Digital printing device with improved pre-printing textile surface treatment

a textile surface treatment and digital printing technology, applied in dyeing process, inking apparatus, transportation and packaging, etc., can solve the problems of catching ink drops and thin fibers that no longer stand out from the fabric, and achieve the effect of smooth printing surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

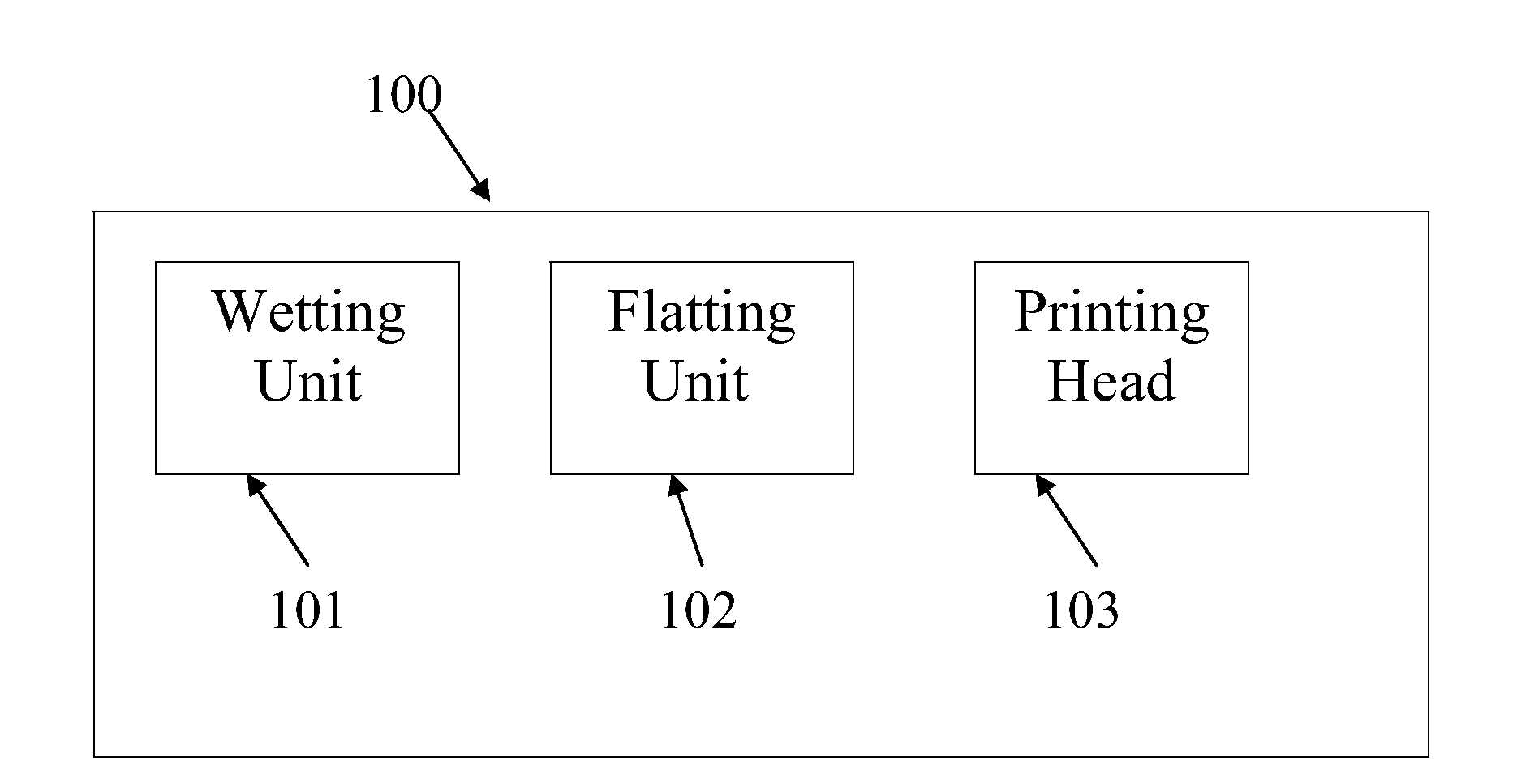

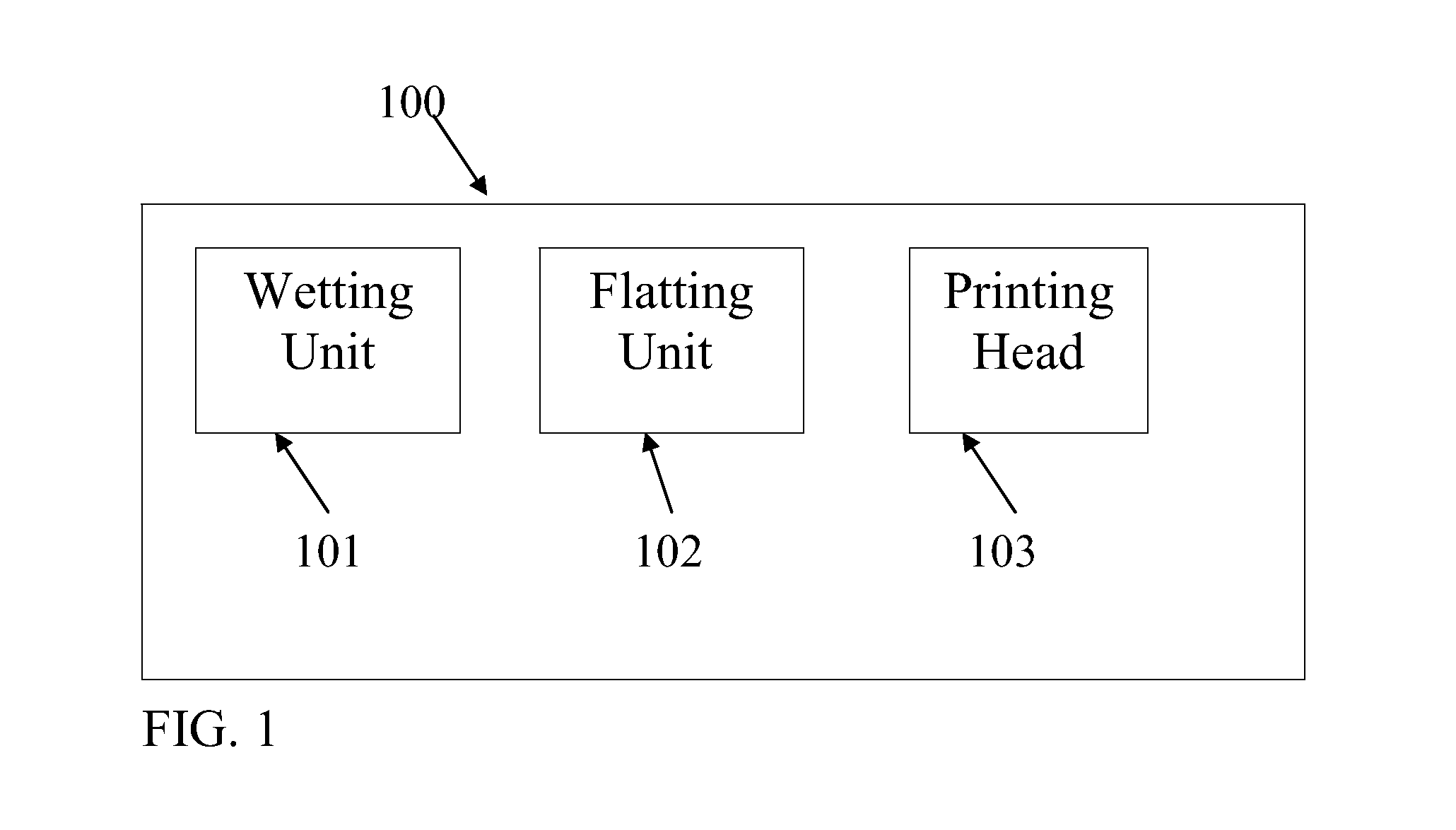

[0057]The present embodiments thus provide a digital printing machine for textiles, that presses and flattens the face of the fabric to be printed after wetting and before printing, when the fabric is still wet from the wetting process. Pressing causes uniform spread of the wetting solution and the outwardly extending fibers of a textile fabric to adhere to the fabric through surface tension due to the wetting, which adhering lasts until printing. Pressing may be provided by a flattening unit. The flattening unit applies or exerts mechanical pressure on the fabric to flatten the fibers of the fabric after wetting and before printing. Adhering the fibers to the fabric at this stage may eliminate the need for ironing the textile before printing.

[0058]The principles and operation of an apparatus and method according to the present invention may be better understood with reference to the drawings and accompanying description.

[0059]Before explaining at least one embodiment of the inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wetting | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com