Flow diverter for drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

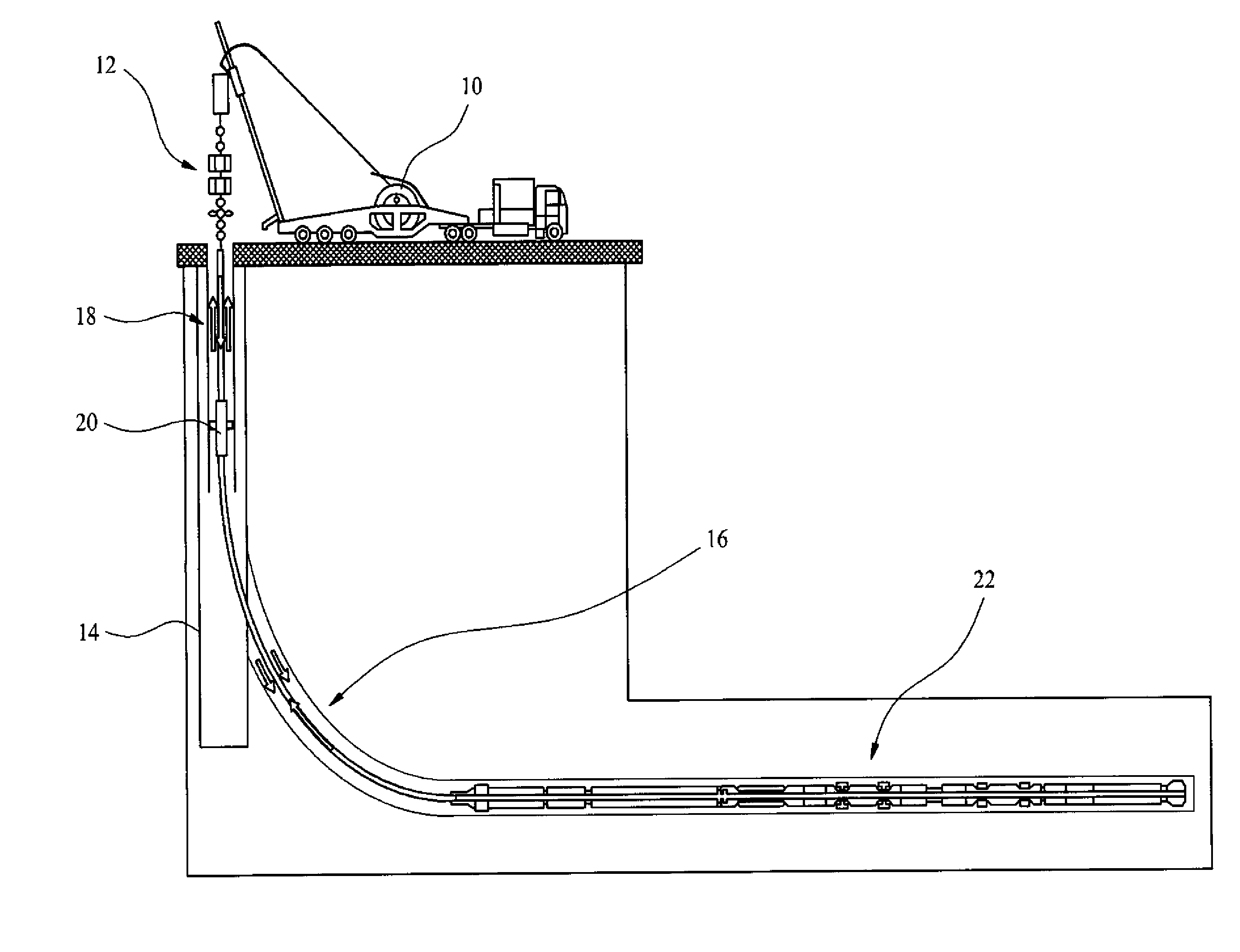

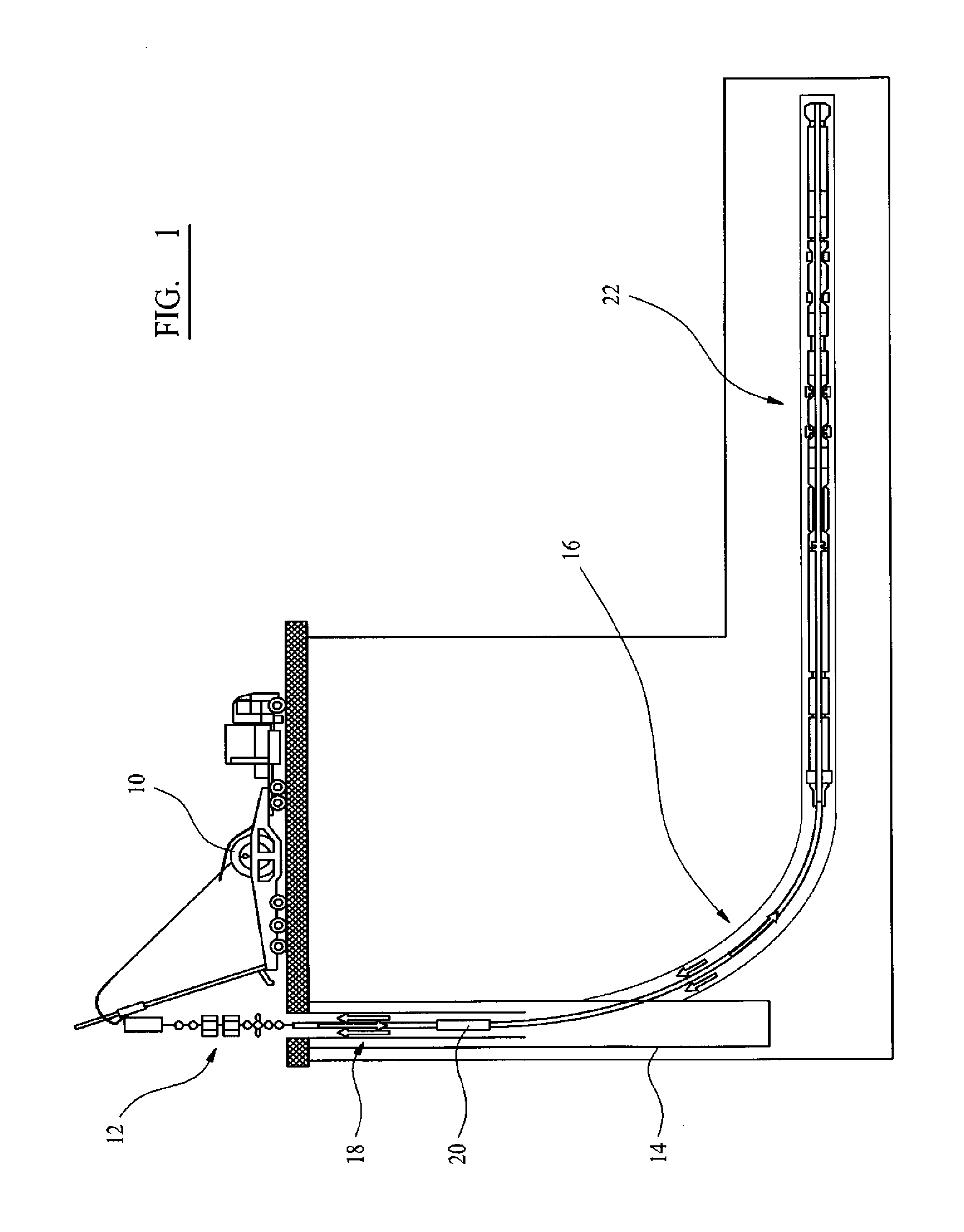

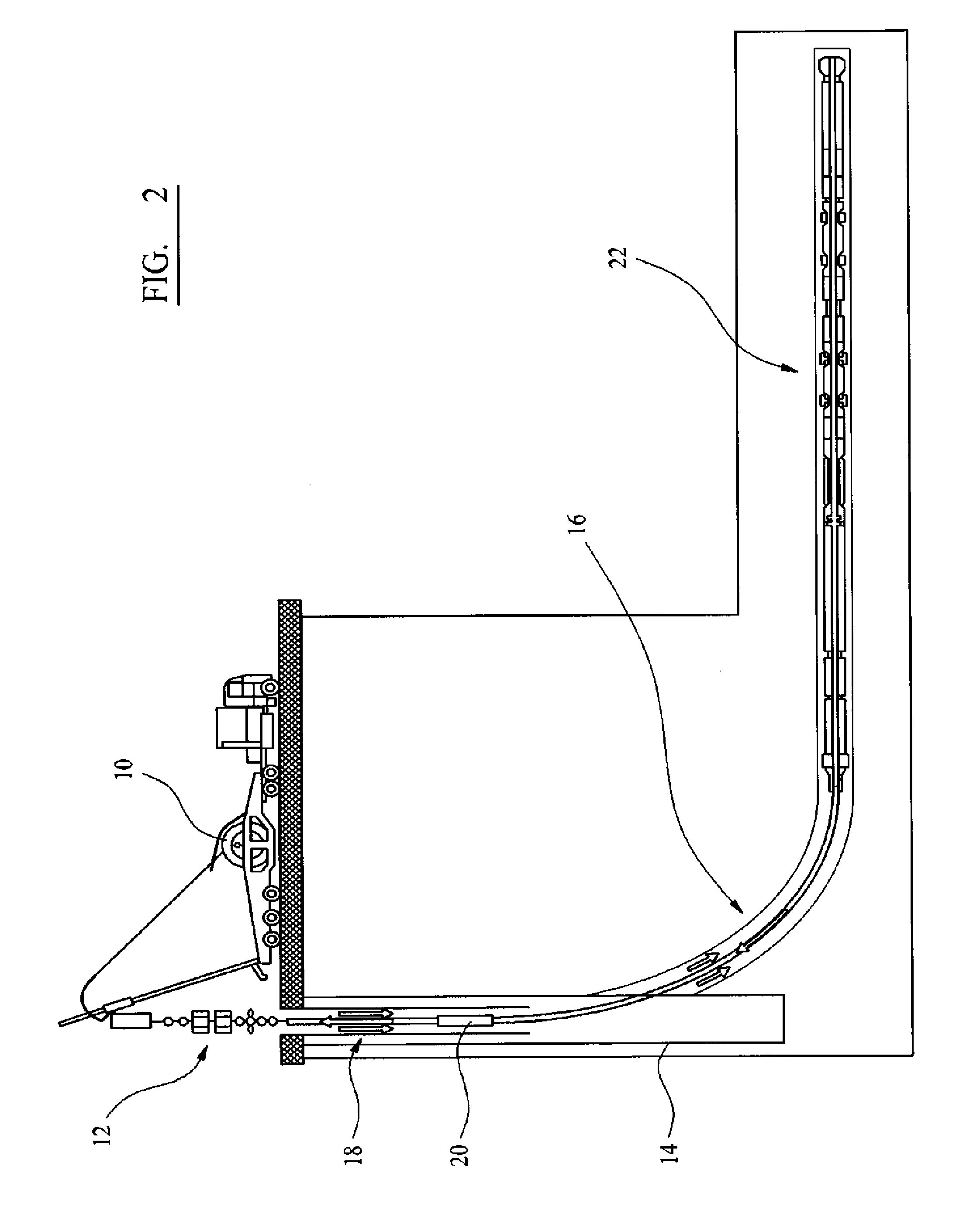

[0030]With reference to FIG. 1 a drilling operation is conducted using a conventional coiled tubing unit 10 and injector / pressure control setup 12 at the surface of the well 14 and is being used to drill a lateral well 16 extending away from the main well 14. The drilling apparatus comprises a coiled tubing conveyance system 18, a diverter 20 and a drilling system 22. The diverter 20 is adjustable to control the path through which the fluid can flow through the coiled tubing depending on the drilling conditions. The diverter is positioned in the main well 14, such that when the diverter is configured to direct fluid into the annulus the fluid will be released into a cased portion of the well.

[0031]As shown in FIG. 1 the coiled tubing conveyance system 18 can carry fluid from the surface to the section of the well being drilled. The fluid passes directly through the diverter 20 from the upper region of the CT conveyance system 18 above the diverter to the lower region of the CT conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com