Shell-and-Tube Heat Exchanger

a heat exchanger and shell technology, applied in the field of shellandtube heat exchangers, can solve the problems of high feed pressure inability to meet the requirements of use, etc., and achieve the effect of facilitating optimally short dwell times, low, medium or high viscosity and small heat exchange surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

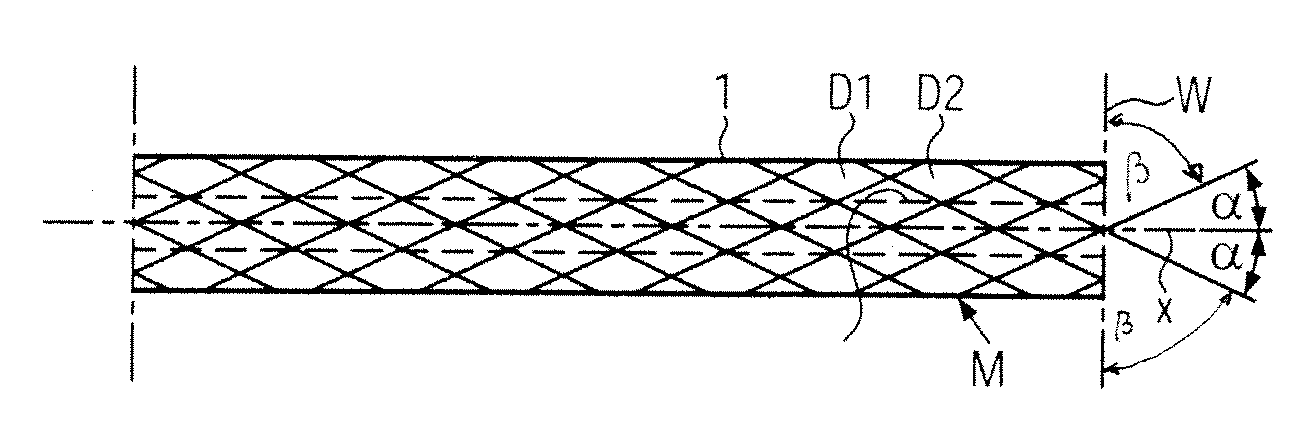

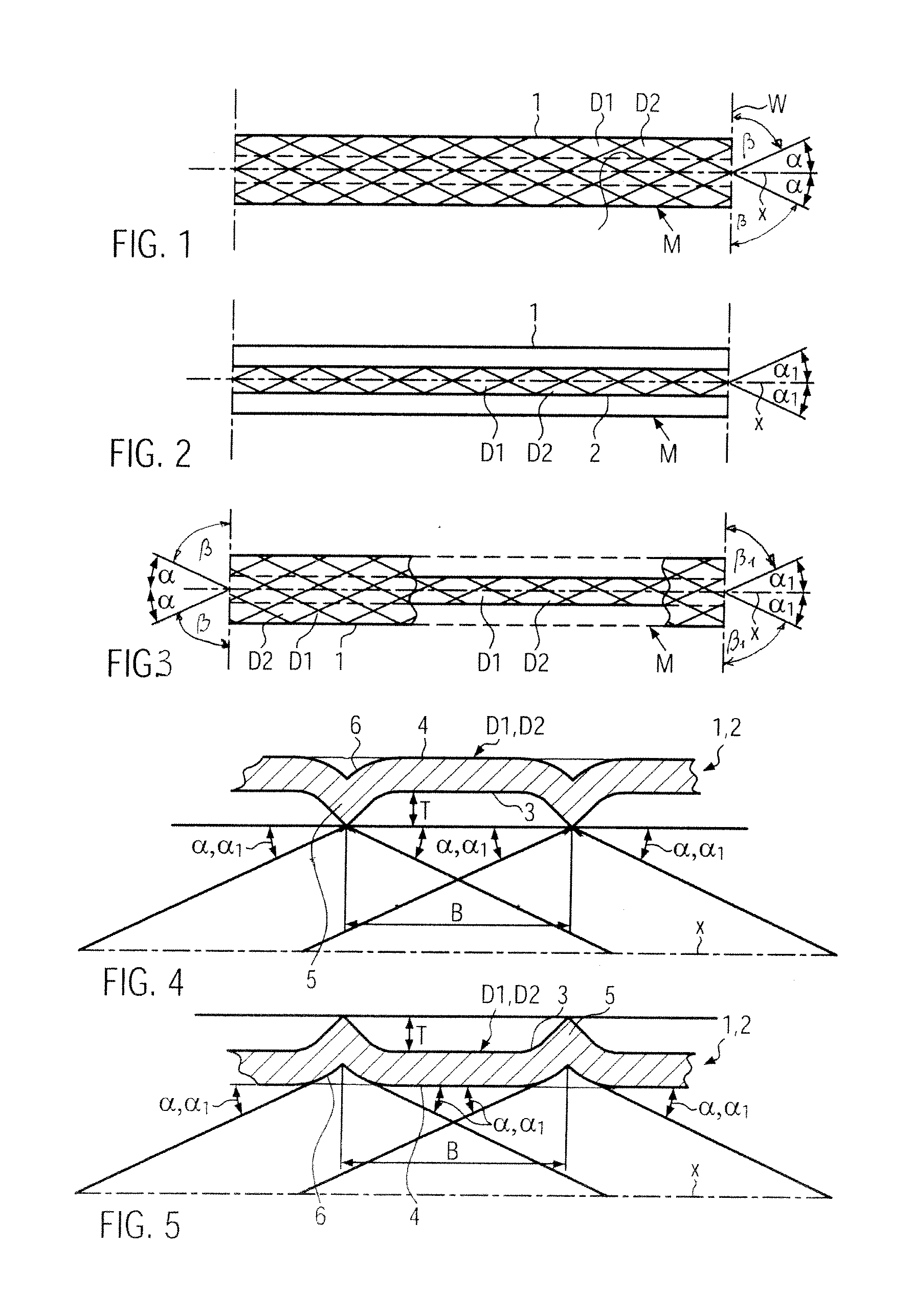

[0022]FIG. 1 illustrates a module M of a shell-and-tube heat exchanger W for the heat treatment of juices or juice-type foodstuff products with medium to high viscosities, for example, a viscosity of more than about 5 mPas, which comprises a jacket tube 1 and at least one approximately coaxial inner tube 2 accommodated inside the jacket tube 1 and spaced from the inner wall of the jacket tube 1. In the shell-and-tube heat exchanger W the module M is, for example, combined with further modules of the same type or similar which are not illustrated in order to form a treatment section of a certain conveying length. The product is either treated according to a recuperative method, i.e. product separated against product, for example, by the inner tube 2, or according to a method in which a heat transfer medium (steam or water) is used, whereby the heat transfer medium is separated against the product, for example, by the relevant inner tube 2. The relevant method is preferably operated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com