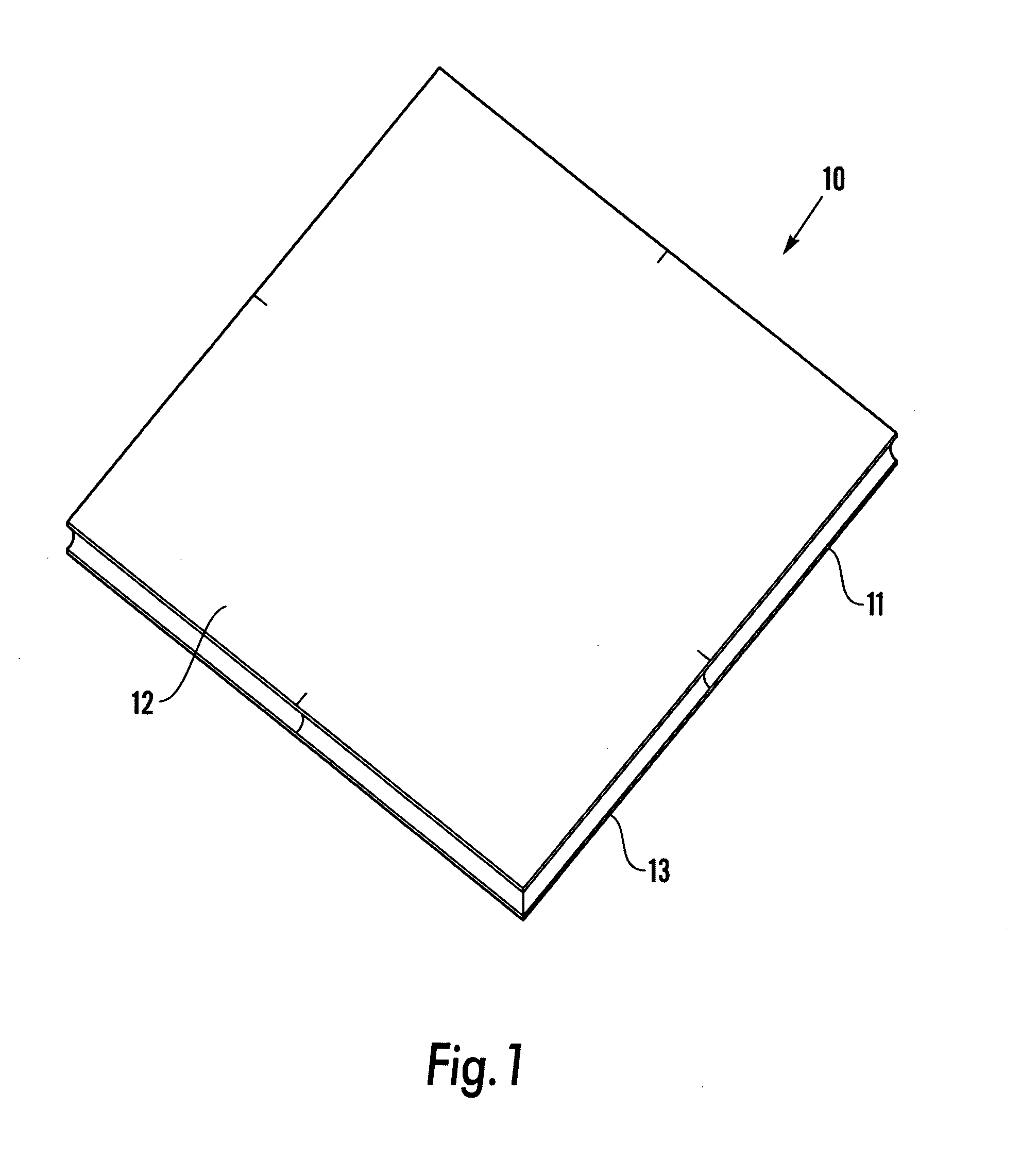

[0024]Referring to FIG. 1 there will be seen a deck 10 comprising a rectangular sheet. The deck 10 may preferably be of a plastic material and is preferably of injection moulded plastic. The plastic material is selected for the use envisaged and may be high density polyethylene or polypropylene. It may however be of other material such as wood or plywood.

[0025]The deck may have dimensions appropriate to its use which is typically 1200 mm×1000 mm and of a thickness of 45 mm in the UK, typically 1200 mm×800 mm and of a thickness of 45 mm in Europe, typically 1220 mm×1016 mm and of a thickness of 45 mm in the US and typically 1100 mm×1100 mm and of a thickness of 45 mm in Japan. The thickness may vary depending on the load to be mounted on the deck.

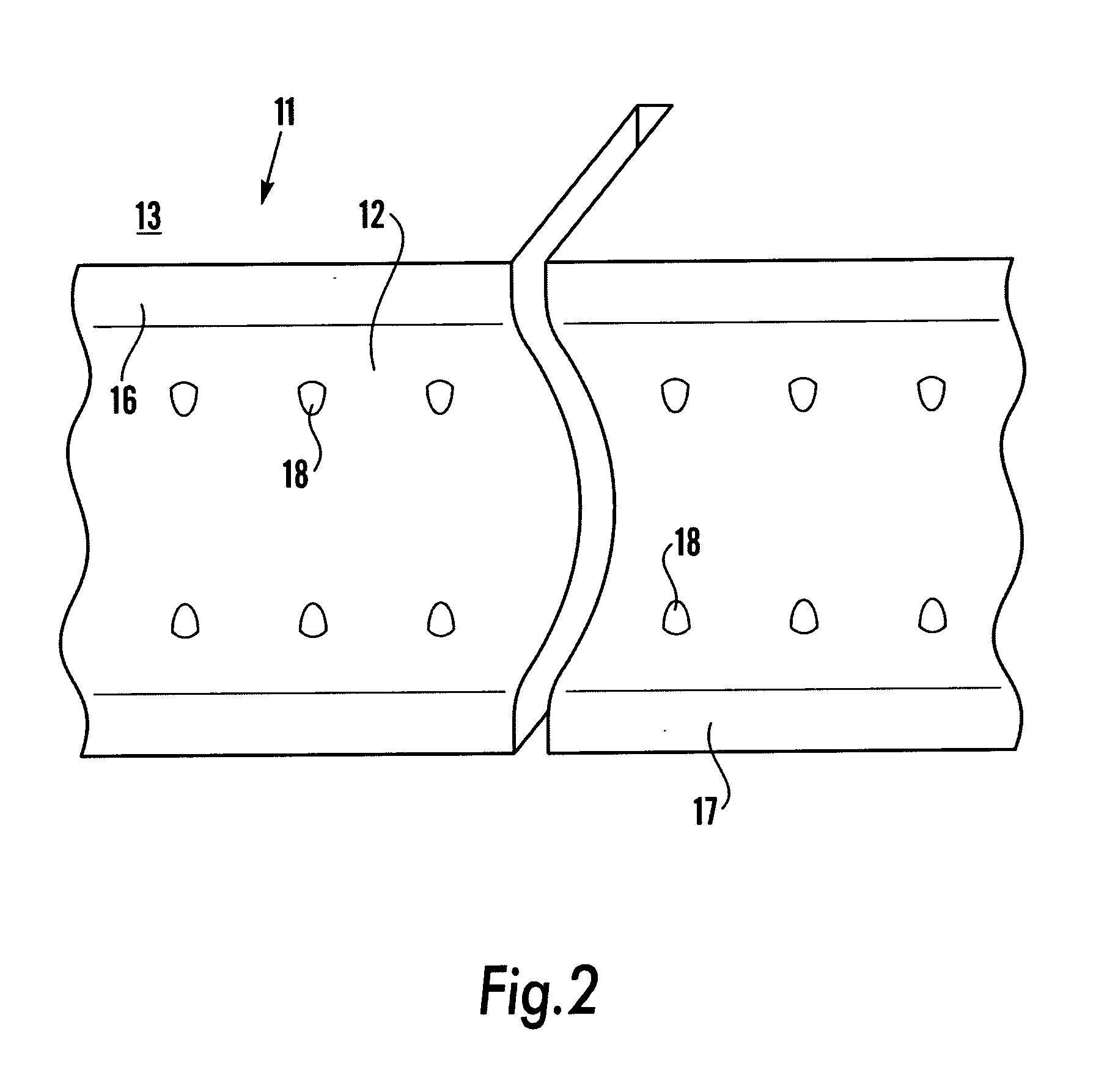

[0026]FIG. 2 shows a perspective side view of part of the deck 10 and as can be seen each edge 11 of deck 10 has a channel in the form of a concave section 12. However other cross section channels are envisaged including V section channels. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com