Compound archery crossbow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Certain terminology is used herein for convenience only and is not to be taken as a limitation on the present invention. The terminology includes the words specifically mentioned, derivatives thereof, and words of similar import. The embodiments discussed herein are not intended to be exhaustive or to limit the invention to the precise form disclosed. Those embodiments are chosen and described to best explain the principles of the invention and its application and practical use and to enable others skilled in the art to best utilize the invention.

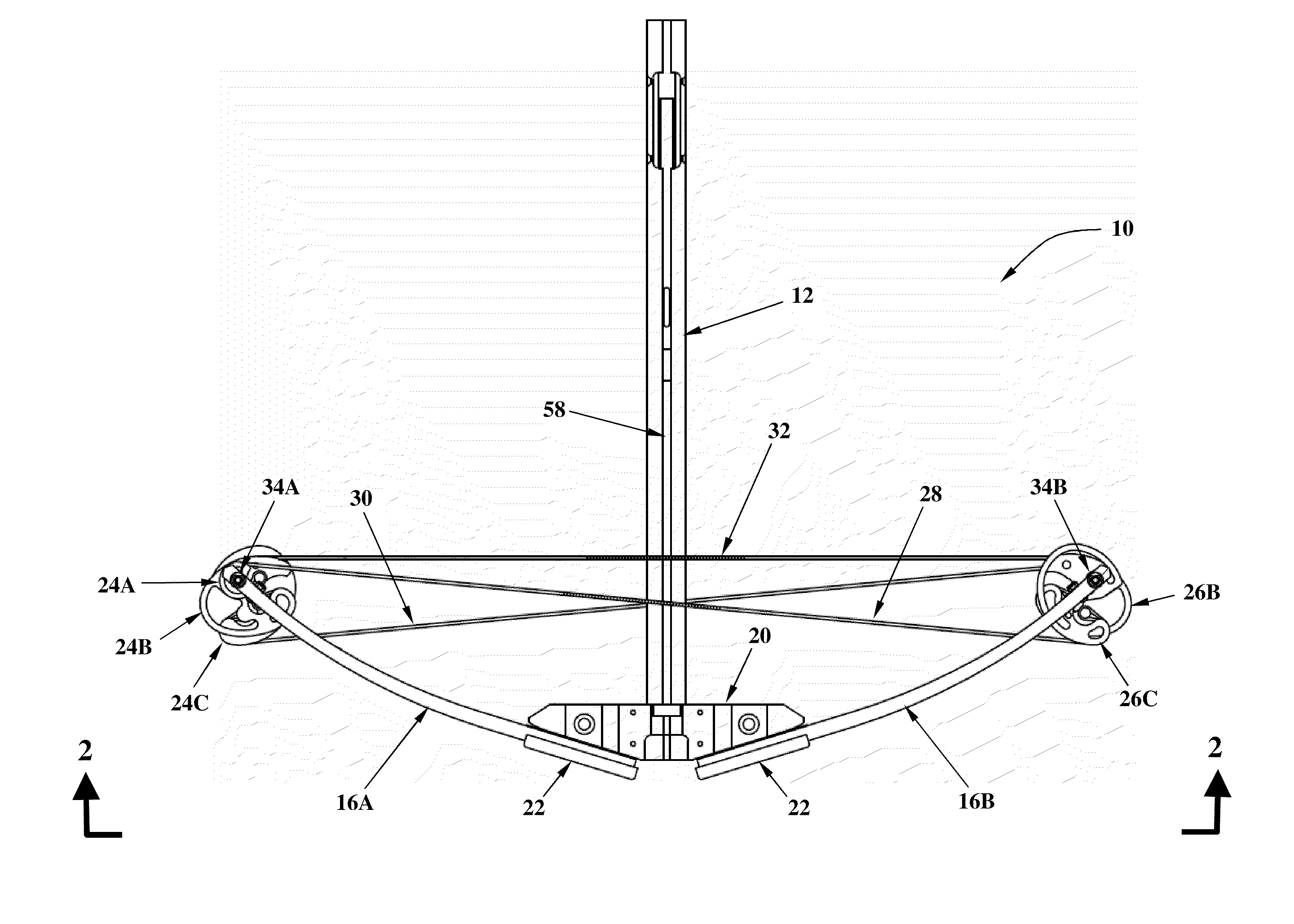

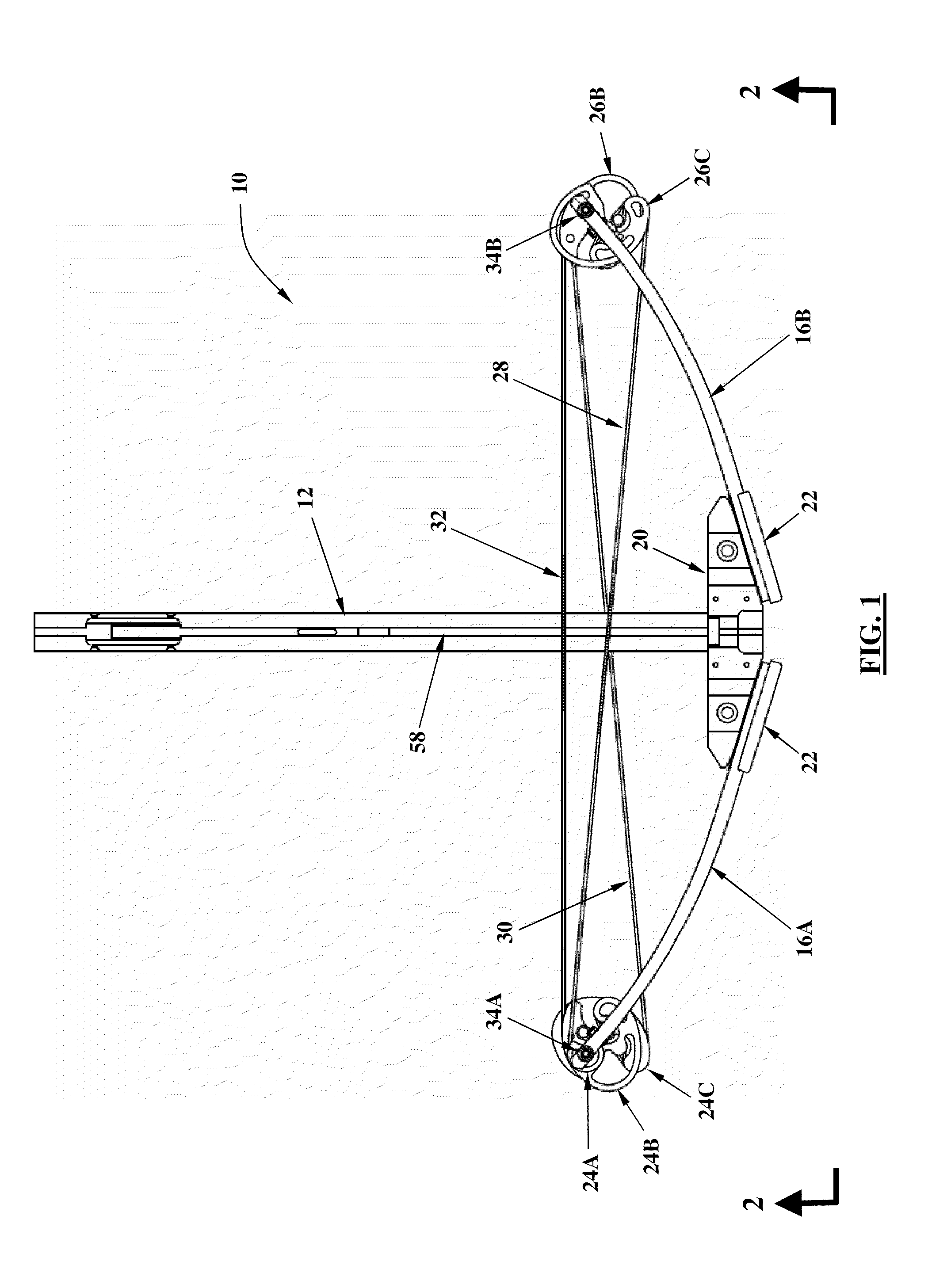

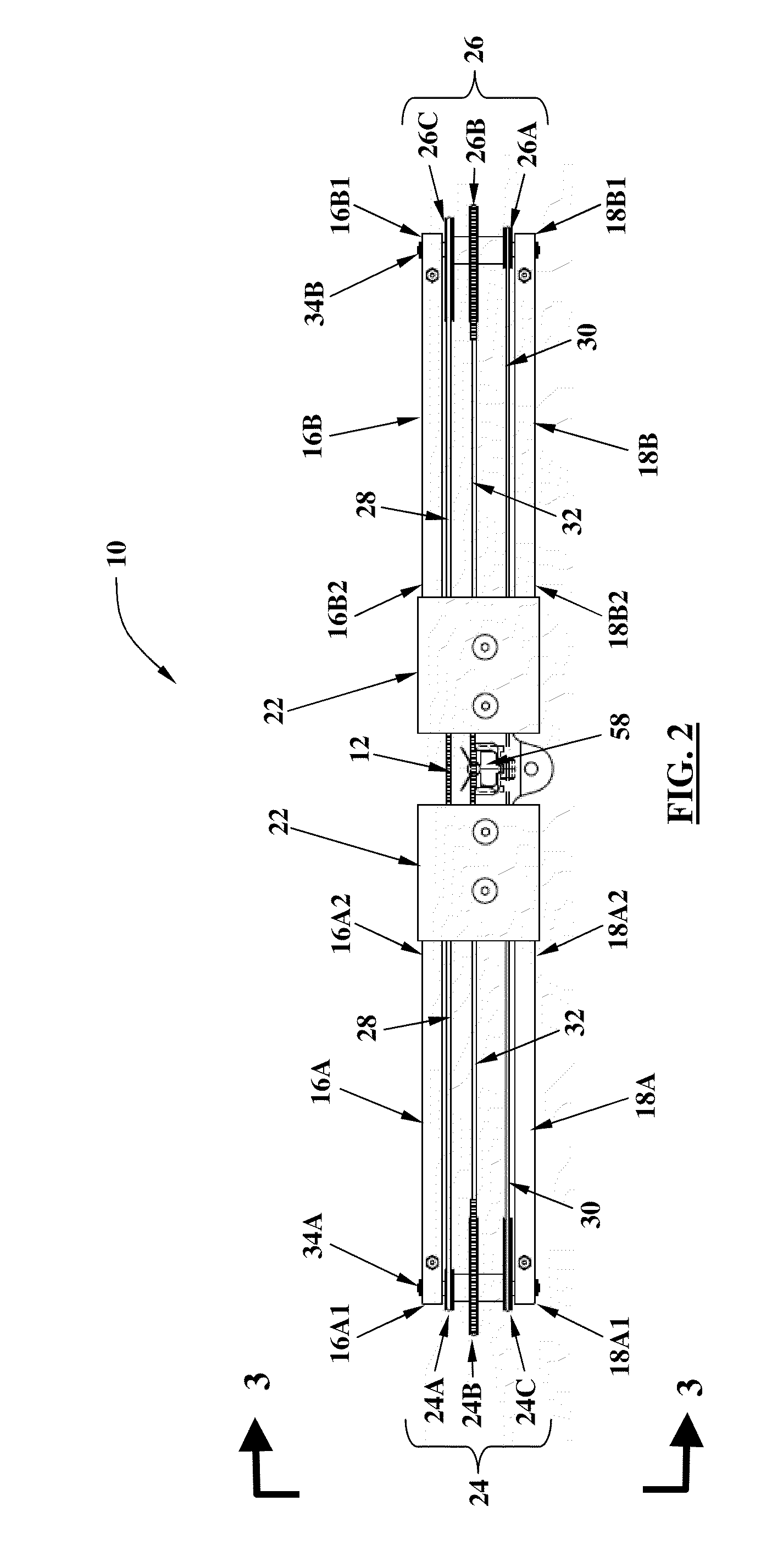

[0038]Referring now to the drawings, FIGS. 1-3 illustrate a first embodiment of the present invention directed to a compound archery crossbow 10 that may have a barrel 12 supported by a stock 14. The crossbow 10 may include an upper pair 16A & B and a lower pair 18A & B of limbs, wherein the upper pair of limbs 16A & B has a first member 16A with a distal end 16A1 and a proximal end 16A2 and a second member 16B with a distal end 16B1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com